- 11 -

There are a total of four fences on the 40-050

Dovetailer - two vertical and two horizontal. These

allow two sets of workpieces to be cut at the same

time. If this is desired, position the other two fences in

the same manner as the first two fences, remembering

again to offset the vertical fence by half the pitch.

Buffer Pads

The polyethylene buffer pads, shown in Figure 18,

have slots through which they are secured to the

fences by screws. These buffer pads can be

re-positioned if needed.

To adjust a buffer pad, loosen the two hex cap screws

(shown in Figure 18) with a 13mm wrench. Slide the

buffer pad as necessary. Retighten both hex cap

screws when finished.

Cutter Height

This adjustment will change the height of the tail on the

tenon (male) cut, and how deep the mortise (female)

cut goes into the thickness of the workpiece.

1. Disconnect machine from power source.

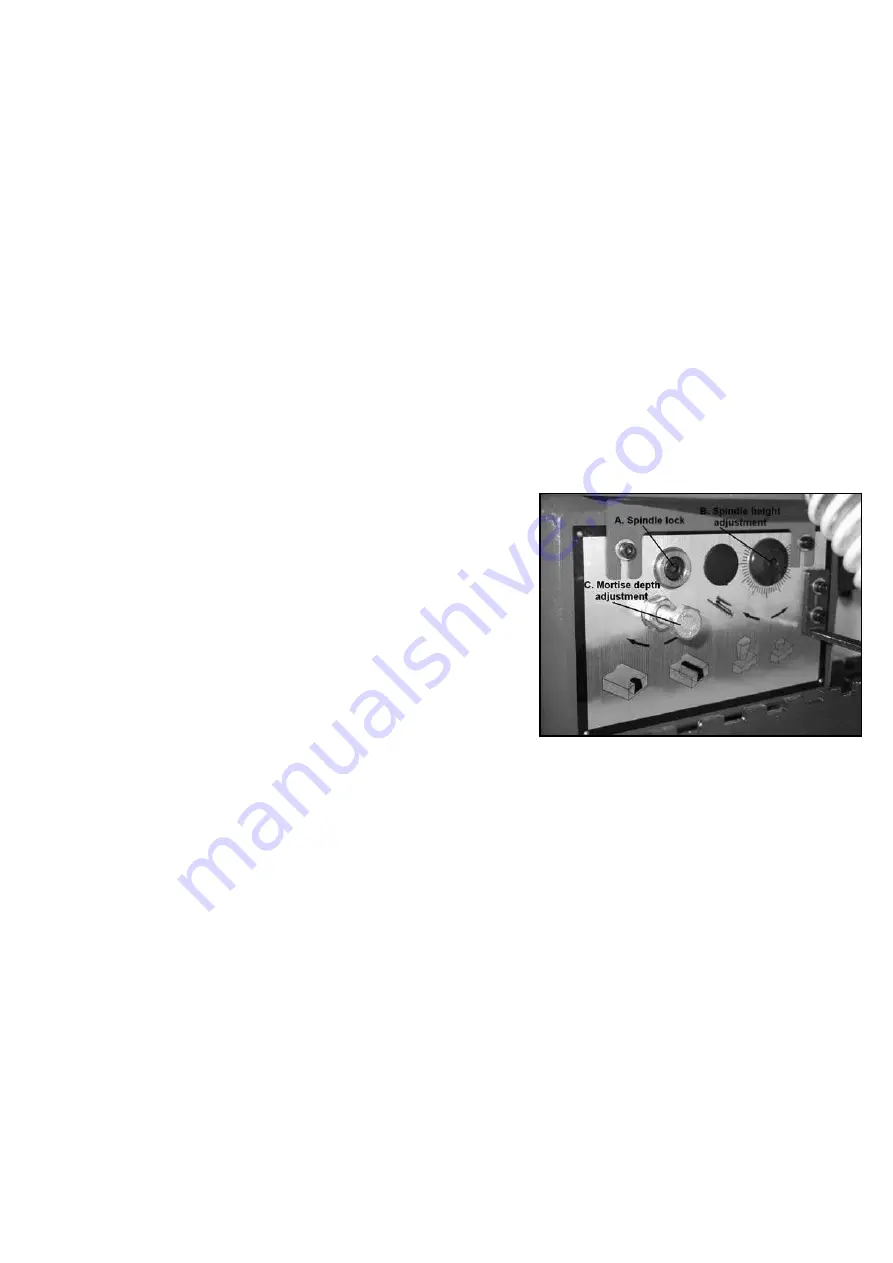

2. Loosen the spindle lock screw (Figure 19) by turning

it counterclockwise with a 6mm hex wrench.

3. Turn the spindle height adjustment screw (Figure 19)

with a 5.5mm hex wrench, either clockwise to raise

the cutter (increase the cutter depth), or

counterclockwise to lower the cutter (decrease the

cutter depth).

4. Tighten spindle lock screw by turning it clockwise.

Mortise Depth

This adjustment ensures that the side pieces of your

drawer will remain flush with the front and back pieces

of the drawer. The correct fit will have the sides flush

with the front and back of the drawer, without showing

any of the mortise cut on the inside of the drawer.

The mortise depth adjustment bolt, shown in Figure 19,

limits how far forward the headstock will go, and thus

limits the length of your mortise cut.

1. Disconnect machine from power source.

2. Loosen the hex nut on the mortise depth adjustment

bolt (Figure 19) by turning the hex nut

counterclockwise with a 17mm wrench.

Figure 19