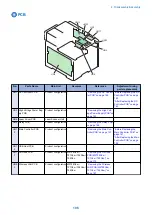

4. Install the Left Cover [1].

• 1 Claw [2]

• 8 Hooks [3]

• 2 Screws [4]

[4]

[2]

[1]

[3]

[3]

2x

1x

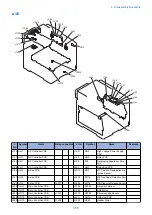

Removing the Right Cover

■ Procedure

1. Open the ADF Unit + Reader Unit [1], and remove the

Right Cover [2].

• 4 Screws [3]

• 3 Hooks [4]

[3]

[4]

[3]

[3]

[2]

[1]

4x

■ Installing the Right Cover

1. Fit the 3 hooks [2] of the Right Cover into the holes

[3] of the Upper Cover.

[2]

[1]

3x

[3]

[2]

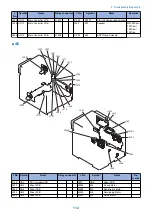

2. While pushing the Right Cover [1] to the Host

Machine, fit the left surface [A] of the Right Cover to

the right surface [B] of the Right Front Cover.

[1]

[B]

[A]

4. Disassembly/Assembly

120

Summary of Contents for MF720 Series

Page 1: ...Revision 2 0 MF720 Series Service Manual...

Page 12: ...Product Overview 1 Product Lineups 5 Product Features 7 Specifications 8 Name of Parts 14...

Page 79: ...4 Click Import Export Import 1 2 2 Technical Explanation 71...

Page 103: ...Durable Parts No durable parts is set for this product 3 Periodical Service 95...

Page 104: ...Periodical Services No periodical service is set for this product 3 Periodical Service 96...

Page 232: ...Adjustment 5 Overview 225 Adjustment at Parts Replacement 226...

Page 248: ...Troubleshooting 6 Test Print 241 Trouble shooting items 243 Version Upgrade 244 Debug Log 248...

Page 258: ...Error Jam Alarm 7 Outline 251 Error Codes 252 Jam Code 257...

Page 267: ...Service Mode 8 Overview 260 COPIER 264 FEEDER 300 FAX 302 TESTMODE 308...

Page 322: ...APPENDICES Service Tools 315 General Circuit Diagram 316 Print Sequence 317 Backup Data 318...