Chapter 5

5-11

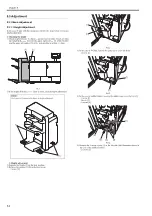

5.3.2.6 Adjusting Position of Feed Belt

0021-1711

Execute this adjustment when replacing the feed belt of the intermediate

process tray or EEPROM on the finisher controller PCB, or in the case of

variation in delivery stack.

Adjusting method is as follows:

1) Turn ON the power of the finisher.

2) Turn ON the power switch of the host machine to be on standby.

3) Open the front cover and put the door switch tool into the door switch [1].

F-5-42

4) Remove the screw [2] to remove the switch cover [1].

F-5-43

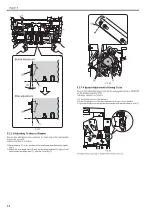

5) Set DIP SW382 [1] on the switch PCB as shown in the figure below.

F-5-44

6) Press switch SW385 [1] to start position adjustment of the feed belt.

F-5-45

7) Pressing switch SW383 [1] or SW384 [2] determines adjustment level.

By pressing SW383 once, the LED [3] indicates "-1" and the distance

between the belt [4] and the sheet interval [5] is reduced to increase

feeding force of the belt. In the same way, by pressing SW384 once, the

LED indicates "+1" and the distance between the belt [4] and the sheet

interval [5] increased to reduce feeding force of the belt. (Adjustment

range: +4 to -4).

[1]

[2]

[1]

MEMO:

1. Increase feeding force by setting adjustment value to negative value (-1

to -4) in the case of wear of the feed belt or using recycled paper (paper with

large surface resistance).

2. Reduce feeding force by setting adjustment value to positive value (+1 to

+4) in the case that dent on the paper edge is shown.

SW382

SW381

SW383

(-)

(+)

ENTER

SW384 SW385

DSP381

[1]

SW382

SW381

SW383

(-)

(+)

ENTER

SW384 SW385

DSP381

[1]

Summary of Contents for Saddle Finisher-AF2

Page 1: ...SERVICE MANUAL Saddle Finisher AF2 MARCH 6 2009...

Page 2: ......

Page 6: ......

Page 12: ...Contents...

Page 13: ...Chapter 1 Specifications...

Page 14: ......

Page 16: ......

Page 22: ......

Page 23: ...Chapter 2 Installation...

Page 24: ......

Page 26: ......

Page 55: ...Chapter 3 Functions...

Page 56: ......

Page 58: ......

Page 104: ...Chapter 3 3 46...

Page 105: ...Chapter 4 Parts Replacement Procedure...

Page 106: ......

Page 110: ......

Page 157: ...Chapter 4 4 47 F 4 213 3 2 1...

Page 158: ......

Page 159: ...Chapter 5 Maintenance...

Page 160: ......

Page 209: ...Chapter 5 5 47 F 5 221 SW382 SW381 SW383 ENTER SW384 SW385 DSP381 1...

Page 218: ......

Page 219: ...Appendix...

Page 220: ......

Page 221: ...General Timing Chart General Circuit Diagram Finisher Sorter DeliveryTray Saddle Finisher AF2...

Page 222: ......

Page 224: ......

Page 225: ...Contents 1 General Circuit Diagram 1 Signal Names 1 General Circuit Diagram 9...

Page 226: ......

Page 243: ......

Page 244: ......