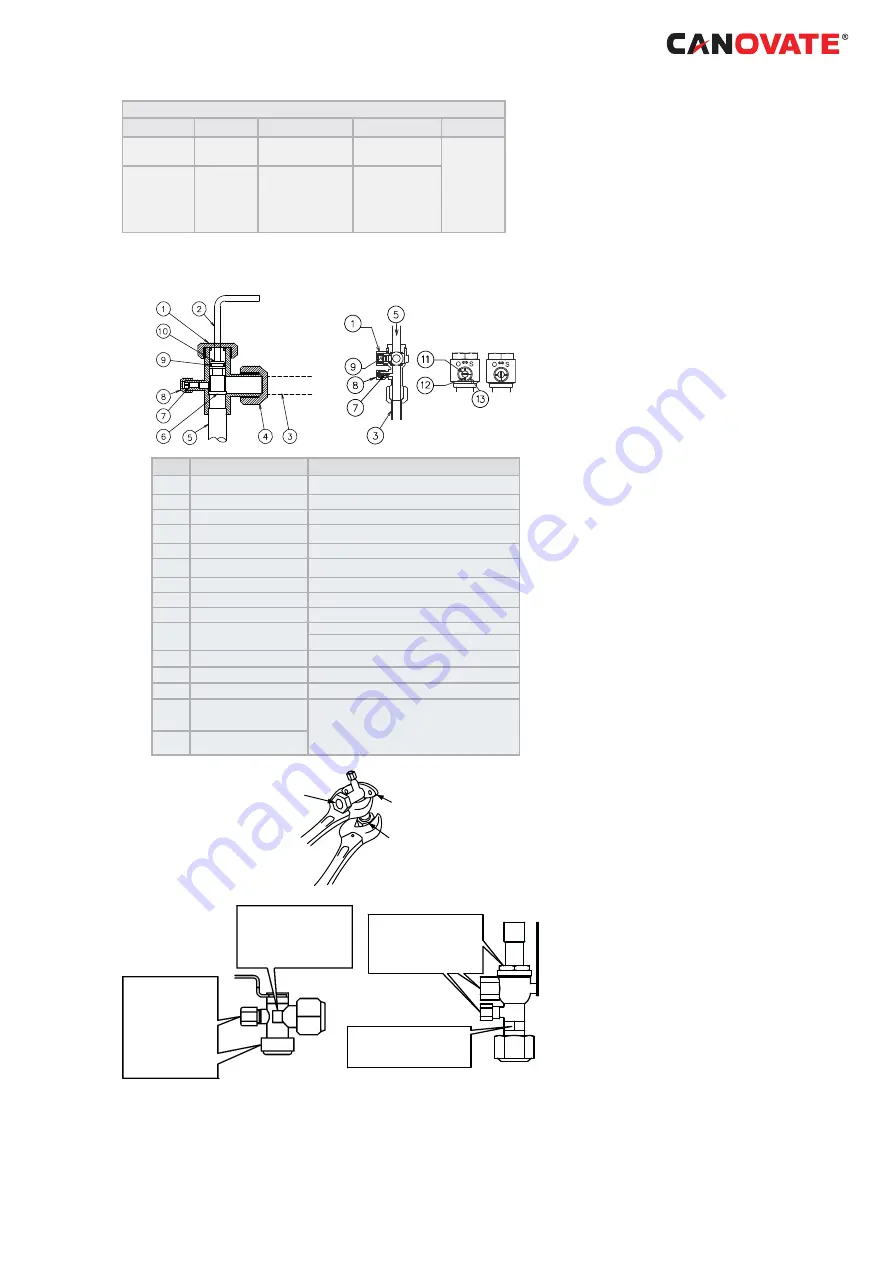

Tightening Torque (Nm)

1

2

3

4

Liquid valve

7-9

40

10HP: 60

33-42

14-18

Gas valve

9-11

80

8/10HP: 100

3HP: 33-42

4/5/6HP:

P=20-25

S/C=33-42

8/10HP:20-25

Spindle Type

Ball Type

(a)

(b)

Nº

Description

Remarks

1

Cap

2

Allen wrench

Hex 4 mm

3

Refrigerant Piping

Field Supplied

4

Flare nut

5

Refrigerant Pressure

To Outdoor Unit

6

Seat Surface

Fully closed position

7

Check Joint

Only the charging those can be connected

8

Charge port cap

9

O-Ring

Rubber

10

Spindle valve

Open – Counterclockwise

Close – Clockwise

11

Shaft

12

Pin

13

Stopper

(a)

Closed

This valve is opened or closed with rotating 90

degrees at the ball valve part. Rotate the shaft

until the pin touches the stopper. Do not apply the

extra force. Use a slotted screwdriver to control

the shaft. Do not leave the ball valve partly ope

n

(b)

Opened

Do not apply two spanners

at this position. If applied,

leakage will occur.

Stop valve

(Spindle type)

Flare nut

Use two spanners

here for pipe con-

nection

Do not work with

two spanners

here.

Refrigerant

leakage shall

occur

Position to apply

spanners

Don not apply

two spanners

work here

Spindle type

Ball type

C A U T I O N

At

the

test

run,

fully

open

the

spindle

and

ball

stop

valve. If not fully opened, the devices will be damaged.

www.canovate.com

l

info@canovate.com

l

P. +90 216 484 2222

Can BREE

ZE

Operating and Maintenance Cooling Unit Instructions 8-14 kW

l

39