INTRODUCTION

[ How to use this Service Manual ]

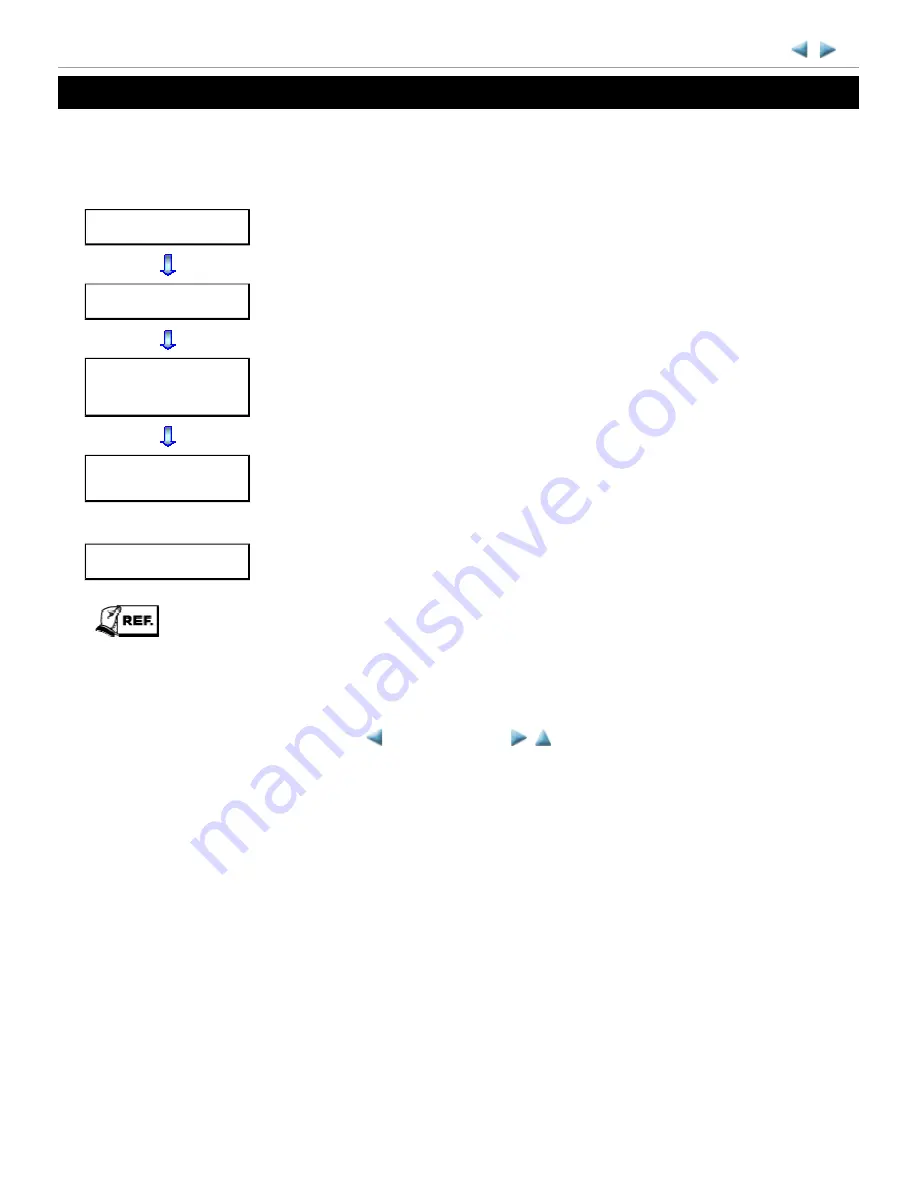

This manual is intended to solve printer problems smoothly, with each section representing the typical service

procedures, as shown below.

This manual does not provide sufficient information for disassembly and reassembly procedures. Refer to the

graphics in the separate Parts Catalog.

MX880 series

Troubleshooting

Identify the problem, and handle it accordingly.

Repair

When a part needs to be replaced, see this section.

Adjustment &

Settings

After repair, perform the necessary adjustment and settings.

Verification

At the end of the servicing, verify the machine following the inspection flow in this

section.

Appendix

Information that will be necessary for maintenance and repair of the machine

<INTRODUCTION>

Summary of Contents for PIXMA MX882 Series

Page 32: ...8 Remove the main case no screws 28 76...

Page 35: ...4 Remove the LCD ass y no screws 31 76...

Page 55: ...2 Service Tool functions Service Tool screen Version 2 000 51 76...

Page 56: ...52 76...

Page 67: ...63 76...

Page 74: ...4 2 Integrated Inspection Pattern Print Print sample...

Page 75: ...4 3 Ink Absorber Counter Value Print Print sample 4 VERIFICATION AFTER REPAIR...

Page 78: ......