No

Items

Use case

Refer to

8

Adjusting the Sta-

ple Position

Adjusting the Staple-Free Binding Po-

sition

When the staple-free binding position in

the staple-free binding mode.

“Adjusting the Staple-

Free Binding Position ” on

page 161

9

Adjusting the Fold

Position

Adjusting the Saddle Paper End Stop-

per Installation Angle

If the fold position of the paper stack deliv-

ered from the saddle stitcher unit is

skewed.

“Adjusting the Saddle Pa-

per End Stopper Installa-

tion Angle” on page 162

10

Adjusting the Fold Placement

When misalignment occurs in feed direc-

tion.

“Adjusting the Fold Place-

ment ” on page 164

11

Adjusting the Saddle Alignment Plate

Position

When misalignment occurs in front/rear di-

rection.

“Adjusting the Saddle

Alignment Plate Position ”

on page 165

12

Adjusting the Sad-

dle Stitch

Adjusting the Stitcher Unit Installation

Position

• When the stitch positions of the front

and rear sides become misaligned

• If you remove or replace the stitcher

unit

“Adjusting the Stitcher

Unit Installation Position ”

on page 167

13

Adjusting the Saddle Stitch Position

When the saddle stitch position in the sad-

dle stitch mode.

“Adjusting the Saddle

Stitch Position ” on page

171

Adjustments When Replacing Parts Items

No

Target part

Adjustment item and description

Refer to

1

Stack Tray Drive Belt

Align the phase of the belt installation position.

“Phase Alignment When Installing the

Stack Tray Drive Belt” on page 173

2

Swing Unit

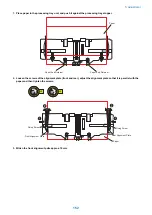

Align the phase of the swing unit installation position, and fix them

in place.

“Phase Alignment When Installing the

Swing Unit” on page 173

3

Paddle Unit

Align the phase of the paddle unit installation position.

“Phase adjustment of paddle unit” on

page 174

4

Stapler Unit

Adjust the staple position

5

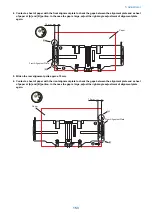

Paper Folding Roller

Align the phase of the paper folding roller installation position.

“Phase Alignment When Installing the

Paper Folding Roller” on page 179

6

Stitcher Unit

Adjust the stitcher unit and the stitch positions.

7

Finisher Controller PCB

Backup operation before replacement and operation after re-

placement

“ Handling Finisher Controller PCB

Replacements” on page 180

Other

No

Items

Use case

Refer to

1

Releasing the Saddle Delivery Tray Stacking

Limit

This is performed when you want to contin-

uously stack over the allowable stacking ca-

pacity when stacking in the saddle delivery

tray.

“Releasing the Saddle Delivery

Tray Stacking Limit” on page 184

5. Adjustment

147

Summary of Contents for Staple Finisher-AA1

Page 1: ...Revision 4 0 Staple Finisher AA1 Booklet Finisher AA1 Service Manual ...

Page 12: ...Product Overview 1 Features 5 Specifications 6 Names of Parts 14 Optional Configuration 20 ...

Page 83: ...Periodical Service 3 Periodic Servicing Tasks 76 ...

Page 87: ...3 Remove the 2 Connectors 1 2x 1 4 Parts Replacement and Cleaning 79 ...

Page 89: ...Main Units Parts 4 5 6 7 8 1 2 3 4 Parts Replacement and Cleaning 81 ...

Page 128: ...4x 1 2 2 3 3 2x 4 Parts Replacement and Cleaning 120 ...

Page 150: ...Adjustment 5 Overview 143 Basic Adjustment 148 Adjustments When Replacing Parts 173 Other 184 ...

Page 193: ...Troubleshooting 6 Making Initial Checks 186 Processing Tray Area 187 Saddle Stitcher Area 188 ...

Page 204: ...4 5 6 7 8 9 7 Installation 196 ...

Page 205: ...10 7 Installation 197 ...

Page 223: ...2 3 2x 7 Installation 215 ...

Page 224: ...APPENDICES Service Tools 217 General Circuit Diagram 218 ...