CHAPTER 3 EXPOSURE SYSTEM

COPYRIGHT © 1999 CANON INC. CANON PC800s/900s REV.0 AUG. 1999 PRINTED IN JAPAN (IMPRIME AU JAPON)

3-23

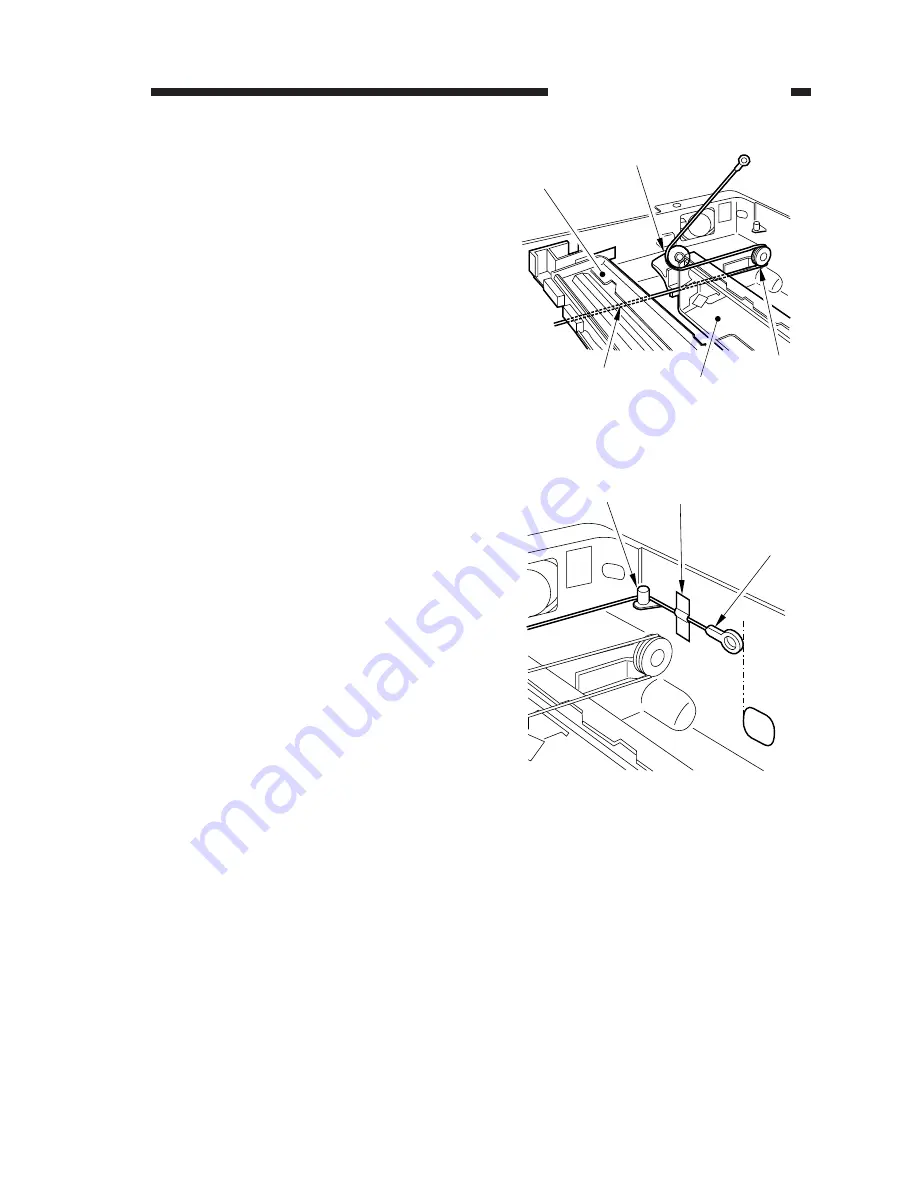

Figure 3-319

Figure 3-320

[8]

[17]

[9]

[16]

[14]

[18]

[19]

[14]

7) Lead the longer end [14] under the No. 1

mirror mount [8] and the No. 2/3 mirror

mount [9]; then, hook it on the pulley [16]

on the left front side and the pulley [17] of

the No. 2/3 mirror mount.

8) Hook the longer end [14] on the cable

hook [18]; then, secure its end to the left

side with adhesive tape [19].

Be sure that the secured end of the cable is

found where the hole in the left side plate

and the tip of the cable matches.

Summary of Contents for PC800 Series

Page 12: ......

Page 34: ......

Page 36: ......

Page 48: ......

Page 50: ......

Page 92: ......

Page 94: ......

Page 122: ......

Page 124: ......

Page 162: ......

Page 164: ......

Page 180: ......

Page 206: ......

Page 240: ......

Page 242: ......

Page 256: ......

Page 263: ......

Page 265: ......

Page 355: ......

Page 383: ......