Service Mode

Items

SORTER > ADJUST

CENT-ALG

Adjusting the center standard position of the alignment plates

SDL-STP2

Adjusting the stitching position of the saddle stitcher unit (thin paper)

SDL-FLD2

Adjusting the folding position of the saddle stitcher unit (thin paper)

ESC1-SPD

Adjusting the delivery speed of the escape tray

SFT-SPD

Adjusting the delivery speed at the shift sort mode

STP-SPD

Adjusting the delivery speed at the staple mode

RBLT-PS2

Adjusting the height of the return belt

RBLT-PS3

Adjusting the height of the return belt

SORTER > OPTION

BUFF-SW

Setting ON/OFF of the buffer operation

1SHT-SRT

Setting ON/OFF of the shift sort delivery operation for a sheet of

paper

FIN-SP1

Finisher special settings 1

FIN-SP2

Finisher special settings 2

MSTP-TMG

Setting the staple timing at the manual staple mode

PNCH-SW3*

Setting ON/OFF of the mode to improve the precision of the punch

hole position

SFT-CHNG

Setting the delivery number of the stacking paper at the shift sort

mode

STP-ALG

Setting the operation of the alignment plates at the staple and sta-

plefree binding mode

SDL-ALG

Setting the paddle operation when stacking the paper in the saddle

stitcher unit

TRY-STP

Setting whether to limit the stack capacity of the stapled or folded

sheets

TRY-LMT

Setting whether to limit the stack capacity of the stack tray

*: The adjustment and setting values of this service mode for the puncher unit are stored by the finisher. The adjustment and

setting values of the following service mode are stored by the puncher unit.

• (Lv.1) SORTER > ADJUST > PNCH-Y

• (Lv.1) SORTER > OPTION > PUN-Y-SW

• (Lv.1) SORTER > OPTION > PNCH-SW2

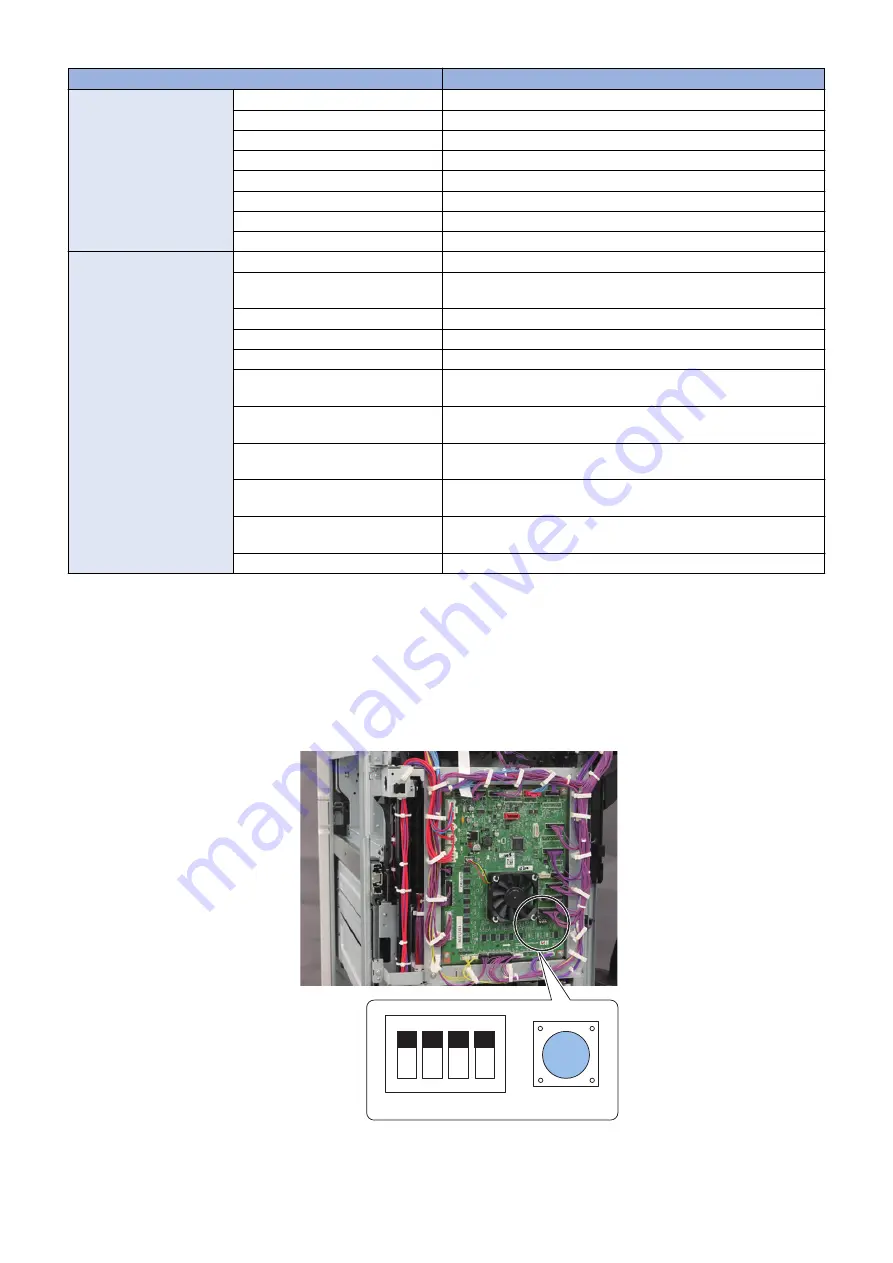

If there is not the output of the "P-PRINT"

1. Set the SW1 keys as shown below and press the SW2.

ON

1

2

3

4

SW1

SW2

5. Adjustment

182

Summary of Contents for Staple Finisher-AA1

Page 1: ...Revision 4 0 Staple Finisher AA1 Booklet Finisher AA1 Service Manual ...

Page 12: ...Product Overview 1 Features 5 Specifications 6 Names of Parts 14 Optional Configuration 20 ...

Page 83: ...Periodical Service 3 Periodic Servicing Tasks 76 ...

Page 87: ...3 Remove the 2 Connectors 1 2x 1 4 Parts Replacement and Cleaning 79 ...

Page 89: ...Main Units Parts 4 5 6 7 8 1 2 3 4 Parts Replacement and Cleaning 81 ...

Page 128: ...4x 1 2 2 3 3 2x 4 Parts Replacement and Cleaning 120 ...

Page 150: ...Adjustment 5 Overview 143 Basic Adjustment 148 Adjustments When Replacing Parts 173 Other 184 ...

Page 193: ...Troubleshooting 6 Making Initial Checks 186 Processing Tray Area 187 Saddle Stitcher Area 188 ...

Page 204: ...4 5 6 7 8 9 7 Installation 196 ...

Page 205: ...10 7 Installation 197 ...

Page 223: ...2 3 2x 7 Installation 215 ...

Page 224: ...APPENDICES Service Tools 217 General Circuit Diagram 218 ...