2–9

STANDARDS AND ADJUSTMENTS

a. Measuring the Nip

Measure the nip when the machine is turned on

for the first time in the morning.

1) Open the copyboard cover, and make an A4

(SM0-1) solid black copy.

2) Place the copy in the cassette tray face down

(solid black facing downward).

3) Press the service mode switch (SW850) with a

hex key.

• The machine starts service mode and indi-

cates ‘1’.

4) Press ‘4’ on the numeric keypad.

• The display indicates ‘4’.

5) Press the AE key.

• The machine enters operation/inspection

mode and indicates ‘401’.

6) Press ‘6’ on the numeric keypad.

• The display indicates ‘406’.

7) Press the Start key.

• The paper will be fed from the cassette, and

the machine will be ready to accept new

settings as in Figure 2-223. (The paper will be

discharged.)

Reference:

The paper stops while half of it is held between

the fixing rollers; it will then be discharged fully

about 10 sec later.

8) Measure the nip.

16

Points to Note After Replacing

the Upper Fixing Unit

If you replaced the upper fixing unit, you must

enter the temperature offset value of the heater

using service mode No. 304. (See p. 7-10)

17

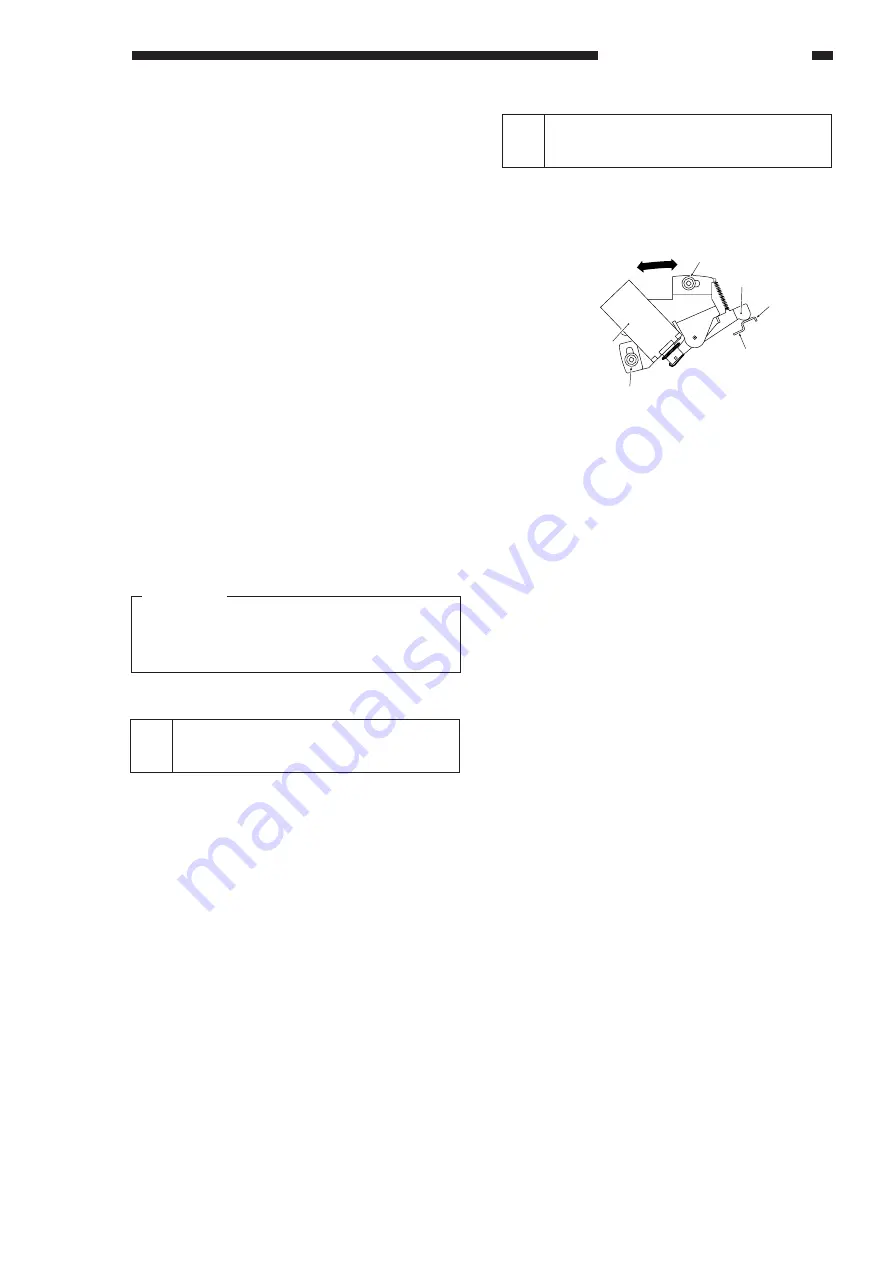

Mounting the Oil Application

Solenoid

Screw the oil application solenoid in place where

its lever is lightly in contact with the support of the oil

application roller.

Figure 2-224

Oil application

Solenoid

Screw

Screw

Lever

Contact

Support

Summary of Contents for NP6621

Page 4: ...ii ...

Page 8: ...vi ...

Page 48: ...3 2 IMAGE FAULTS ...

Page 49: ...3 3 IMAGE FAULTS NOT USED ...

Page 50: ...3 4 IMAGE FAULTS B Image Fault Samples not available ...

Page 80: ...4 16 TROUBLESHOOTING MALFUNCTIONS ...

Page 134: ...A 4 APPENDIX ...

Page 135: ...A 5 APPENDIX C GENERAL CIRCUIT DIAGRAM not available ...

Page 136: ...A 6 APPENDIX ...

Page 144: ...A 14 APPENDIX ...