2

2

2-20

2-20

Technical Overview > Image Formation System > Toner Cartridge > Operation when toner level is Low/Nearly Out

Technical Overview > Image Formation System > Toner Cartridge > Operation when toner level is Low/Nearly Out

Toner Cartridge

■

Toner Level Detection

●

MF4580dn/MF4570dn/MF4550d/MF4553d/MF4554d/MF4450/

MF4452/MF4453

Toner level is detected by the Toner Sensor (Magnetic Sensor). When a Toner Cartridge is

installed, the Toner Sensor contacts with the lower side of the cartridge and it converts the

magnetic changes in the cartridge into voltage.

Then, MPU of DCNT PCB compares the output voltage of the Toner Sensor with the

reference value to detect the toner level.

Toner level detection is performed at startup of the Main Motor.

The toner level detection sequence starts after the Main Motor is started up and stabilization

time (200msec) has passed. The toner level detection sequence continues until the Main

Motor stops. There are following 2 types of toner level detection sequence: sequence at

warm-up rotation when opening door or turning ON the power, and sequence at normal

rotation.

1)Sequence at normal rotation

From the start of detection, detection value of magnetic toner is sampled for every 5 msec.

Remaining toner level is judged based on the average value and ripple value (V Peak to

Peak) of the Magnetic Sensor output while the Stirring Stick makes a full turn.

Time the Stirring Stick makes a full turn and number of samples

In case the process speed is 150mm/sec, time is 1.9 sec (380 samples).

In case the process speed is 75mm/sec, time is 3.8 sec (760 samples).

2)Sequence at warm-up rotation

Conditions of sampling and remaining toner level judgment are the same as those

mentioned above.

However, in the case that toner Low is detected even at once during warm-up rotation

sequence, toner Low is remained to be displayed.

●

D550/D520/MF4430/MF4420n/MF4410/MF4412

This equipment has no function of toner level detection.

■

Specification of Toner level display

Toner level can be checked by pressing Status Monitor/Cancel key and selecting toner level.

Display patters are as follow: OK, Low, and Nearly Out. See the table below for the display

pattern.

1)OK: Toner level** status is 10% or higher and 100% or less, or toner level unidentified**

status

2)Low: Toner level** status is 5% or higher and less than 10%.

3)Nearly Out: Toner level** status is less than 5%.

* Toner level unidentified: Status until the engine determines the toner level.

** Toner level: Reference value (%) (which varies depending on the stirring condition of toner)

is displayed.

As for the toner stop processing according to job types, follow the list of stop processing

according to toner level.

In the following cases, status of toner level is considered as unidentified, and OK (100%) is

displayed on the panel.

• After power-on

• Right after recovery from engine sleep mode

• During opening/closing the door

• When the cartridge is not installed

■

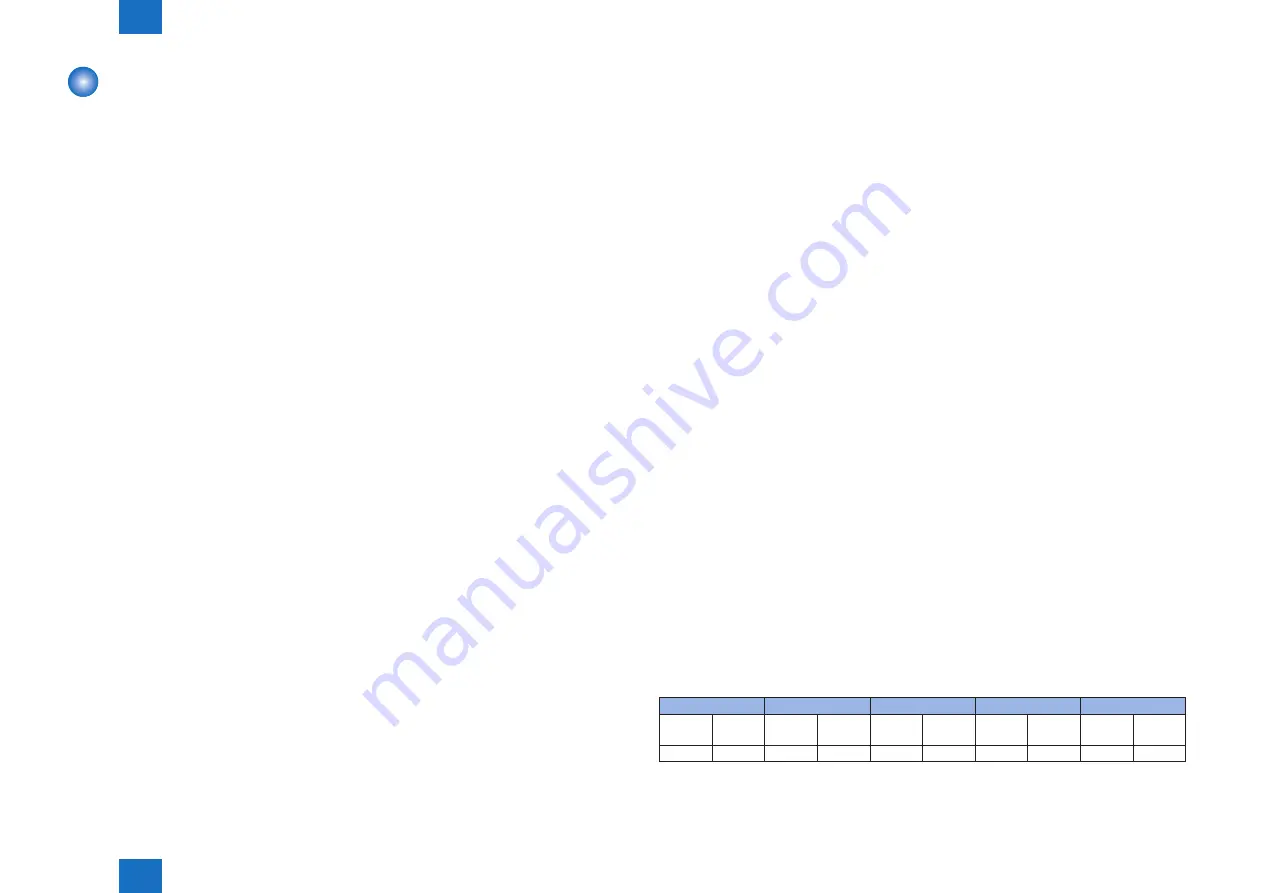

Operation when toner level is Low/Nearly Out

Operation when toner level is Low or Nearly Out is as follow. If another job which can be

processed is introduced while there is a job which is stopped due to "Nearly Out", the job is

output by overtaking the preceding job.

List of stop processing according to toner level

Copy

PDL

Receive print

Manual report

Auto report

Low

Nearly

Out

Low

Nearly

Out

Low

Nearly

Out

Low

Nearly

Out

Low

Nearly

Out

○

○

○

○

○

-

○

○

○

-

○: Continues

-: Page output is stopped immediately after detection, but it can be continued by user mode.

T-2-4

Summary of Contents for MF4500 Series

Page 222: ...5 5 Adjustment Adjustment Mechanical Adjustment ...

Page 224: ...6 6 Trouble Shooting Trouble Shooting Test Print Trouble Shooting Items Version Upgrade ...

Page 230: ...7 7 Error Codes Error Codes Overview Error Codes ...

Page 234: ...8 8 Service Mode Service Mode Overview COPIER FEEDER FAX TESTMODE ...

Page 251: ... Service Tools Solvent Oil List General Circuit Diagram General Timing Chart Appendix ...