CHAPTER 8 EXTERNALS AND AUXILIARY CONTROL SYSTEM

COPYRIGHT© 2002 CANON INC.

2000

CANON iR1600/iR2000/iR1610/iR2010 SERIES REV.0 MAR. 2002

8-15

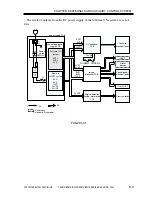

•

Fax Model

JP2

JP1

J21

J63

J72

J71

J32

J64

J33

J3

J1

J209

J34

BAT2

BAT1

J202

J206

J208

J204

J234

J81

J44

J41

J16

J35

J10

J42

J11

JP2

JP1

J204

BAT1

JP201

J202

J271

J216

J204

J210

J244

J221

J264

J209

J203

J211

J212

J263

J208

J206

J235

JP201

•

Non-Fax Model

F08-501-02

Summary of Contents for iR1600 Series

Page 24: ......

Page 26: ......

Page 96: ......

Page 110: ......

Page 112: ......

Page 144: ......

Page 146: ......

Page 158: ......

Page 160: ......

Page 182: ......

Page 216: ......

Page 218: ......

Page 248: ......

Page 250: ......

Page 284: ......

Page 298: ......

Page 300: ......

Page 312: ......

Page 314: ......

Page 366: ......

Page 368: ......

Page 378: ......

Page 604: ......

Page 606: ......

Page 648: ......

Page 650: ......

Page 652: ......

Page 656: ......

Page 660: ......

Page 665: ...COPYRIGHT 2002 CANON INC CANON FAX BOARD REV 0 MAR 2002 CHAPTER 1 INTRODUCTION...

Page 666: ......

Page 671: ...COPYRIGHT 2002 CANON INC CANON FAX BOARD REV 0 MAR 2002 CHAPTER 2 BASIC OPERATION...

Page 672: ......

Page 679: ...COPYRIGHT 2002 CANON INC CANON FAX BOARD REV 0 MAR 2002 CHAPTER 3 TROUBLESHOOTING...

Page 680: ......

Page 688: ......

Page 694: ......

Page 696: ......

Page 702: ......

Page 704: ......

Page 712: ......

Page 722: ......

Page 732: ......

Page 734: ......

Page 736: ......