COPYRIGHT © 2001 CANON INC.

2000 2000 2000 2000

CANON iR2200/iR2800/iR3300 REV.0 MAR. 2001

2-2 T

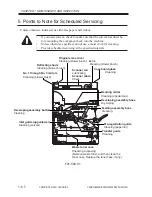

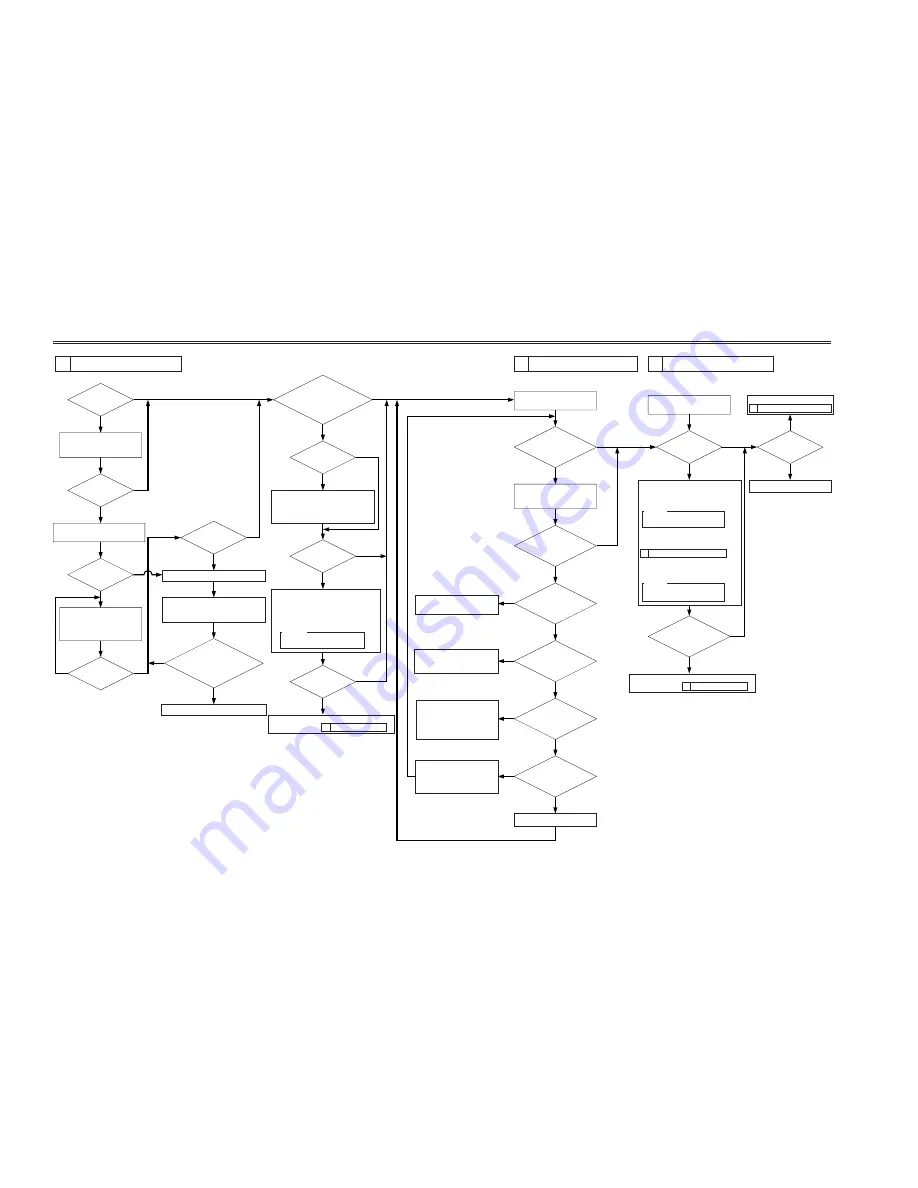

CHAPTER 2 IMAGE ADJUSTMENT BASIC PROCEDURE

YES

NO

NO

NO

NO

NO

NO

NO

NO

NO

NO

Is there a

vertical line in

the image?

YES

YES

YES

YES

YES

YES

YES

YES

YES

Is there a

vertical line in

the image?

Is there ea

vertical line in the

image?

Is the setting of the

following in service mode 485 µA:

DISPLAY>HV-STS>

PRIMARY?

Replace the composite power supply PCB.

Is there a

vertical line on the

surface of the

sleeve?

NO

NO

YES

NO

NO

NO

NO

NO

NO

YES

YES

YES

YES

Is there a

line on the surface

of the sleeve?

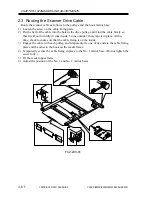

Clean the following:

[1] Laser mirror

[2] No. 1 mirror

Generate 10 test prints of the

following in service mode:

COPIER>TEST>PG.

TYPE6 (solid black)

Check the surface of the

developing sleeve by the naked eye.

Replace the drum unit.

Execute the following service mode:

COPIER>FUNCTION>DPC>D-GAMMA.

(initialization)

Is the image of TYPE6

(solid black) on test prints correct in

density and free

of fuzziness?

Is the image fuzzy?

Is the image

density appropriate?

Is the image

density appropriate?

Check the following,

and correct any fault:

[1] Feeding assembly for locking

[2] Transfer charging roller electrode

Adjust the setting of the following in

service mode:

COPIER>ADJUST>DEVELOP>DE-DC.

• If the image is light, decrease the setting.

• If the image is dark, increase the setting.

Caution:

Be sure to vary the setting in

equal amounts.

Check the image density by

generating test prints (TYPE5).

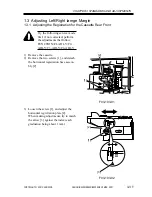

Is there an

appreciable difference

in density between left

and right of the

image?

YES

Clean the following:

[1] Laser mirror:

[2] No. 1 mirror

Are both rear and

front of the pre-exposure

lamp ON?

Is there a difference

in density between left and

right of the image?

YES

YES

NO

YES

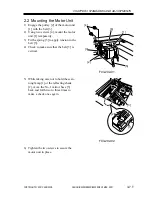

Is the developing

assembly securely locked

in place?

Is the coating of toner

on the developing

sleeve uneven?

Replace the pre-exposure

lamp unit.

Lock it securely. If the locking

mechanism has a fault, replace it.

Generate 10 test prints (TYPE6);

then, if the coating of toner on

the developing sleeve is uneven,

replace the developing assembly.

Is the

feeding assembly

(transfer charging roller) locked

securely in place?

Lock the feeding assembly

(transfer charging roller)

securely; if the locking

mechanism is faulty, replace the

transfer charging roller unit.

Replace the laser scanner unit.

Check the image density by

generating test prints (TYPE4).

Are the printouts

foggy?

Is the image density

of the tense prints (TYPE6)

appropriate?

Is there a fault in

the copy image?

2 Checking the Scanner Side.

End.

1 Making Initial Checks.

Increase the setting of the following in

service mode:

COPIER>ADJUST>DEVELOP>DE-DC.

Caution:

Be sure to vary the setting in

equal amounts.

However, if the setting has already been

changed under

3 Checking the Printer Side (1/3),

decrease the following in service mode:

COPIER>ADJUST>HV-PRI>P-DC.

Caution:

Be sure to vary the setting in

equal amounts.

3

Checking the Printer Side (1/3)

4 Checking the Printer Side (2/3)

5

Checking the Printer Side (3/3)

1 Making Initial Checks.

Replace the developing assembly, and make image

adjustments under

Replace the developing assembly, and make image

adjustments under

Go to

Summary of Contents for iR2200 Series

Page 8: ......

Page 12: ......

Page 30: ......

Page 32: ......

Page 54: ......

Page 86: ......

Page 90: ......

Page 94: ......

Page 96: ......

Page 124: ......

Page 142: ......

Page 152: ......

Page 160: ......

Page 168: ......

Page 178: ......

Page 180: ......

Page 222: ......

Page 224: ......

Page 278: ......

Page 280: ......

Page 298: ......

Page 300: ......

Page 324: ......

Page 368: ......

Page 386: ......

Page 388: ......

Page 404: ......

Page 414: ......

Page 416: ......

Page 422: ......

Page 424: ......

Page 434: ......

Page 436: ......

Page 440: ......

Page 468: ......

Page 473: ......

Page 550: ......

Page 552: ......

Page 658: ......

Page 704: ......

Page 706: ......

Page 754: ......

Page 756: ......

Page 760: ......