Chapter 12

12-6

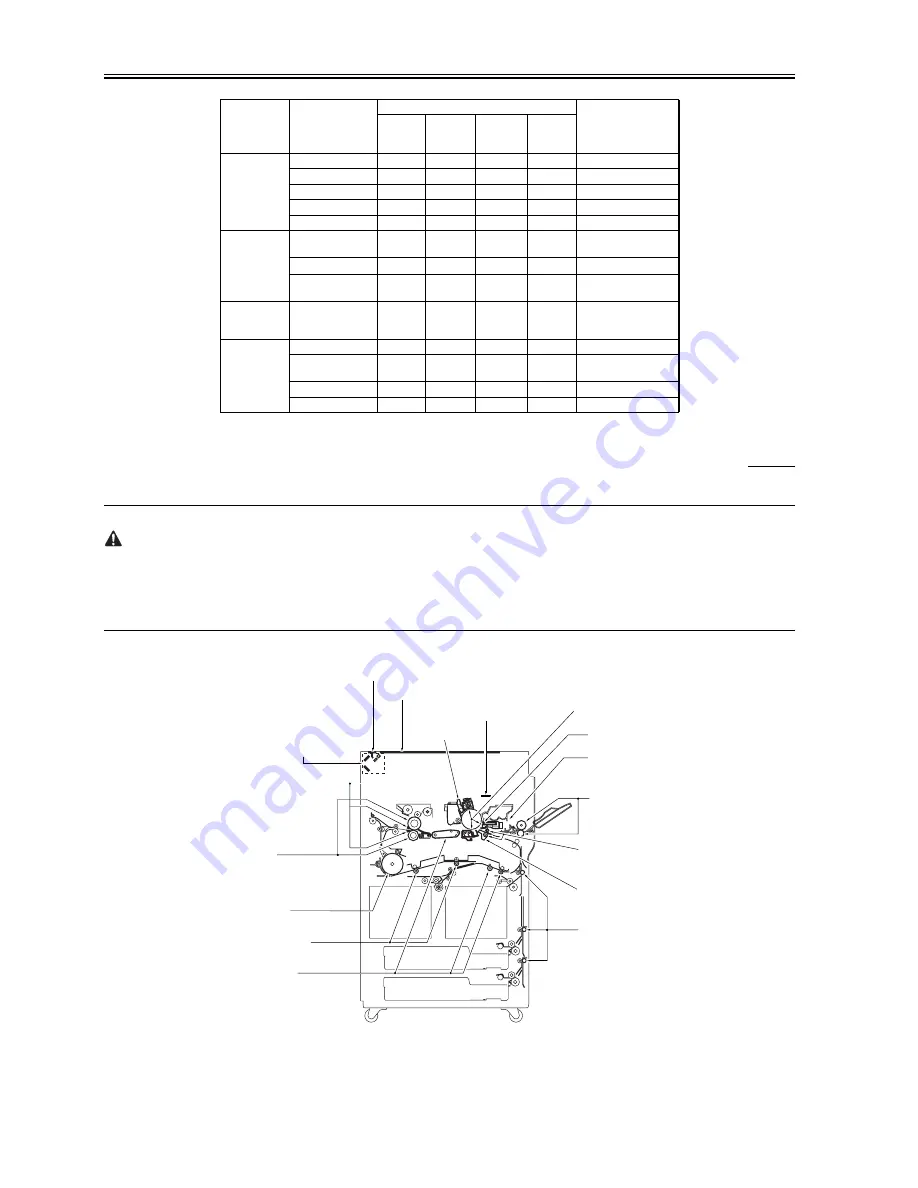

12.3.4 Points to Note for Periodical Servicing

0009-5841

Unless otherwise instructed, clean with lint-free paper and alcohol.

- Make a thorough check of the block (front, rear) for melting by leakage, deformation by heat, cracking, discoloration (yellowing). If a fault is found,

replace the part with a new one immediately.

- Check the block (front, rear) including its inside.

- Do not use a cloth on which metal powder is found.

- If you have used solvent, make sure that the part has dried completely before mounting it back to the machine.

- Do not use a moist cloth unless specifically indicated.

- Be sure to provide scheduled servicing/replacement at the specified intervals.

F-12-1

Fixing

assembly

Inlet guide

Clean

Web

Inspect

Oil dish

Clean

Thermistor unit

Clean

Replace

Sub thermistor

Clean

Replace

Delivery

assembly

Separation claw

(upper, lower)

Clean

Internal delivery roll

Clean

External delivery

roll

Clean

Waste toner

collection

area

Waste toner box

Inspect

Inspect case, and

remove toner.

Pickup/ feeding

assembly

Transfer guide

Clean

Registration

roller (upper, lower)

Clean

Feeding belt

Clean

Feeding rollers

Clean

Unit name

Part

Intervals

Remarks

Upon

installatio

n

every

250,000

every

500,000

every

1,000,000

Pickup/feeding roller

Registration roller

Transfer guide

Vertical path roller

Pre-exposure glass

Reversing roller

Duplex Feeding Roller

(right/left)

Dust-collecting roller

Disposing of toner.

Separation claw, fixing

Clean with solvent

and lint-free paper.

Fixing roller

Use cleaning oil and

lint-free paper.

Reflecting plate

Clean with a blower brush.

Primary/Transfer/Separation/

Dry wipe with lint-free paper;

then, clean with alcohol.

Dust-proofing glass

Dry wipe with lint-free paper.

Dry wipe with lint-free paper.

ADF reading glass

Copyboard glass

Clean it with a blower brush;

if dirt is excessive, dry wipe

with lint-free paper.

No. 1 through No. 3 mirrors

Scanning lamp

Feeding assembly

Clean with a moist cloth;

Developing assembly

base

Clean with a moist

Note 1: Do to leave traces of water.

assembly inlet guide

(upper/lower)

see Note 1.

Pre-transfer charging assembly

cloth; see Note 1.

Summary of Contents for iR5570 Series

Page 1: ...Mar 29 2005 Service Manual iR6570 5570 Series ...

Page 2: ......

Page 6: ......

Page 26: ...Contents ...

Page 27: ...Chapter 1 Introduction ...

Page 28: ......

Page 30: ......

Page 55: ...Chapter 2 Installation ...

Page 56: ......

Page 58: ...Contents 2 9 3 Mounting the Cassette Heater 2 34 ...

Page 98: ......

Page 99: ...Chapter 3 Basic Operation ...

Page 100: ......

Page 102: ......

Page 110: ......

Page 111: ...Chapter 4 Main Controller ...

Page 112: ......

Page 114: ......

Page 135: ...Chapter 5 Original Exposure System ...

Page 136: ......

Page 181: ...Chapter 6 Laser Exposure ...

Page 182: ......

Page 184: ......

Page 192: ......

Page 193: ...Chapter 7 Image Formation ...

Page 194: ......

Page 198: ......

Page 259: ...Chapter 8 Pickup Feeding System ...

Page 260: ......

Page 350: ......

Page 351: ...Chapter 9 Fixing System ...

Page 352: ......

Page 401: ...Chapter 10 External and Controls ...

Page 402: ......

Page 406: ......

Page 448: ......

Page 449: ...Chapter 11 MEAP ...

Page 450: ......

Page 452: ......

Page 455: ...Chapter 12 Maintenance and Inspection ...

Page 456: ......

Page 458: ......

Page 468: ......

Page 469: ...Chapter 13 Standards and Adjustments ...

Page 470: ......

Page 505: ...Chapter 14 Correcting Faulty Images ...

Page 506: ......

Page 508: ......

Page 537: ...Chapter 15 Self Diagnosis ...

Page 538: ......

Page 540: ......

Page 565: ...Chapter 16 Service Mode ...

Page 566: ......

Page 568: ......

Page 633: ...Chapter 17 Upgrading ...

Page 634: ......

Page 636: ......

Page 641: ...Chapter 17 17 5 F 17 4 HDD Boot ROM Flash ROM System Software ...

Page 646: ...Chapter 17 17 10 F 17 11 8 Click START F 17 12 ...

Page 675: ...Chapter 17 17 39 F 17 59 2 Select the data to download F 17 60 3 Click Start ...

Page 677: ...Chapter 18 Service Tools ...

Page 678: ......

Page 680: ......

Page 683: ...Mar 29 2005 ...

Page 684: ......