HTTP://WWW.FIXCLUB.COM.CN

Chapter 2

2-2

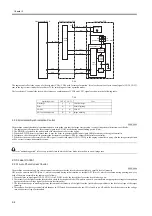

2.2 Basic Sequense

2.2.1 Basic Operation Sequence

0007-9885

The operation sequence of this printer is controller by the microprocessor (CPU) on the engine controller PCB. The following diagram shows the purposes

of each periods from power ON until the main motor stops after the completion of printing. See the timing chart.

T-2-1

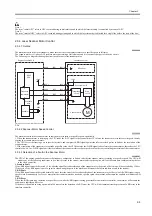

2.2.2 Power-on sequence

0007-9887

The following is the sequence from power ON until the engine controller enters STBY mode.

1) Power ON

2) CPU initialization

3) Video interface communication start

4) Residual paper check

Checks the sensors for any residual paper.

5) Main motor initial drive

6) Fixing heater initial drive

Drive the fixing heater so that the fixing unit reaches its targeted temperature of 100 deg C.

7) Scanner motor initial drive

8) High-voltage control

Clean the transfer sharging roller.

9) Failure/ abnormality check

Detects scanner failure, fixing unit failure and door open during the periods mentioned

above.

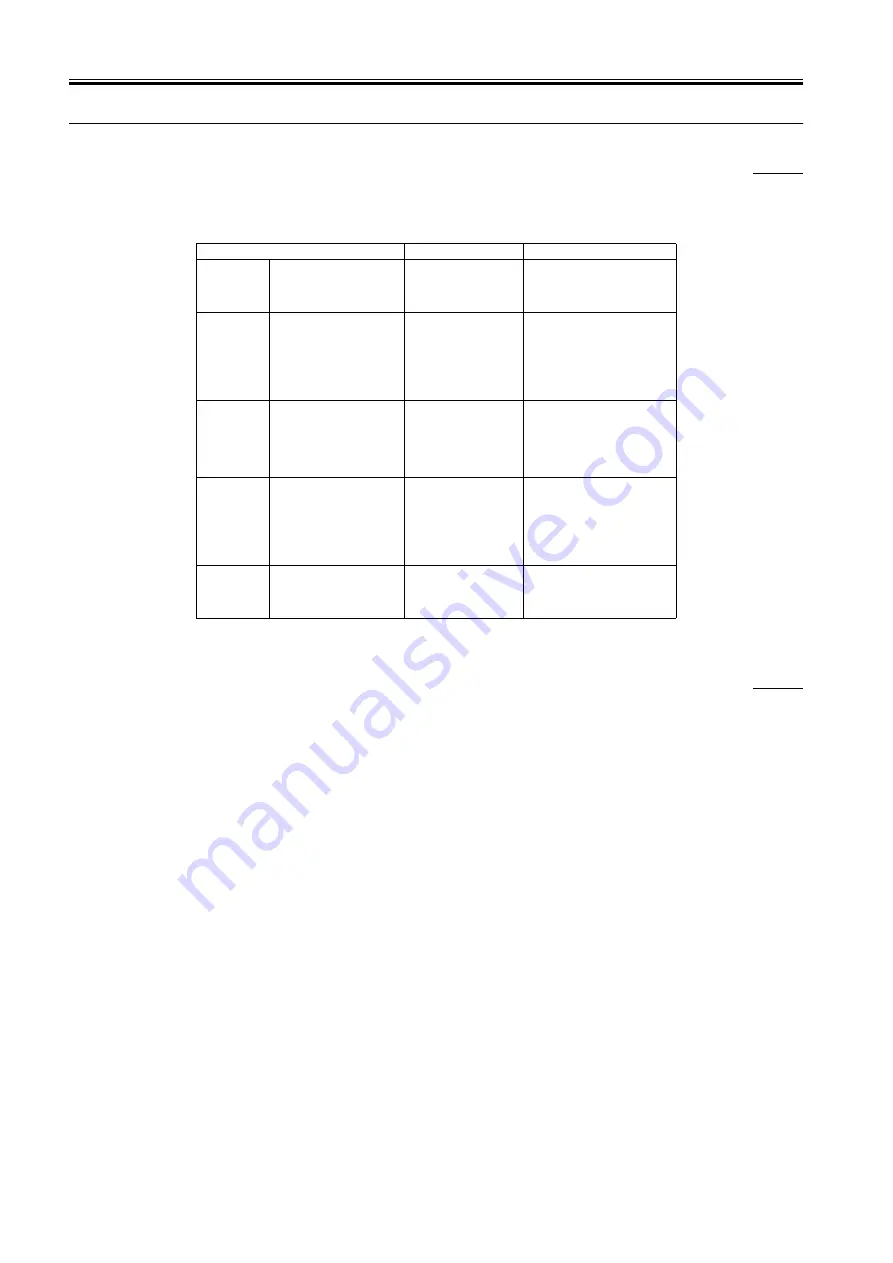

Period

Purpose

Remarks

WAIT

(Wait)

From power-ON until the end

of the main motor initial

rotation.

To clean the drum surface

of potential and to clean

the transfer charging

roller.

Toner cartridge in/out detection is

executed.

STBY

(Standby)

From the end of the WAIT

period or the LSTR period

until the input of the pick-up

command from the video

controller. Or, from the end of

the LSTR period until power-

OFF.

To keep the printer ready

to print.

INTR

(Initial rotation)

From the input of the print

command from the video

controller until the pick up

solenoid is turned ON

To stabilize the

photosensiteive drum

sensitivity in preparation

for printing,Also to clean

the transfer charging

roller.

PRINT

(Print)

From the end of the initial

rotation until the primary high-

voltage is turned OFF.

To form image on the

photosensitive drum

according to the video

signals input from the

interface controller, and

transfers the image to

paper.

LSTR

(Last rotation)

From the primary high-voltage

is turned OFF until the main

motor stops rotating.

Delivers the final page and

cleans the transfer

charging roller.

As soon as the print command is

input from the video controller, the

printer enters the INITIAL

ROTATION period.

Summary of Contents for LBP-3000

Page 1: ...H T T P W W W F I X C L U B C O M C N Mar 10 2005 Service Manual LBP3000 2900 Series LBP2900 ...

Page 2: ...H T T P W W W F I X C L U B C O M C N ...

Page 6: ...H T T P W W W F I X C L U B C O M C N ...

Page 12: ...H T T P W W W F I X C L U B C O M C N Contents ...

Page 13: ...H T T P W W W F I X C L U B C O M C N Chapter 1 PRODUCT DESCRIPTION ...

Page 14: ...H T T P W W W F I X C L U B C O M C N ...

Page 16: ...H T T P W W W F I X C L U B C O M C N ...

Page 23: ...H T T P W W W F I X C L U B C O M C N Chapter 2 TECHNICAL REFERENCE ...

Page 24: ...H T T P W W W F I X C L U B C O M C N ...

Page 44: ...H T T P W W W F I X C L U B C O M C N Chapter 2 2 18 ...

Page 51: ...H T T P W W W F I X C L U B C O M C N Chapter 3 DISASSEMBLY AND ASSEMBLY ...

Page 52: ...H T T P W W W F I X C L U B C O M C N ...

Page 87: ...H T T P W W W F I X C L U B C O M C N Chapter 3 3 33 F 3 161 ...

Page 88: ...H T T P W W W F I X C L U B C O M C N ...

Page 89: ...H T T P W W W F I X C L U B C O M C N Chapter 4 MAINTENANCE AND INSPECTION ...

Page 90: ...H T T P W W W F I X C L U B C O M C N ...

Page 92: ...H T T P W W W F I X C L U B C O M C N ...

Page 98: ...H T T P W W W F I X C L U B C O M C N ...

Page 99: ...H T T P W W W F I X C L U B C O M C N Chapter 5 TROUBLESHOOTING ...

Page 100: ...H T T P W W W F I X C L U B C O M C N ...

Page 102: ...H T T P W W W F I X C L U B C O M C N ...

Page 107: ...H T T P W W W F I X C L U B C O M C N Chapter 6 APPENDIX ...

Page 108: ...H T T P W W W F I X C L U B C O M C N ...

Page 110: ...H T T P W W W F I X C L U B C O M C N ...

Page 117: ...H T T P W W W F I X C L U B C O M C N Mar 10 2005 ...