Chapter 2

2-4

4) The scanner mirror reflects the laser beam while rotating at a specific speed so that the beam scans the surface of the photosensitive drum at a corresponding speed.

5) When the photosensitive drum rotates at a specific speed and, in addition, the laser beam scans the surface of the photosensitive drum at a corresponding speed,

a latent image appears on the drum surface.

Note

1. Only one /BDI signal is generated to a scanner motor in this machine.

The /BDI signal to the scanner motor for M/C is generated by the reflection light from M laser, while the BDI signal to the scanner motor for Y/Bk is generated by

the reflection light from Y laser. Based on the /BDI signal, the DC controller PCB generates BD signals for four colors and send them to the video controller

PCB.

2. The machine uses a mechanism in which a single scanner mirror is used for 2 colors; in other words, the direction of scanning differs between colors. (In respect

of the printed side of a print, M/Y starts at the right edge, while C/Bk starts at the left edge.)

2.3.2 Laser Control

2.3.2.1 Outline

0010-6046

LBP5000 / LBP5100

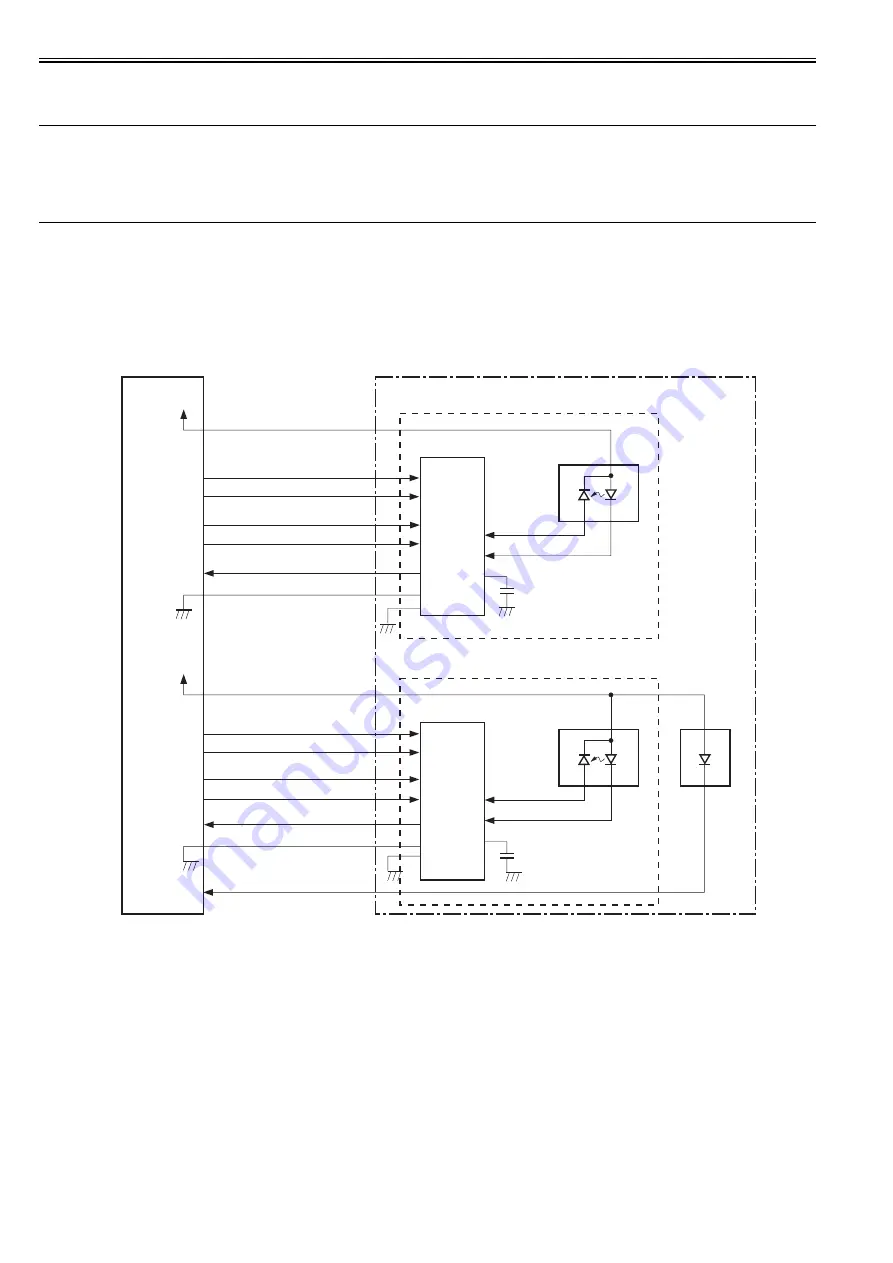

The machine's laser control consists in turning on and off the laser diode by the laser driver according to the laser control signal from the DC controller.

The machine's laser drive PCB is either for M/C or for Y/Bk; both PCBs are identical, and here, the descriptions are of the control mechanism associated with M/C.

F-2-5

The DC controller sends video signals (VDO, /VDO, used to form images) and laser control signals (LDCTRL0, LDCTRL1, used to switch the operating mode of

the laser driver circuit) to individual laser driver ICs, which control the laser activation based on the combination of laser control signals.

The machine controls its laser activation in the following 4 modes as dictated by the laser control signals:

1. laser activation control (turns on or off the laser diode according to the video signal)

2. auto photo current control (APC; makes sure that the intensity of the laser diode is at a specific level)

3. horizontal sync control (makes sure that the laser write start point in image horizontal direction is correct)

4. image mask control (makes sure that the laser beam will not be turned on in the non-image area outside the unblocking period)

The laser current output signal (PDOUT) is an analog signal that is the result of conversion of laser light into a corresponding level of current. The DC controller

PCB sends the respective intensity information to the video controller, representing individual colors (laser beams), obtained from the PDOUT signal so that the

video controller PCB may execute PWM adjustment to suit the selected gradation.

2.3.2.2 Laser Emission Control

0011-1370

LBP5000 / LBP5100

The machine turns on and off the laser diode (LD) according to video signals.

When the DC controller PCB switches the operating mode of the laser driver circuit to print mode, the machine turns on and off the laser diode (LD) at a specific

intensity as dictated by the video signal (VDO, /VDO) coming from the video control.

DC controller PCB

Laser

driver

IC

VDO1

/VDO1

C107

J401A

-3

-3

-10

-9

-12

-11

-10

-9

-12

-11

LD

PD

BD

circuit

PD

LD

IC101

PDOUT1

/BDI12

Laser driver PCB

-13

-13

-15

-15

Magenta laser driver circuit

LD101

Laser

driver

IC

C115

LD

PD

PD

LD

IC102

Cyan laser driver circuit

LD102

VDO2

/VDO2

J401A

-1

-1

-5

-4

-7

-6

-5

-4

-7

-6

PDOUT2

-14

-14

GND

-2

-2

LDCTRL20

LDCTRL21

LDCTRL10

LDCTRL11

GND

-8

-8

+5V

J112

+5V

J112

Summary of Contents for LBP5000 Series

Page 1: ...Feb 26 2007 Service Manual LBP5000 5100 Series...

Page 2: ......

Page 6: ......

Page 14: ...Contents...

Page 15: ...Chapter 1 PRODUCT DESCRIPTION...

Page 16: ......

Page 18: ......

Page 28: ......

Page 29: ...Chapter 2 TECHNICAL REFERENCE...

Page 30: ......

Page 33: ...Contents 2 8 3 2 Overview of the Block 2 39...

Page 34: ......

Page 74: ...Chapter 2 2 40 IC12 Logic IC Converts voltage levels Notation Name Description...

Page 75: ...Chapter 3 DISASSEMBLY AND ASSEMBLY...

Page 76: ......

Page 80: ......

Page 122: ......

Page 123: ...Chapter 4 MAINTENANCE AND INSPECTION...

Page 124: ......

Page 126: ......

Page 132: ......

Page 133: ...Chapter 5 TROUBLESHOOTING...

Page 134: ......

Page 136: ......

Page 141: ...Chapter 5 5 5 F 5 9...

Page 142: ...Chapter 5 5 6 F 5 10...

Page 149: ...Chapter 6 APPENDIX...

Page 150: ......

Page 152: ......

Page 161: ...Feb 26 2007...

Page 162: ......