CHAPTER 2 STANDARDS AND ADJUSTMENTS

2-14

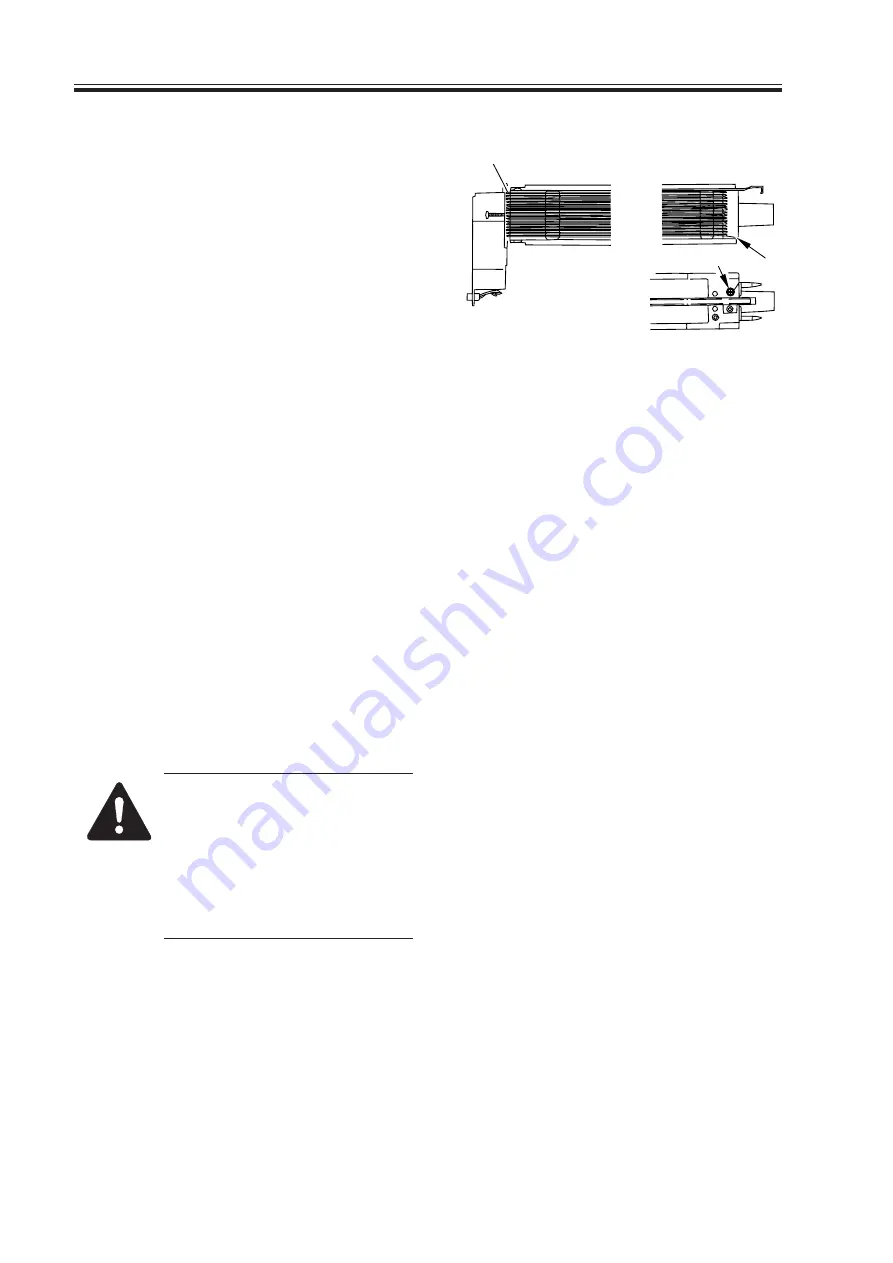

5) Cut the twisted charging wire (excess)

with nippers.

6) Hook the loop on stud A.

7) After routing the wire for 31 runs, lead

it through section B, and give it a half

turn; then, put it between the washer

and the motor unit, and wind it once

around the mounting screw (clockwise),

and secure it in place with a mounting

screw.

F02-203-03

8) Cut the excess of the charging wire with

nippers.

9) Tighten the mounting screw loosened in

step 3).

Keep tightening until the tension of the

grid wire is even.

Be sure to pay attention to avoid defor-

mation (slack) of the charging assembly

(as by tightening the mounting screw

found on the front of the left/right

shielding plate early).

10) Tighten the mounting screws loosened

in steps 1) and 2).

11) Wipe the grid wire with lint-free paper

moistened with alcohol.

1. Check to make sure that the

grid wire is free of bending

and twisting.

2. Be sure that the runs are laid

at equal intervals (i.e., the

wire is in the groove of the

block).

Stud A

Screw

B

Summary of Contents for IR5000 - iR B/W Laser

Page 72: ...CHAPTER 2 STANDARDS AND ADJUSTMENTS 2 52 Blank Page ...

Page 104: ......

Page 224: ......

Page 234: ......