38

l

Can

BREEZE

Operating and Maintenance Cooling Unit Instructions 8-14 kW

www.canovate.com

l

info@canovate.com

l

P. +90 216 484 2222

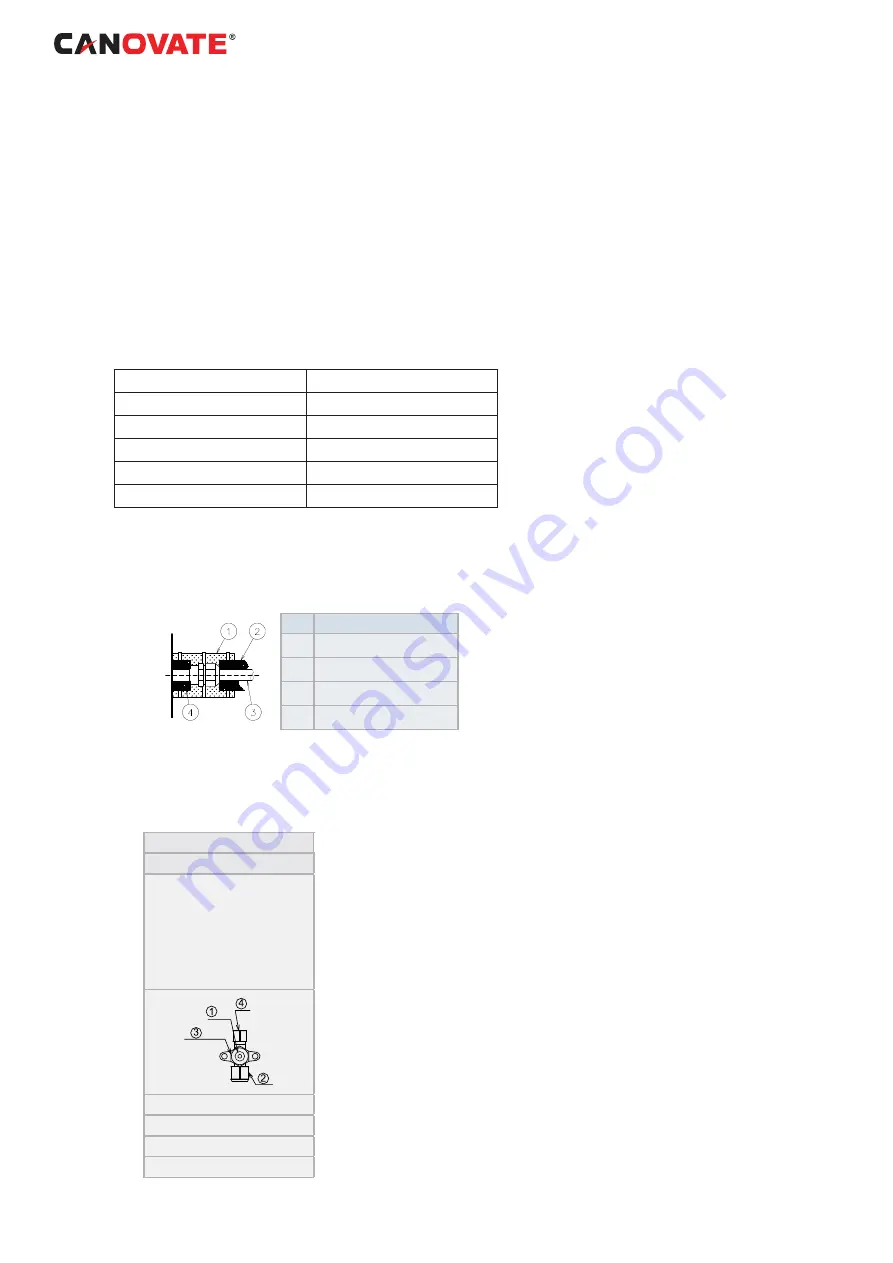

entering into the unit. Seal the holes where pipes

and wires are inserted, by using a insulation (

fi

eld-

supplied).

3

If the

fi

eld-supplied piping is connected with

stop valves di- rectly, it is recommended use a tube

bender.

4

Check to ensure that the stop valves are closed

completely before connecting pipes.

5

Connect the

fi

eld supplied refrigerant pipes to

the indoor unit and outdoor unit. Apply the oil thinly at

the seat

fl

are nut and pipe before tightening.

The required tightening torque is as follows:

Pipe Size

Tightening Torque (Nm)

Ø 6.35 mm (1/4)

20

Ø 9.53 mm (3/8)

40

Ø 12.70 mm (1/2)

60

Ø 15.88 mm (5/8)

80

Ø 19.05 mm (3/4)

100

6

After connecting the refrigerant piping, seal the

open space between knockout hole and refrigerant

pipes by using insula- tion material

Unit

Side

Nº

Description

1

Insulation Material

2

Insulation Material

3

Field Supplied

4

Insulation Material

7

Operation of stop valve should be performed

according to the

fi

gure below.

Close before shipment

Outdoor unit stop valve

Spindle Type

8-14 kW

1

2

3

4