(26/34)

< How to reset the ink absorber counter >

Set the specified value to the applicable ink absorber counter after Regular Replacement.

Start the machine in the service mode, and set the value in the

Ink Absorber Counter

section of the

Service Tool. (See 2-1, Service Mode, for details.)

- Main_Black:

0%

- Main_Color:

0%

3-3. Preventive Replacement of Ink Absorber

Replace the ink absorber in accordance with the "

Guideline for Preventive Replacement of Ink Absorber

"

even when the ink absorber is not full. (Related Service Information #Q-12E/J-0188)

< Guideline for Preventive Replacement of Ink Absorber >

Replace the ink absorber when it falls in either Criteria 1 or Criteria 2.

Criteria

Purpose

How to know the criteria values

Criteria 1:

The ink absorber life* is 2

years or less.

To avoid re-repair for ink absorber

replacement in a short period of

time after repair for other reasons.

For 2009 2H or earlier products:

EEPROM information print and the

quick reference table (refer to

Service Information #Q-12E/J-0188

for details).

For 2010 1H and later products:

EEPROM information print

Criteria 2:

The ink absorber counter

value is 80% or more.

To prevent ink leakage during return

of the repaired machine to users.

EEPROM information print

*

The estimated number of months until the ink absorber will become full

< How to judge >

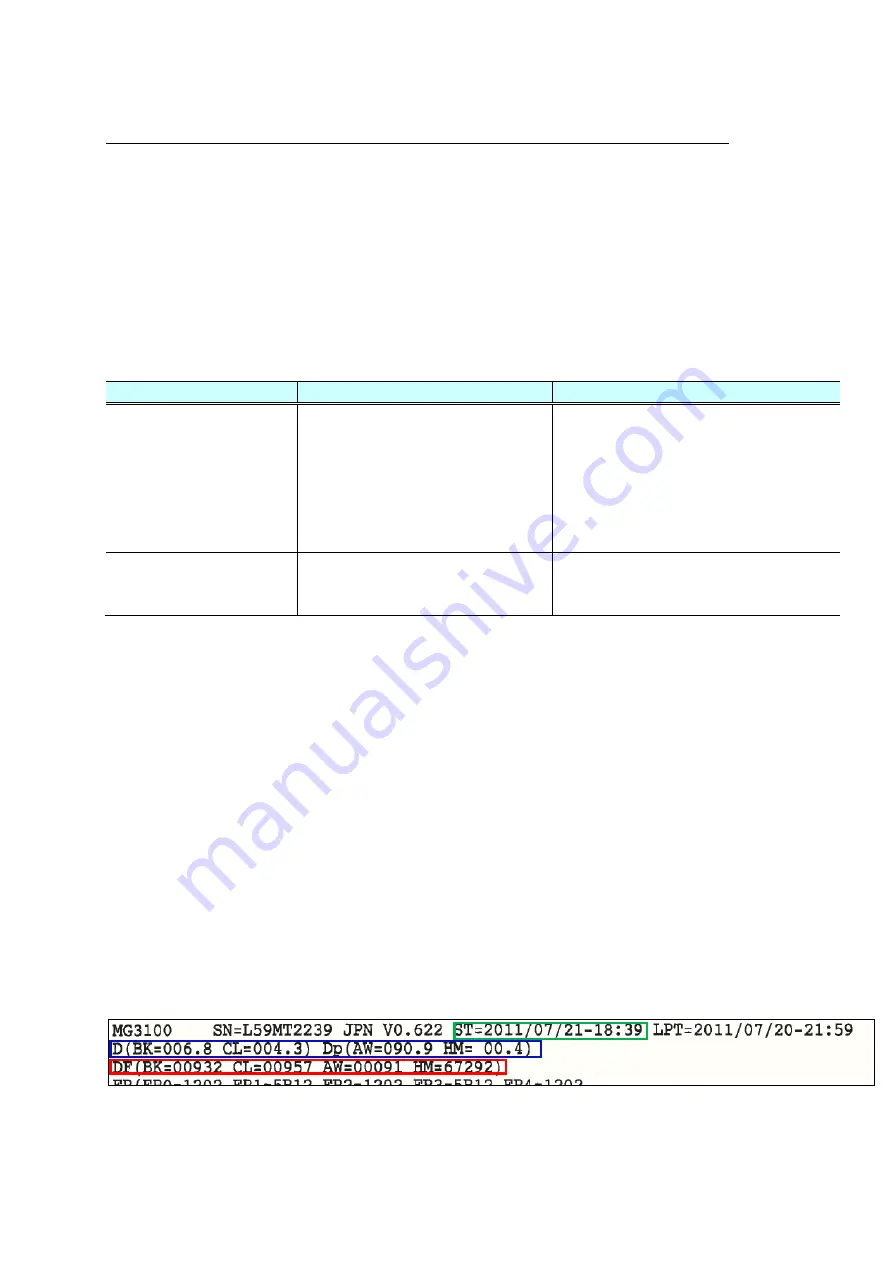

Print the EEPROM information, and check the "D" and “Dp” (ink absorber counter) and "DF" (ink absorber

life) values.

Step 1:

Is "D" or “Dp” 80% or more?

Yes (80% or more) ->

Replace the ink absorber.

No (less than 80%) ->

Proceed to Step 2.

Step 2:

Is "DF" 24 or more?

No (less than 24 months) -> Replace the ink absorber.

Yes (24 months or more) -> No need to replace the ink absorber.

Note: If the "ST" (installation date) value is 2011/07/31 earlier, the "DF" (ink absorber life) value

is incorrect. Skip Step 2.

The ink absorber life is an estimated value calculated based on the user's machine

usage.

< How to read the EEPROM information print >

Installation date

Ink absorber counter value (%)

Ink absorber life (months)

0

easyfixs.blogspot.com