2. In the case the paper displacement occurs after performing Step 1 adjustment, stop the buffer movement by the

following service mode.

• SORTER > OPTION > BUFF-SW = 1

.

CAUTION:

Productivity is reduced in this mode.

3. In the case paper displacement occurs after performing Step 2, it is not buffer factor. Set 0 for the buffer adjustment

value.

• SORTER > OPTION > BUFF-SW = 0

1. After setting 0 for the buffer adjustment value, adjust height of Swing Unit and Return Roller.

“Adjusting the Return Roller/Swing Unit Height ” on page 155

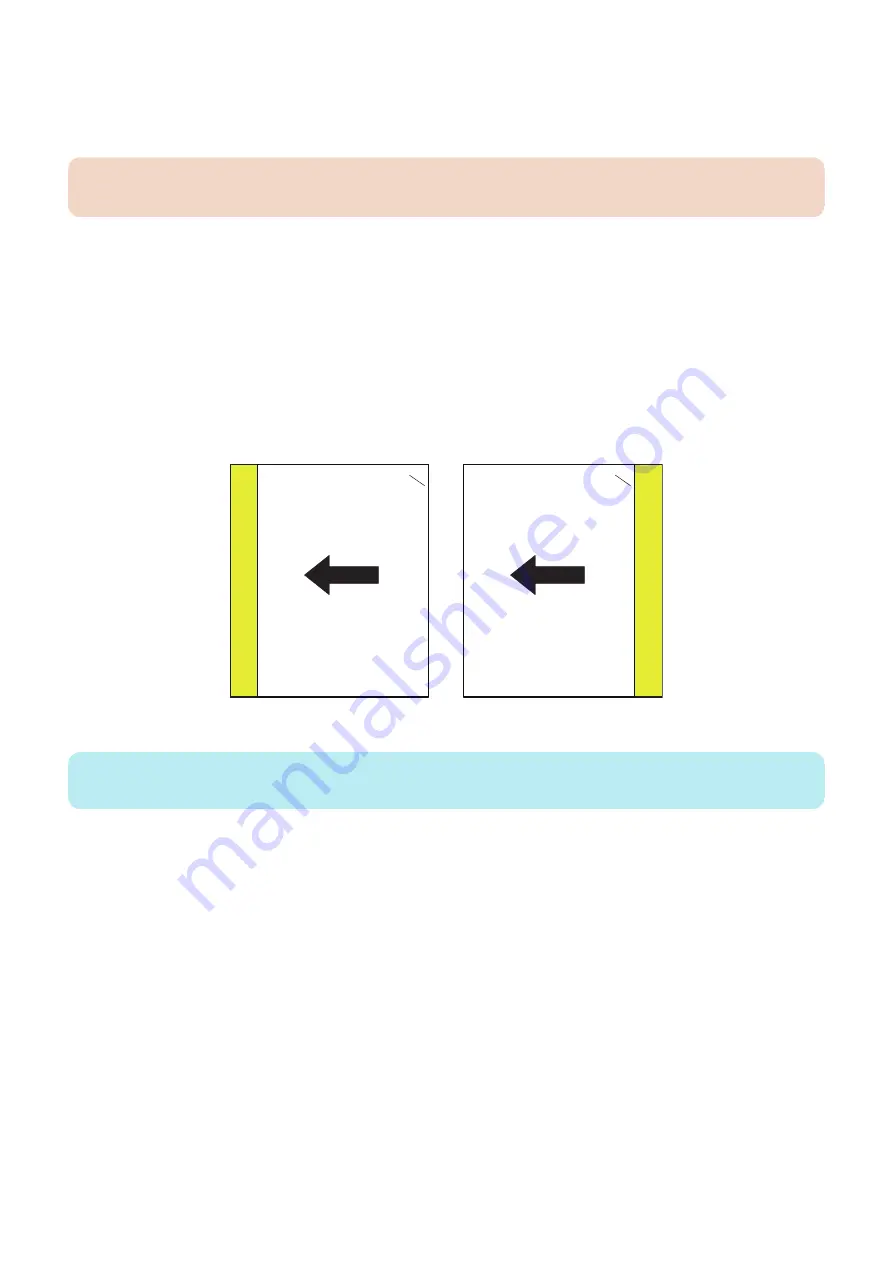

■ Adjusting the Return Roller/Swing Unit Height

<Use case>

• When misalignment occurs in feed direction.

• When misalignment occurs by failure of the paper feeding to processing tray.

Feed Direction

Feed Direction

<Procedure of adjustment>

NOTE:

After the setting value is changed, write the changed value in the service label.

5. Adjustment

155

Summary of Contents for Staple Finisher-AA1

Page 1: ...Revision 4 0 Staple Finisher AA1 Booklet Finisher AA1 Service Manual ...

Page 12: ...Product Overview 1 Features 5 Specifications 6 Names of Parts 14 Optional Configuration 20 ...

Page 83: ...Periodical Service 3 Periodic Servicing Tasks 76 ...

Page 87: ...3 Remove the 2 Connectors 1 2x 1 4 Parts Replacement and Cleaning 79 ...

Page 89: ...Main Units Parts 4 5 6 7 8 1 2 3 4 Parts Replacement and Cleaning 81 ...

Page 128: ...4x 1 2 2 3 3 2x 4 Parts Replacement and Cleaning 120 ...

Page 150: ...Adjustment 5 Overview 143 Basic Adjustment 148 Adjustments When Replacing Parts 173 Other 184 ...

Page 193: ...Troubleshooting 6 Making Initial Checks 186 Processing Tray Area 187 Saddle Stitcher Area 188 ...

Page 204: ...4 5 6 7 8 9 7 Installation 196 ...

Page 205: ...10 7 Installation 197 ...

Page 223: ...2 3 2x 7 Installation 215 ...

Page 224: ...APPENDICES Service Tools 217 General Circuit Diagram 218 ...