COPYRIGHT© 2002 CANON INC.

2000

CANON BOOKLET TRIMMER-A1 REV.0 FEB. 2002

USER MODE

U-7

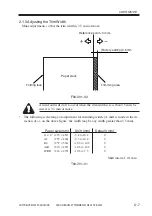

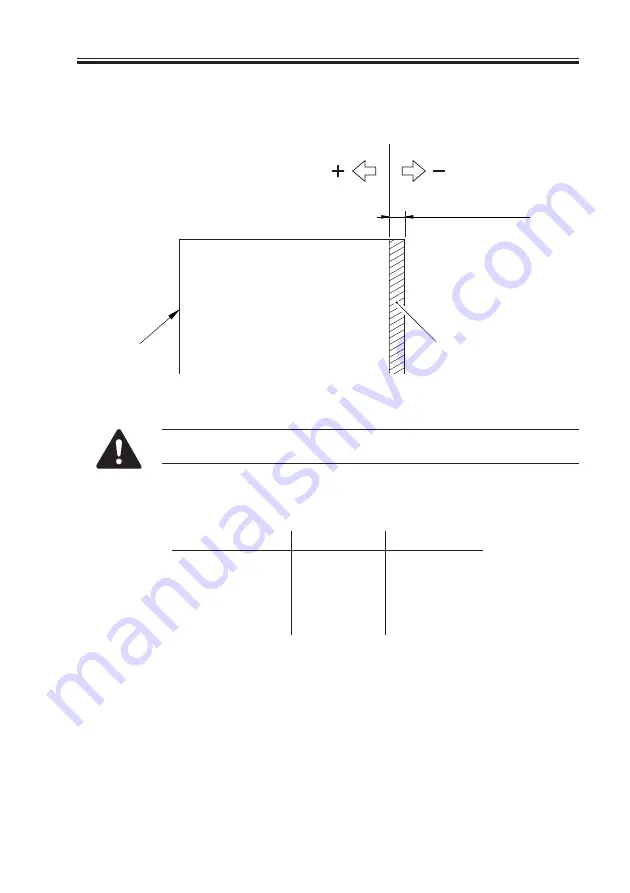

2.1.3 Adjusting the Trim Width

Make adjustments so that the trim width is 3.5 mm or more.

F00-201-02

A trim fault will start to occur when the trim width is less than 3.5 mm; be

sure it is 3.5 mm or more.

•

The following is the range of adjustment for trimming width. (A shift is made in the di-

rection of +/- on the above figure; the width may be any width greater than 3.5 mm).

T00-201-01

[Factory setting] 3.5 mm

Reference point <0 mm>

Paper stack

Trimming area

Folding face

Paper size (mm)

11 × 17 (279 × 432)

A3

(297 × 420)

B4

(257 × 354)

A4R

(210 × 297)

LTRR

(216 × 279)

Shift (mm)

-3.4 to 10.2

-9.5 to 10.2

-10.3 to 10.2

-10.3 to 10.2

-10.3 to 7.3

Default (mm)

0

0

0

0

0

Shift interval: 0.1 mm

Summary of Contents for Two-Knife Booklet Trimmer-A1

Page 129: ...COPYRIGHT 2002 CANON INC 2000 CANON BOOKLET TRIMMER A1 REV 0 FEB 2002 CHAPTER 6 APPENDIX ...

Page 132: ...User Mode COPYRIGHT 2002 CANON INC 2000 CANON BOOKLET TRIMMER A1 REV 0 FEB 2002 ...

Page 141: ...Service Mode COPYRIGHT 2002 CANON INC 2000 CANON BOOKLET TRIMMER A1 REV 0 FEB 2002 ...