(6/23)

3. ERROR DISPLAY

Errors are displayed by the LEDs, and ink low warnings are displayed by the Status Monitor.

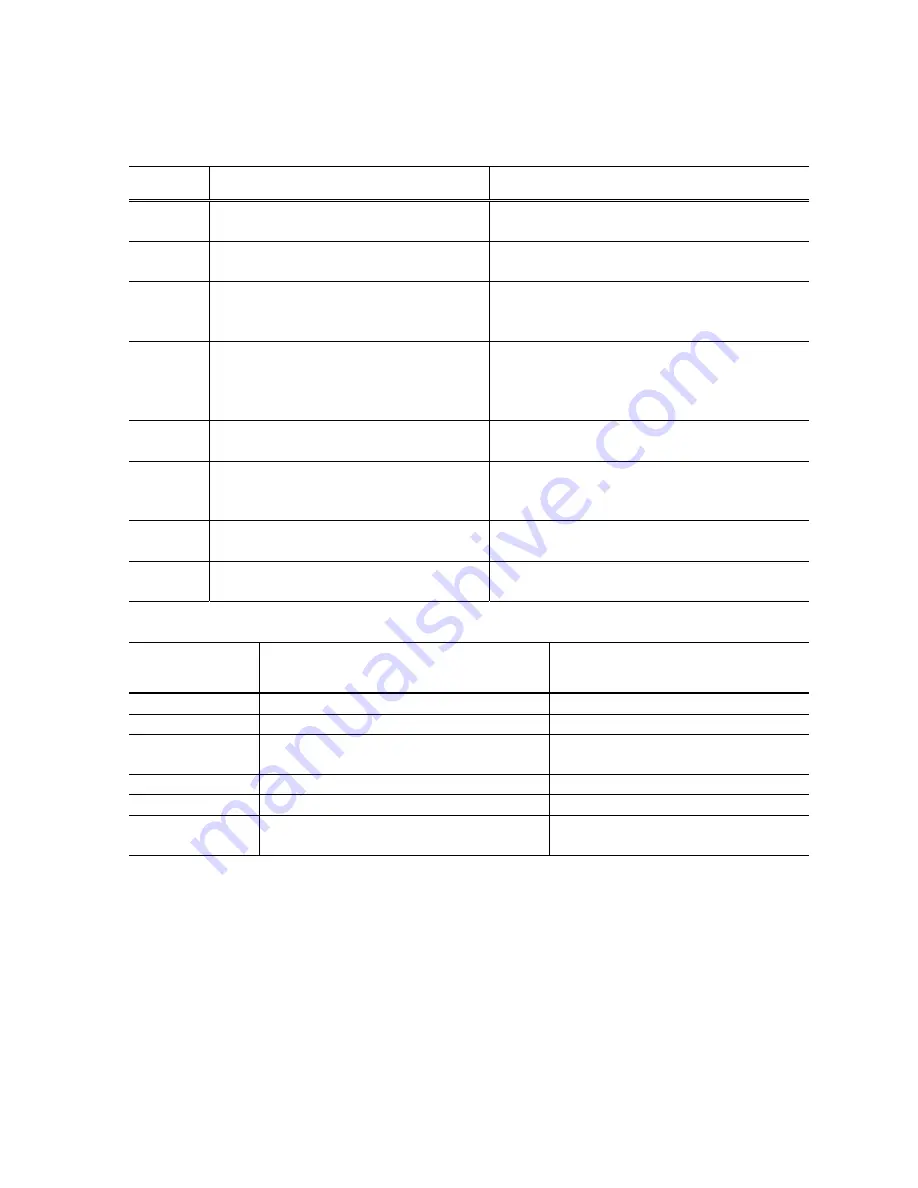

3-1. Operator Call Error (Alarm LED Blinking in Orange)

Alarm LED

blinking

Error Corrective

action

2 times

No paper

Set paper, and press the Resume/Cancel button

to feed the paper.

3 times

Paper jam

Remove the jammed paper, and press the

Resume/Cancel button.

4 times

No ink

Replace the ink cartridge(s), or press the

Resume/Cancel button to continue printing

without replacing the ink cartridge(s).

5 times

The ink cartridges are not properly

installed, or a non-supported ink cartridge

is installed (the ink cartridge EEPROM

data is abnormal).

Install the ink cartridges properly.

Or, confirm that the supported ink cartridges are

installed.

7 times

Ink cartridge not installed

Install the ink cartridge(s), and close the access

cover.

8 times

Waste ink absorber full or platen waste ink

absorber full warning (approx. 95% of the

maximum capacity)

Pressing the Resume/Cancel button will exit the

error, and enable printing.

14 times

Non-supported ink cartridge installed

Replace the non-supported ink cartridge with the

supported one.

16 times

Used ink cartridge installed, or no ink

Pressing the Resume/Cancel button will exit the

error, and enable printing.

3-2. Service Call Error (Cyclic Blinking in Orange (Alarm LED) and Green (Power LED))

Cycles of blinking

in orange and

green

Error Corrective

Action

2 times

Carriage error

Replace the printer as it has failed.

3 times

LF error

Replace the printer as it has failed.

7 times

Waste ink absorber full or platen waste ink

absorber full

Replace the printer as it has failed.

8 times

Print head temperature rise error

Replace the printer as it has failed.

9 times

EEPROM error

Replace the printer as it has failed.

10 times

No ink cartridge detected excepting ink

cartridge replacement (during printing)

Replace the printer as it has failed.

Summary of Contents for Pixma iP1600 Pixma iP1200

Page 16: ...15 23...