varioPRINT 135 Customer Expectations Document

Version 13

varioPRINT 135 Customer Expectations Document

Page 59

11. Consumables

Consumables are all products and materials that are consumed with regular use

and cannot be reused. Such consumables include, but are not limited to, paper,

chemicals, and toner. A number of factors go into the approximate life expectancy

of a consumable item, including paper size and the amount of coverage per page.

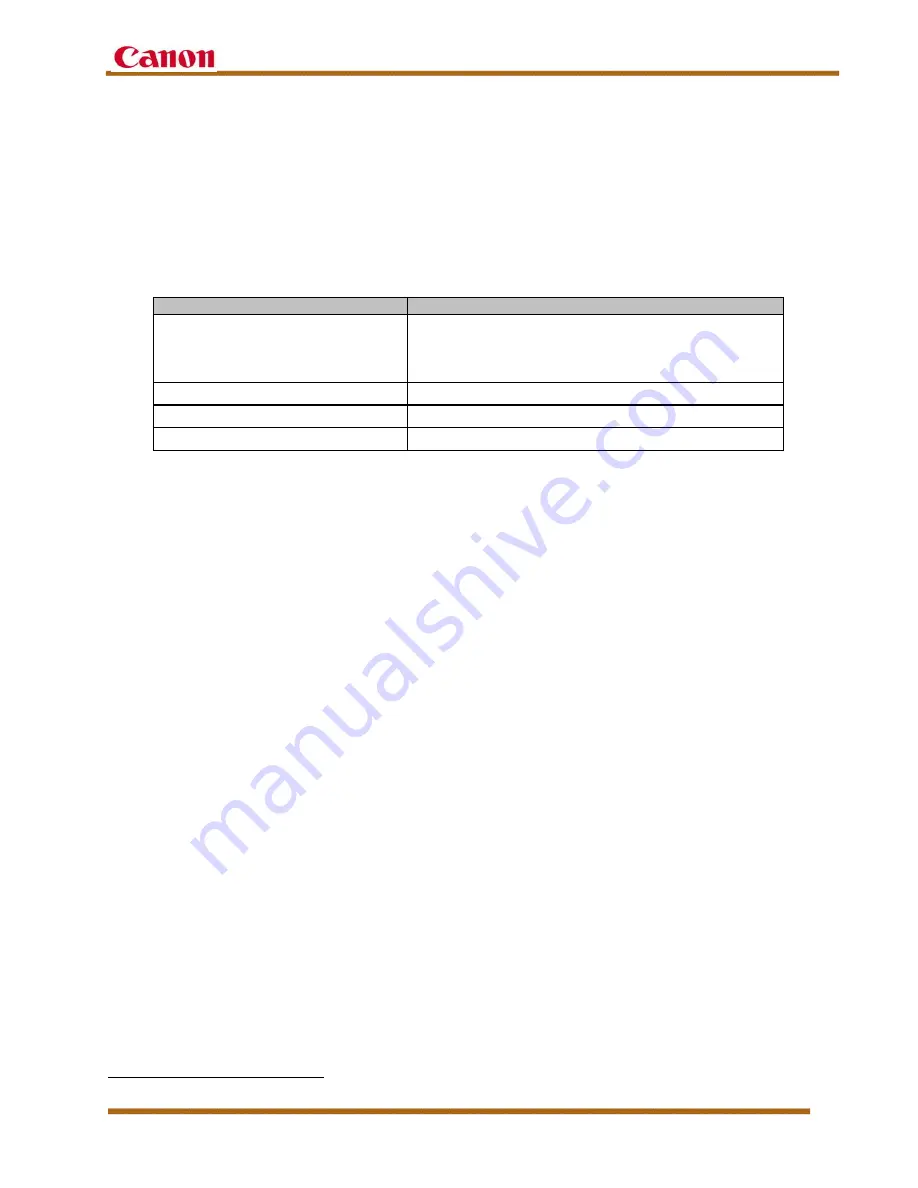

Operate the machine within the following usage conditions to achieve optimal

machine performance.

Item

Condition

Operating Temperature

•

62.6°F to 78.8°F (17°C to 26°C) for print speeds greater

than 120 ipm.

•

62.6°F to 82.4°F (17°C to 28°C) for print speeds up to

120 ipm.

Operating Humidity

20% to 80%

Optimal Performance Range Per Month

80,000 to 800,000

Image Ratio

6%

11.1 Consumable Parts

Consumable parts are defined as those parts having a limited life that will be

reached during a customer’s specific machine operation, and then should be

replaced as needed. Examples of consumable parts include, but are not limited to

feed rollers, cleaning blades, and fixing assembly components.

An estimated consumable parts life can be provided by a service technician to

assist in the initial parts/supplies planning. A consumable part’s life expectancy is

directly related to usage factors, such as paper size, paper quality, environment,

usage application, and machine maintenance. Therefore, consumable parts do not

have a warranty, and Canon U.S.A., Inc. cannot guarantee a minimum life.

48 Based on 20 lb LTR-size paper, and under the above optimal environmental conditions.