Items

Service Mode

(SORTER > OP-

TION)

Use case

Remarks

Setting whether to limit the stack ca-

pacity of the stapled or folded

sheets

TRY-STP

When stacking papers beyond the maxi-

mum number of stapled copies/folded

sheets.

When the stacking limit is

cleared, stacking capacity in-

creases, but stacking perform-

ance decreases.

Setting whether to limit the stack ca-

pacity of the stack tray

TRY-LMT

When the stacking performance decreases

by the curled paper during stacking a large

amount of the small size paper except the

thin paper and coated paper.

Switching the high-productivity

punch mode or high-accuracy

punch mode of the puncher unit

PUCH-SW

When switching the high-productivity punch

mode or high-accuracy punch mode.

- The settings of this mode and

the "Settings/Registration"

change at the same time.

- This mode is available when

the puncher unit has been in-

stalled.

Setting whether to perform the hor-

izontal registration operation of the

puncher unit for matching with the

center of the paper

PUN-Y-SW

When the adjustable range of the punch

hole horizontal registration adjustment

(PNCH-Y) is enlarged.

This mode is available when

the puncher unit has been in-

stalled.

Setting the punch hole specification

of the puncher unit

PNCH-SW2

When replacing the puncher unit.

This mode is available when

the puncher unit has been in-

stalled.

Setting ON/OFF of the mode to im-

prove the precision of the punch

hole position

PNCH-SW3

When the position of the punch hole is mis-

aligned.

- When setting to ON, the pro-

ductivity is decreased.

- When setting the punch mode

to the precision priority, this

mode enables.

- This mode is available when

the puncher unit has been in-

stalled.

Basic Adjustment Items

No

Items

Use case

Refer to

1

Adjusting the Paper

Alignment

Adjusting Stacker Alignment Position

When misalignment occurs in front/rear di-

rection.

“Adjusting Stacker Align-

ment Position” on page

149

2

Adjusting Center Alignment Standard

Position

• When the standard position for the

center alignment is misaligned.

• When misalignment occurs in front/

rear direction.

“Adjusting Center Align-

ment Standard Position ”

on page 150

3

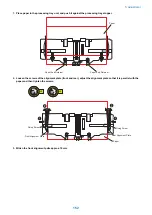

Right Angle Adjustment of Alignment

Plate

• When remove or replace the align-

ment plate.

• When the paper alignment position is

displaced.

“Right Angle Adjustment

of Alignment Plate ” on

page 151

4

Adjusting Delivery of Staple Stack

When the paper displacement occurs on

the 1st to 2nd sheets of buffered paper.

“Adjusting Delivery of

Staple Stack ” on page

154

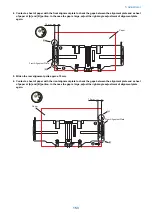

5

Adjusting the Return Roller/Swing Unit

Height

• When misalignment occurs in feed di-

rection.

• When misalignment occurs by failure

of the paper feeding to processing

tray.

“Adjusting the Return

Roller/Swing Unit Height ”

on page 155

6

Adjusting the Sta-

ple Position

Adjusting the Staple Position

When the staple position in front/rear di-

rection is displaced in the front/rear 1-sta-

pling mode or 2-stapling mode.

“Adjusting the Staple Po-

sition ” on page 158

7

Adjusting the Stapler Unit Installation

Position

• When the stapler unit is replaced.

• When the staple position in feed di-

rection is displaced in the front/rear 1-

stapling mode or 2-stapling mode.

“Adjusting the Stapler

Unit Installation Position ”

on page 159

5. Adjustment

146

Summary of Contents for Staple Finisher-AA1

Page 1: ...Revision 4 0 Staple Finisher AA1 Booklet Finisher AA1 Service Manual ...

Page 12: ...Product Overview 1 Features 5 Specifications 6 Names of Parts 14 Optional Configuration 20 ...

Page 83: ...Periodical Service 3 Periodic Servicing Tasks 76 ...

Page 87: ...3 Remove the 2 Connectors 1 2x 1 4 Parts Replacement and Cleaning 79 ...

Page 89: ...Main Units Parts 4 5 6 7 8 1 2 3 4 Parts Replacement and Cleaning 81 ...

Page 128: ...4x 1 2 2 3 3 2x 4 Parts Replacement and Cleaning 120 ...

Page 150: ...Adjustment 5 Overview 143 Basic Adjustment 148 Adjustments When Replacing Parts 173 Other 184 ...

Page 193: ...Troubleshooting 6 Making Initial Checks 186 Processing Tray Area 187 Saddle Stitcher Area 188 ...

Page 204: ...4 5 6 7 8 9 7 Installation 196 ...

Page 205: ...10 7 Installation 197 ...

Page 223: ...2 3 2x 7 Installation 215 ...

Page 224: ...APPENDICES Service Tools 217 General Circuit Diagram 218 ...