■ Procedure of Adjustment

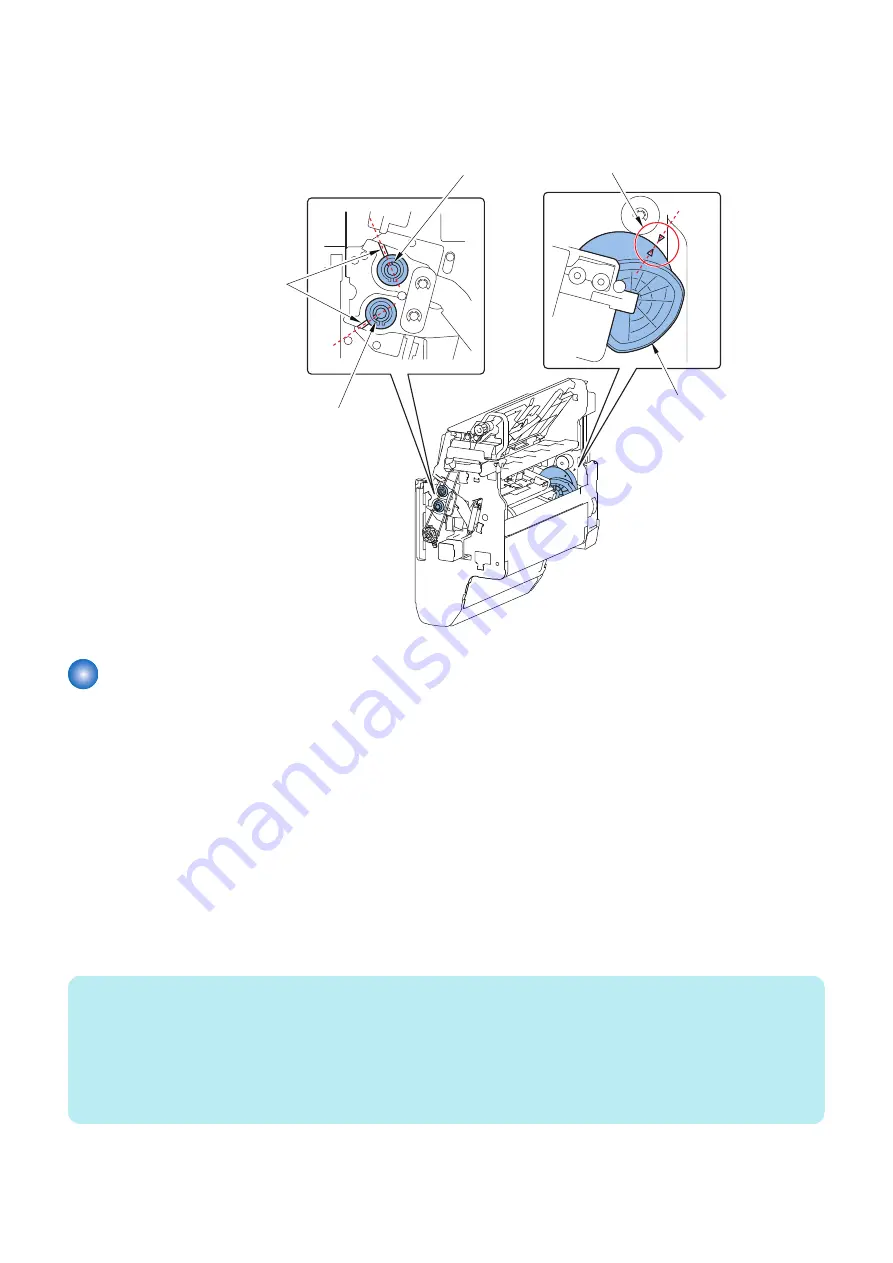

1. With the shaft notches of the paper folding roller (upper and lower) aligned to the support plate grooves, align the

cam mark to the support plate mark, and fix them in place.

Mark

Cam

Cut-out of Lower Paper Folding Roller

Mark

Cut-out of Upper Paper Folding Roller

Handling Finisher Controller PCB Replacements

■ Handling before replacement

• When backup is possible

1. Before replacing the finisher controller PCB, back up the counter values of consumable parts and various adjustment

values to the host machine in the host machine's service mode.

- (Lv.1) SORTER > FUNCTION > FIN-BK-R

2. To execute back up, turn the main power on the host machine off and then on.

3. Turn the main power of the host machine off.

• When backup is not possible

1. Before replacing the finisher controller PCB, output P-PRINT in the host machine's service mode.

- (Lv.1) COPIER > FUNCTION > MISC-P > P-PRINT

2. Turn the main power of the host machine off.

■ Handling after replacement

NOTE:

If the finisher version is old, a message prompting you to update will appear. If this message appears, update it automatically. If

you select to skip the message screen indicating that the combination is not correct, the message will appear every time you start

the host machine unless you disable the message in service mode.

(Lv.2) COPIER > OPTION > FNC-SW > VER-CHNG

Setting of firmware update operation

5. Adjustment

180

Summary of Contents for Staple Finisher-AA1

Page 1: ...Revision 4 0 Staple Finisher AA1 Booklet Finisher AA1 Service Manual ...

Page 12: ...Product Overview 1 Features 5 Specifications 6 Names of Parts 14 Optional Configuration 20 ...

Page 83: ...Periodical Service 3 Periodic Servicing Tasks 76 ...

Page 87: ...3 Remove the 2 Connectors 1 2x 1 4 Parts Replacement and Cleaning 79 ...

Page 89: ...Main Units Parts 4 5 6 7 8 1 2 3 4 Parts Replacement and Cleaning 81 ...

Page 128: ...4x 1 2 2 3 3 2x 4 Parts Replacement and Cleaning 120 ...

Page 150: ...Adjustment 5 Overview 143 Basic Adjustment 148 Adjustments When Replacing Parts 173 Other 184 ...

Page 193: ...Troubleshooting 6 Making Initial Checks 186 Processing Tray Area 187 Saddle Stitcher Area 188 ...

Page 204: ...4 5 6 7 8 9 7 Installation 196 ...

Page 205: ...10 7 Installation 197 ...

Page 223: ...2 3 2x 7 Installation 215 ...

Page 224: ...APPENDICES Service Tools 217 General Circuit Diagram 218 ...