COPYRIGHT © 2000 CANON INC.

2000 2000 2000 2000

CANON iR5000/iR6000 REV.0 JULY 2000

CHAPTER 3 LASER EXPOSURE SYSTEM

3-4 P

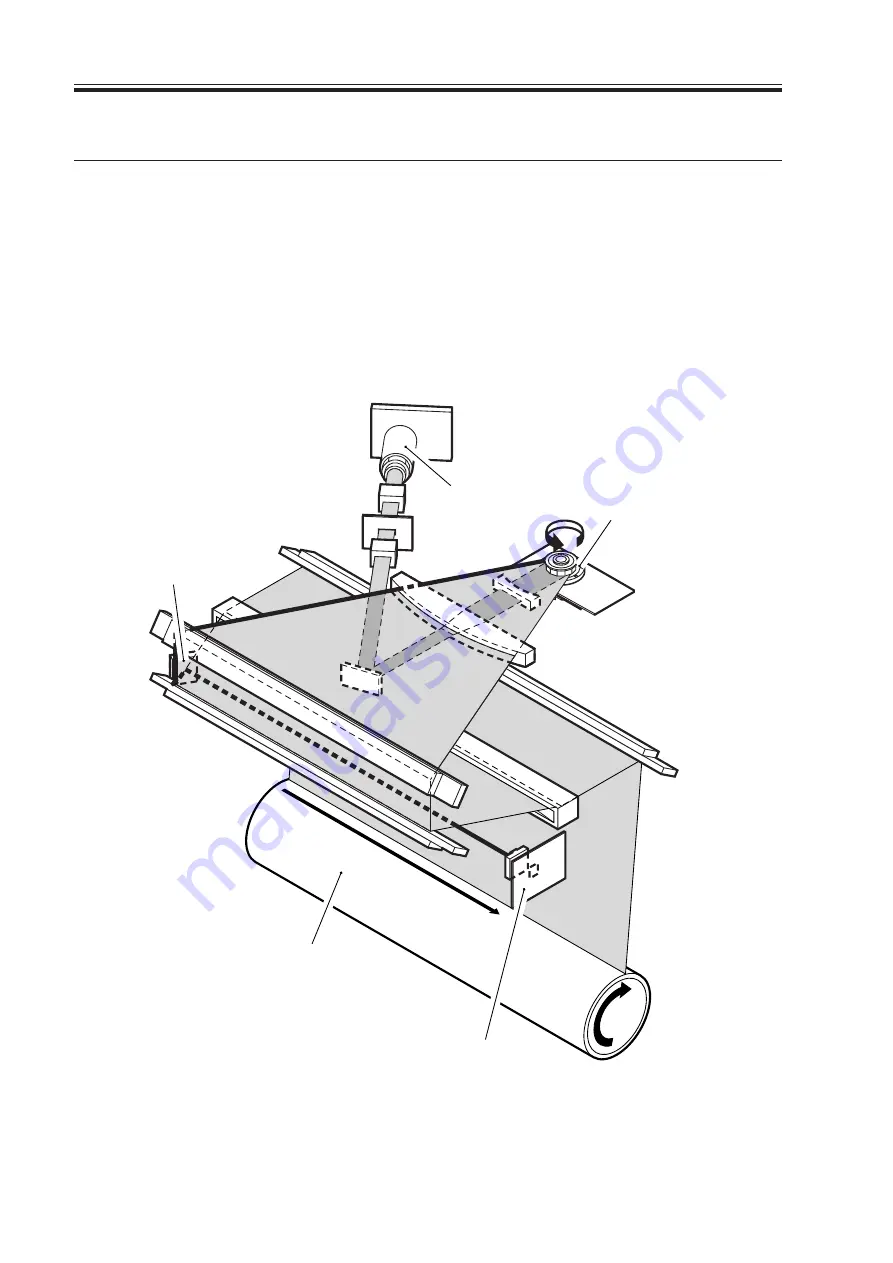

2. Generating Sync Signals

2.1 Outline

The BD signal used to synchronize video signals for laser scanning direction is generated

by the BD PCB with reference to the laser beam reflected by the BD mirror, mounted along

the path of the laser beam.

The CCD/AP PCB reads image signals from the CCD, and sends them to the controller

unit. The controller unit performs image processing, and the signals are sent to the laser

driver PCB as video signals through the DC controller PCB; they are then sent to the laser

unit as laser intensity control signals in sequence.

F03-201-01 Construction of the Control System

12-facet polygon

mirror

Laser unit

BD mirror

Photosensitive drum

BD PCB

Download Free Service Manual at http://printer1.blogspot.com

Summary of Contents for IR5000 - iR B/W Laser

Page 10: ...Download Free Service Manual at http printer1 blogspot com ...

Page 14: ...Download Free Service Manual at http printer1 blogspot com ...

Page 46: ...Download Free Service Manual at http printer1 blogspot com ...

Page 64: ...Download Free Service Manual at http printer1 blogspot com ...

Page 92: ...Download Free Service Manual at http printer1 blogspot com ...

Page 94: ...Download Free Service Manual at http printer1 blogspot com ...

Page 98: ...Download Free Service Manual at http printer1 blogspot com ...

Page 106: ...Download Free Service Manual at http printer1 blogspot com ...

Page 136: ...Download Free Service Manual at http printer1 blogspot com ...

Page 138: ...Download Free Service Manual at http printer1 blogspot com ...

Page 154: ...Download Free Service Manual at http printer1 blogspot com ...

Page 166: ...Download Free Service Manual at http printer1 blogspot com ...

Page 176: ...Download Free Service Manual at http printer1 blogspot com ...

Page 198: ...Download Free Service Manual at http printer1 blogspot com ...

Page 213: ...Download Free Service Manual at http printer1 blogspot com ...

Page 299: ...Download Free Service Manual at http printer1 blogspot com ...

Page 379: ...Download Free Service Manual at http printer1 blogspot com ...

Page 381: ...Download Free Service Manual at http printer1 blogspot com ...

Page 425: ...Download Free Service Manual at http printer1 blogspot com ...

Page 473: ...Download Free Service Manual at http printer1 blogspot com ...

Page 475: ...Download Free Service Manual at http printer1 blogspot com ...

Page 521: ...Download Free Service Manual at http printer1 blogspot com ...

Page 535: ...Download Free Service Manual at http printer1 blogspot com ...

Page 543: ...Download Free Service Manual at http printer1 blogspot com ...

Page 557: ...Download Free Service Manual at http printer1 blogspot com ...

Page 559: ...Download Free Service Manual at http printer1 blogspot com ...

Page 565: ...Download Free Service Manual at http printer1 blogspot com ...

Page 613: ...Download Free Service Manual at http printer1 blogspot com ...

Page 616: ...Download Free Service Manual at http printer1 blogspot com ...

Page 691: ...Download Free Service Manual at http printer1 blogspot com ...

Page 693: ...Download Free Service Manual at http printer1 blogspot com ...

Page 797: ...Download Free Service Manual at http printer1 blogspot com ...

Page 819: ...Download Free Service Manual at http printer1 blogspot com ...

Page 821: ...Download Free Service Manual at http printer1 blogspot com ...

Page 831: ......

Page 837: ......