If there is not the output of the "P-PRINT"

1. Set the SW1 keys as shown below and press the SW2.

ON

1

2

3

4

SW1

SW2

2. Set all SW1 keys set to OFF.

ON

1

2

3

4

SW1

SW2

3. Enter the values written to the service label affixed to the

front cover.

Removing the Saddle Stitcher

Controller PCB (PCB201)

■ Preparation

1. Pull out the saddle unit.

“ Pulling Out the Saddle Unit (Service Position)” on page

131

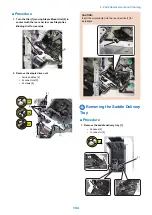

■ Procedure

1. Remove the PCB cover.

• 2 screws [2]

2x

[2]

[1]

2. Remove the PCB [1].

• 10 connectors [2]

• 2 screws [3]

• 2 PCB retainers [4]

2x

10x

[1]

[3]

[3]

[2]

[2]

[2]

[4]

[4]

Removing the Buffer Pass

Controller PCB (PCB201)

■ Preparation

1. Remove the Buffer Pass Unit.

“Removing the Buffer Pass Unit” on page 78

■ Procedure

1. Remove the Buffer Pass Controller PCB [1].

• 1 Screw [2]

• 9 Connectors [3]

4. Parts Replacement and Cleaning

118

Summary of Contents for Staple Finisher-AA1

Page 1: ...Revision 4 0 Staple Finisher AA1 Booklet Finisher AA1 Service Manual ...

Page 12: ...Product Overview 1 Features 5 Specifications 6 Names of Parts 14 Optional Configuration 20 ...

Page 83: ...Periodical Service 3 Periodic Servicing Tasks 76 ...

Page 87: ...3 Remove the 2 Connectors 1 2x 1 4 Parts Replacement and Cleaning 79 ...

Page 89: ...Main Units Parts 4 5 6 7 8 1 2 3 4 Parts Replacement and Cleaning 81 ...

Page 128: ...4x 1 2 2 3 3 2x 4 Parts Replacement and Cleaning 120 ...

Page 150: ...Adjustment 5 Overview 143 Basic Adjustment 148 Adjustments When Replacing Parts 173 Other 184 ...

Page 193: ...Troubleshooting 6 Making Initial Checks 186 Processing Tray Area 187 Saddle Stitcher Area 188 ...

Page 204: ...4 5 6 7 8 9 7 Installation 196 ...

Page 205: ...10 7 Installation 197 ...

Page 223: ...2 3 2x 7 Installation 215 ...

Page 224: ...APPENDICES Service Tools 217 General Circuit Diagram 218 ...