Chapter 14

14-5

[Detailed Discussions of BitSW14-6]

Select whether to enable or disable noise reduction mode during terminal temperature rises. Select "On" to start slowdown at a temperature lower than normal when

printing on smaller-sized paper than B4. Slowdown control thus enabled prevents the thermal degradation of the fusing film grease, assuring smooth sliding among

the fixing film, heater and film guide to cut squeaks.

[BitSwitch 15]

[Detailed Discussions of BitSW15-0]

Select whether to inhibit automatic delivery tray replacement while running jobs with an inner two-way tray mounted in position. Select "On" to inhibit automatic

tray replacement.

[Detailed Discussions of BitSW15-1]

Select whether to halt stapling job when a finisher installed has run out of staples. Select "On" to halt staple jobs when the finisher has run out of staples.

[Detailed Discussions of BitSW15-2]

Select whether to display a tray full message when the maximum allowable stapled document count is exceeded with a finisher installed. Select "On" not to display

the message.

[Fuser temp.-Bypass]

Lower the fixing temperature from the target temperature setting to reduce the chances of fixing offsets and curled or stuck delivered sheets occurring with paper

picked from a manual feed tray.

[Fuser temp.-Tray1]

Lower the fixing temperature from the target temperature setting to reduce the chances of fixing offsets and curled or stuck delivered sheets occurring with paper

picked from cassette 1.

[Fuser temp.-Tray2]

Lower the fixing temperature from the target temperature setting to reduce the chances of fixing offsets and curled or stuck delivered sheets occurring with paper

picked from cassette 2.

[Fuser temp.-Tray3]

Lower the fixing temperature from the target temperature setting to reduce the chances of fixing offsets and curled or stuck delivered sheets occurring with paper

picked from cassette 3.

[Fuser temp.-Tray4]

Lower the fixing temperature from the target temperature setting to reduce the chances of fixing offsets and curled or stuck delivered sheets occurring with paper

picked from cassette 4.

[Film Speed-Bypass]

Change the fixing film speed to reduce the chances of streaks appearing in the trailing edge of images caused by shocks from the fixing roller out of position while

picking paper from a manual feed tray.

[Film Speed-Tray]

Change the fixing film speed to reduce the chances of streaks appearing in the trailing edge of images caused by shocks from the fixing roller out of position while

picking paper from a cassette.

[Define U1 Paper Size]

[Define U2 Paper Size]

[Define U3 Paper Size]

With a special paper compatibility kit (cassette size adjuster) installed, set the cassette paper size lever to paper size groups U1 to U3 to set the paper sizes listed

below.

[Print Test-Page]

Not used.

[Print Test-Interval]

Not used.

[B4-Large/Small]

Use it to specify whether B4 paper should be counted as large-size paper.

If 'Large' is selected, B4 paper will be counted as large-size paper.

If 'Small' is selected, on the other hand, B4 paper will be counted as small-size paper.

[Waste Toner Full]

Select whether to display the waste toner full warning as a drum replacement required message or as service call displayed on the control panel. Select 'Operation

call' to display a rum replacement required message on an operation call. Select 'Service call' to display service call.

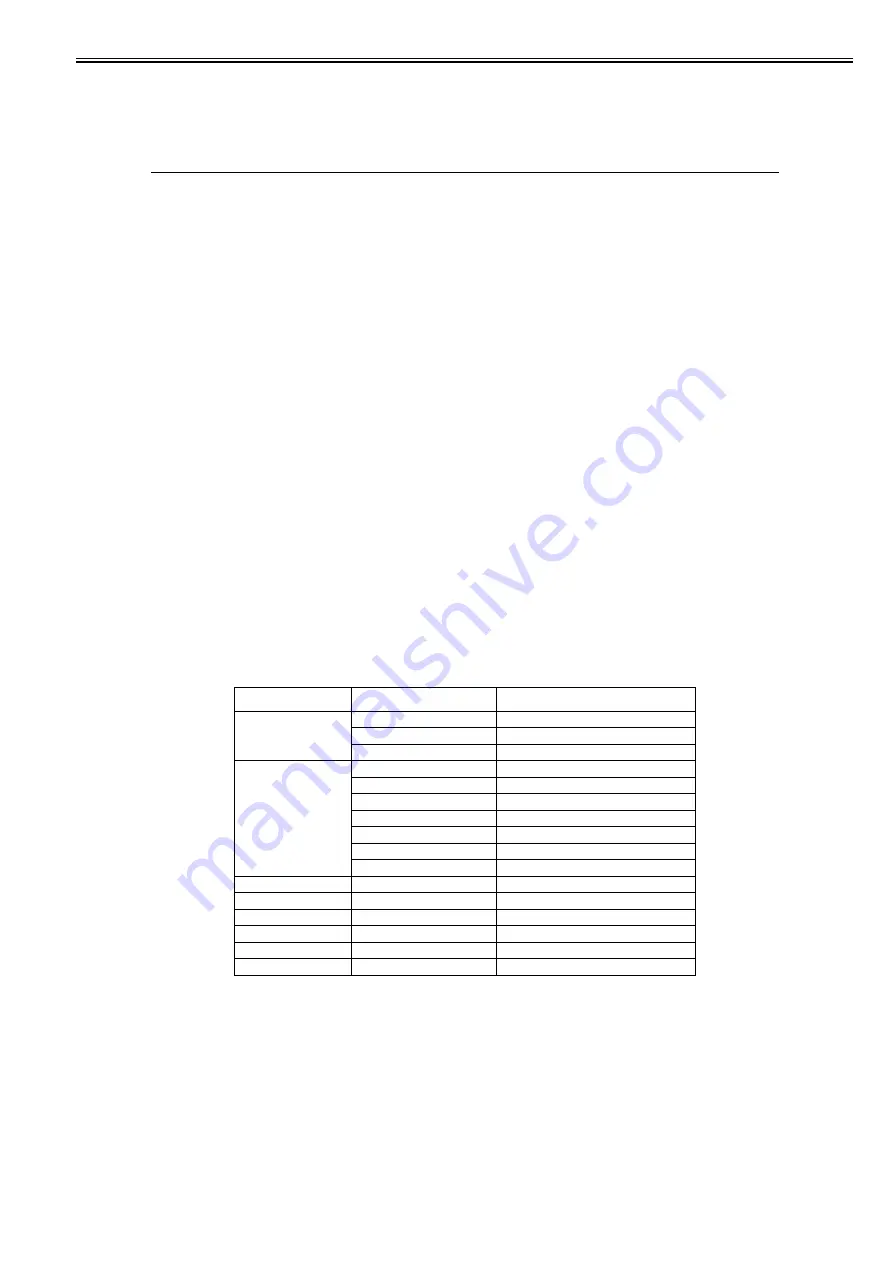

Setting item.

Function

Setting value

SW15-0

Inhibit automatic delivery tray replacement while running jobs

On, Off

SW15-1

Halt stapling job when out of staples

On, Off

SW15-2

Inhibit tray full indication while the stapled document count is exceeded

On, Off

Paper size group

Setting (*default)

Paper name

U1

29

A-LTR

31*

G-LTR

40

8K

U2

24*

Foolscap

26

Officio

27

E-Officio

28

B-Officio

36

A-Offico

37

M-Officio

39

16K

U3

25

A-Foolscap

30

A-LTR-R

32

G-LTR-R

34*

G-LGL

35

Folio

16KR

Summary of Contents for iR2422 series

Page 1: ...May 12 2014 Service Manual iR2422 2420 2320 2318 Series...

Page 2: ......

Page 6: ......

Page 16: ...Contents...

Page 17: ...Chapter 1 Introduction...

Page 18: ......

Page 20: ......

Page 50: ......

Page 51: ...Chapter 2 Installation...

Page 52: ......

Page 54: ......

Page 58: ...Chapter 2 2 4 7 Left cover front 15 Right cover upper 8 Manual feed tray 16 Right cover lower...

Page 62: ...Chapter 2 2 8 8 Manual feed tray 16 Right cover lower...

Page 64: ...Chapter 2 2 10 8 Manual feed tray 16 Right cover lower...

Page 89: ...Chapter 2 2 35...

Page 90: ......

Page 91: ...Chapter 3 Main Controller...

Page 92: ......

Page 94: ......

Page 102: ......

Page 103: ...Chapter 4 Original Exposure System...

Page 104: ......

Page 135: ...9 Remove the reader heater left 1 Connector 2 1 pc Screw 3 1 pc F 4 73 2 3 1...

Page 136: ......

Page 137: ...Chapter 5 Laser Exposure...

Page 138: ......

Page 140: ......

Page 148: ...Chapter 5 5 8...

Page 149: ...Chapter 6 Image Formation...

Page 150: ......

Page 152: ......

Page 165: ...Chapter 7 Pickup Feeding System...

Page 166: ......

Page 192: ...Chapter 7 7 24...

Page 193: ...Chapter 8 Fixing System...

Page 194: ......

Page 196: ......

Page 207: ...Chapter 9 External and Controls...

Page 208: ......

Page 229: ...Chapter 10 Maintenance and Inspection...

Page 230: ......

Page 232: ......

Page 235: ...Chapter 11 Standards and Adjustments...

Page 236: ......

Page 238: ......

Page 240: ...Chapter 11 11 2...

Page 241: ...Chapter 12 Correcting Faulty Images...

Page 242: ......

Page 244: ......

Page 256: ......

Page 257: ...Chapter 13 Self Diagnosis...

Page 258: ......

Page 260: ......

Page 269: ...Chapter 14 Service Mode...

Page 270: ......

Page 272: ......

Page 287: ...Chapter 15 Upgrading...

Page 288: ......

Page 290: ......

Page 295: ...Chapter 16 Service Tools...

Page 296: ......

Page 298: ......

Page 300: ......

Page 301: ...Chapter 17 Backup Data...

Page 302: ......

Page 303: ...Contents Contents 17 1 Backup Data 17 1...

Page 304: ......

Page 306: ......

Page 307: ...May 12 2014...

Page 308: ......