varioPRINT 135 Customer Expectations Document

Version 13

varioPRINT 135 Customer Expectations Document

Page 68

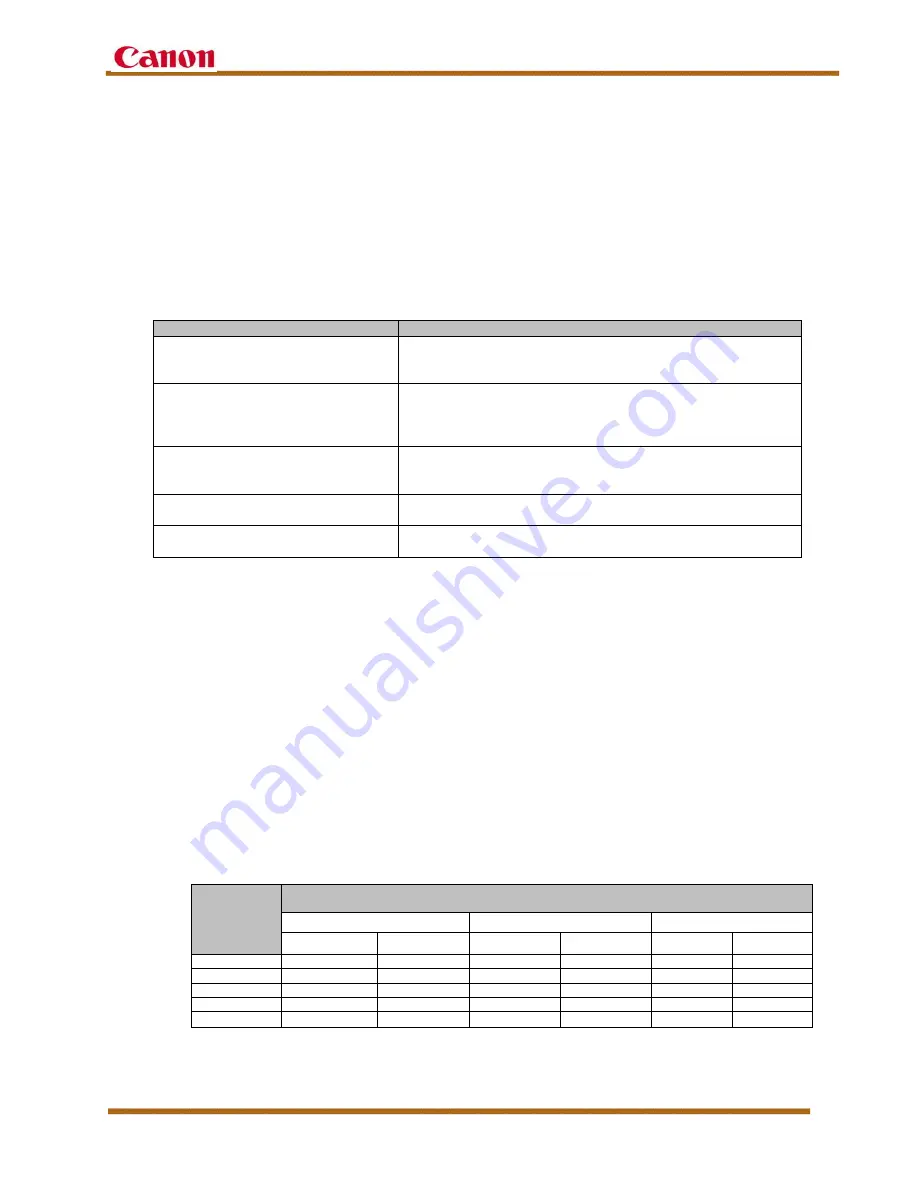

16.3 Advanced Media Settings

The Advanced media settings are for customers who want to use advanced print

settings to avoid certain print quality issues.

The following settings can be adjusted from the operator panel through System >

Setup > Advanced media settings.

The table below describes the Advanced media settings and each setting’s

description.

Setting

Description

Pre-printed mode

Select if preprinted media is being used without following the

recommended guidelines for preprinted media. This mode

reduces the print speed to 60 ipm.

Wax mode

*2

Select if wax paper

*1

is being used, or if there are print quality

issues, such as spotting, lines, or smearing on any paper type.

After printing in the Wax mode is complete, select the Wax mode

to disable it.

*3

Paper quality

Specify the Paper quality mode to improve the print quality if

low-quality paper is being used to avoid leaving uneven, dark

areas on the prints.

Automatic Drum Cleaning

Select if random spotting appears repetitively on the output. This

may be due to glue particles adhering to the drum unit.

*4

Decurl Adjustment

Select to adjust the paper curl amount per media type, and

whether the output is face-up or face-down.

*1 Wax paper is a type of paper that is made moisture-proof through the application of wax.

*2 The machine has two Wax modes (‘1’ and ‘2’). Each Wax mode safely preheats the system to prevent

the deposition of wax. Select Wax mode ‘1’ when there are print quality issues with wax paper or any

paper type. Select Wax mode ‘2’ if Wax mode ‘1’ does not resolve the print quality issues. Wax mode ‘2’

requires a higher start-up temperature, which increases the start-up time of the machine, and requires

more time for the decomposition of the wax. After printing in the Wax mode is complete, the system is

cleaned automatically, and the machine remains in the Standby mode so that the remaining wax can be

decomposed.

*3 The more the Wax mode is used, the longer the machine needs to decompose the wax. To get optimal

performance results using the Wax mode, do not print more than 50,000 sheets of wax paper. However,

if more printing is needed, let the machine remain in the Standby mode to decompose the wax, or

perform print jobs that do not require wax paper. After using wax paper, do not power OFF the machine

or put the machine into the Sleep mode. Leave the machine in the Standby mode to allow it to clean the

wax components. After a maximum of 2 hours in the Standby mode, the machine switches to the Sleep

mode automatically. If 2 hours is not enough time to decompose all of the wax, the machine remains in

the Standby mode after the next job, until all of the wax is cleaned.

*4 During the printing process, glue particles, which are an inherent part of recycled paper or glue that

transfers from the paper package, can be transferred to the drum unit and cause spotting. The

Automatic Drum Cleaning procedure can clean the glue from the drum. However, when the Automatic

Drum Cleaning setting is used, print productivity is affected, as seen in the chart below. Note that not all

kinds of glue are removable by the Automatic Drum Cleaning procedure.

Detection

Interval

(After Every

“x” Number

of Sheets)

Productivity (ipm)

100/110

110/120

120/135

Simplex

Duplex

Simplex

Duplex

Simplex

Duplex

350

100

110

110

120

120

135

200

101

109

111

118

121

133

100

99

105

109

114

118

128

50

96

98

105

106

114

119

20

88

82

96

89

104

99