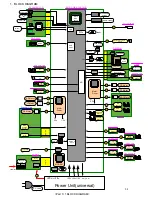

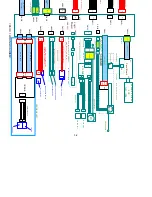

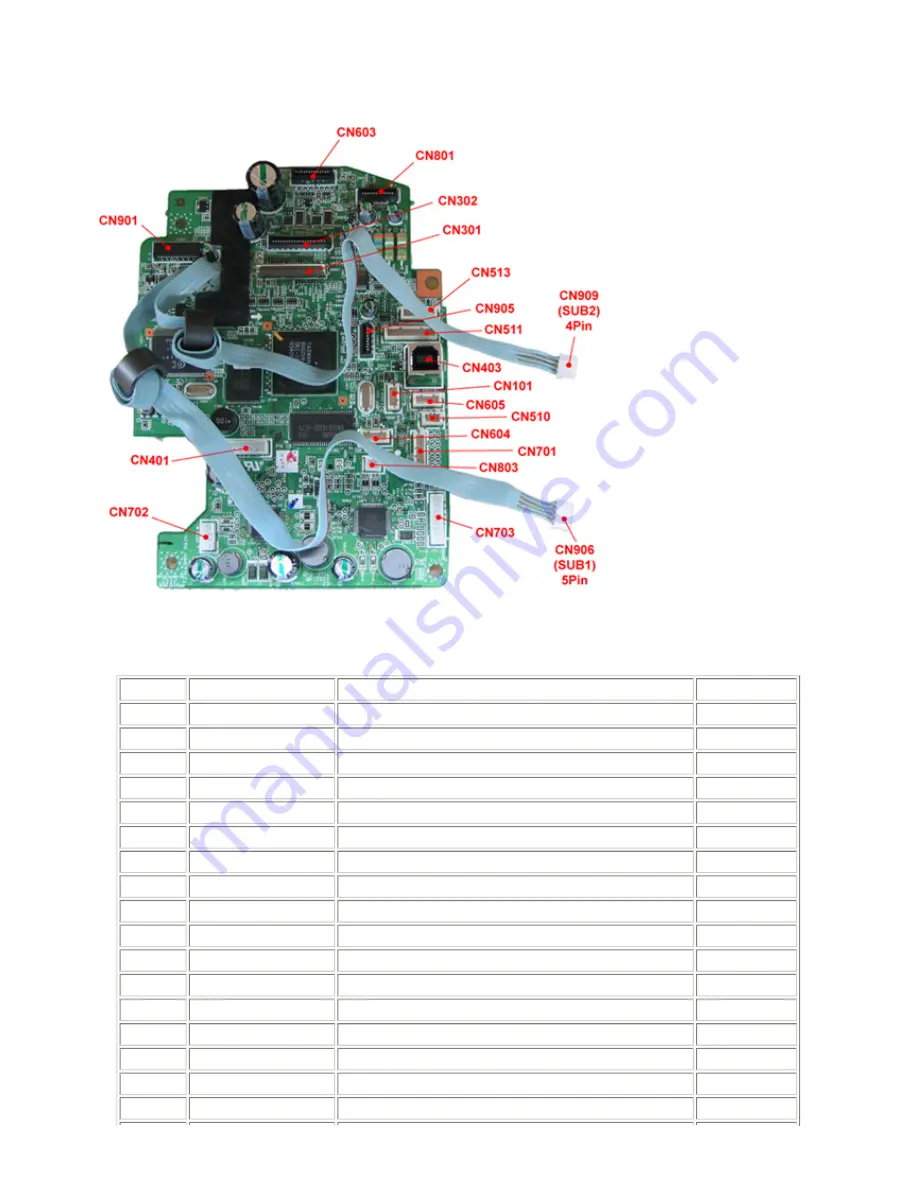

3. CONNECTOR LOCATION AND PIN LAYOUT

3-1. Logic Board Ass'y

CN101 (Not used)

CN301(Print Head 1/2 [Carriage Unit])

No.

Signal name

Function

Input / Output

1

AB_POW

Ink tank sensor chip power supply

OUT

2

AB_DATA

Ink tank sensor data signal

BUS

3

AB_POW

Ink tank sensor chip power supply

OUT

4

AB_CLK

Ink tank sensor data transfer clock signal

BUS

5

LOGIC_GND

Logic ground

-

6

H_D3

Head data (PK2)

OUT

7

H_D0

Head data (BK1)

OUT

8

H_D1

Head data (BK2)

OUT

9

H_D5

Head data (SC1)

OUT

10

H_ENB0

Head heat enable signal 0 (BK)

OUT

11

LOGIC_GND

Logic ground

-

12

DIA0

Diode sensor anode 0

IN

13

LOGIC_GND

Logic ground

-

14

H_D2

Head data (PK1)

OUT

15

H_D4

Head data (C1)

OUT

16

H_ENB3

Head heat enable signal (SCol)

OUT

17

H_D8

Head data (Y1)

OUT

3-3

Summary of Contents for PIXMA MP530

Page 5: ...Part 1 MAINTENANCE ...

Page 34: ... Right side c Disconnect the connector for the solenoid 1 29 ...

Page 51: ... Service test print sample 1 46 ...

Page 56: ... System data list sample 1 51 ...

Page 57: ... Error transmission report sample 1 52 ...

Page 60: ...Part 2 TECHNICAL REFERENCE ...

Page 73: ...Part 3 APPENDIX ...