<Service mode operation procedures>

1) With the printer power turned off, while pressing the Resume/Cancel button, press and hold the Power button. (DO NOT release the buttons. The LED lights

in green to indicate that a function is selectable.)

2) While holding the Power button, release the Resume/Cancel button. (DO NOT release the Power button.)

3) While holding the Power button, press the Resume/Cancel button 2 times, and then release both the Power and Resume/Cancel buttons. (Each time the

Resume/Cancel button is pressed, the LED lights alternately in orange and green, starting with orange.)

4) When the LED lights in green, press the Resume/Cancel button the specified number of time(s) according to the function listed in the table below. (Each time

the Resume/Cancel button is pressed, the LED lights alternately in orange and green, starting with orange.)

5) After the function (menu) is selected, press the Power button. The LED lights in green, and the selected function is performed. (When the operation

completes, the printer returns to the menu selection mode automatically.)

<Destination settings procedures>

In the destination settings mode, press the Resume/Cancel button the specified number of time(s) according to the destination listed in the table below, and press

the Power button.

Note: After setting the destination, confirm the model name in the service test print or EEPROM information print.

[See 3-4. Verification Items, (1) Service test print,

or (2) EEPROM information print.]

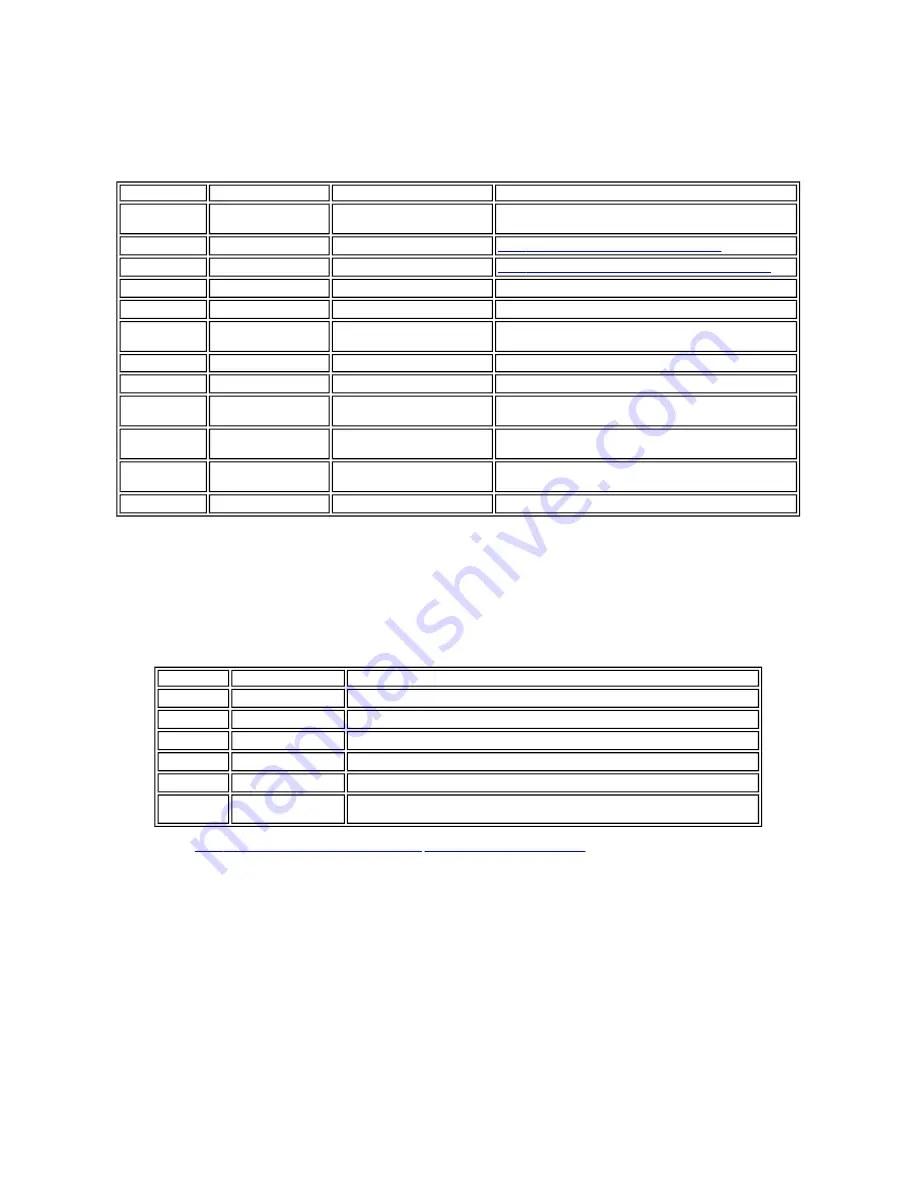

Time(s)

LED

Function

Remarks

0 times

Green

Power off

When the print head is not installed, the carriage returns and

locks in the home position.

1 time

Orange

Service test print

See 3-4. Verification Items, (1) Service test print.

2 times

Green

EEPROM information print

See 3-4. Verification Items, (2) EEPROM information print.

3 times

Orange

EEPROM initialization

4 times

Green

Waste ink counter resetting

5 times

Orange

Destination settings

Proceed to the following step 5), and follow the Destination

settings procedures.

6 times

Green

Print head deep cleaning

7 times

Orange

CD-R test print

Not used in servicing.

8 times

Green

CD-R print position correction

(horizontal)

Not used in servicing.

9 times

Orange

CD-R print position correction

(vertical)

Not used in servicing.

10 times

Green

Button and LCD viewer test

Proceed to the following step 5), and follow the Button and

LCD viewer test

procedures.

11 times or more

Return to the menu selection

Time(s)

LED

Destination

1 time

Orange

Japan: iP6100D

2 times

Green

Other than Japan, non-support of CD-R printing (A4): iP6000D (A4)

3 times

Orange

Other than Japan, non-support of CD-R printing (LTR): iP6000D (LTR)

4 times

Green

Other than Japan, support of CD-R printing (A4): iP6000D (A4)

5 times

Orange

Other than Japan, support of CD-R printing (LTR): iP6000D (LTR)

6 times or

more

Return to the menu selection

1 - 14

Summary of Contents for PIXMA iP6000D

Page 7: ...Part 1 MAINTENANCE ...

Page 17: ... 3 Grease application 1 10 ...

Page 27: ...Part 2 TECHNICAL REFERENCE ...