8

5-5 Pressure Bar:

Most planing problems can be related to improper setting of the

pressure bar. Its functions are to hold the material down after it

passes under the cutterhead and throughout the remainder of the the

cut. Its basic setting is to be in line with the arc of cutterhead knives.

If it is too high, a shallow clip will occur in each end of the board.

If it is too low, stock will not feed through. (Fig. 10) With a bed and

feed roll gage or a gage block and a 1/32" (0.81mm) thick 6"

(152mm) scale as a feeler placed under the cutterhead, raise the

table with its elevating handwheel to determine the low point of the

arc of a cutterhead knife. Move the gage or gage block and scale

under the low point of the extreme right hand side of the table and

adjust that end of the pressure bar to be in line with the low point of

the knife arc. Move the gage of gage block and scale to the extreme

left hand side and adjust that side to be in line with the low point of

the knife arc. Using the bed and feed roll gage set the full length of

the pressure bar to be. 000-0.001(0.02mm) above the arc of the

cutterhead. This initial setup is a staring point and final adjustment

may have to be made during a test cut.

Fig. 10

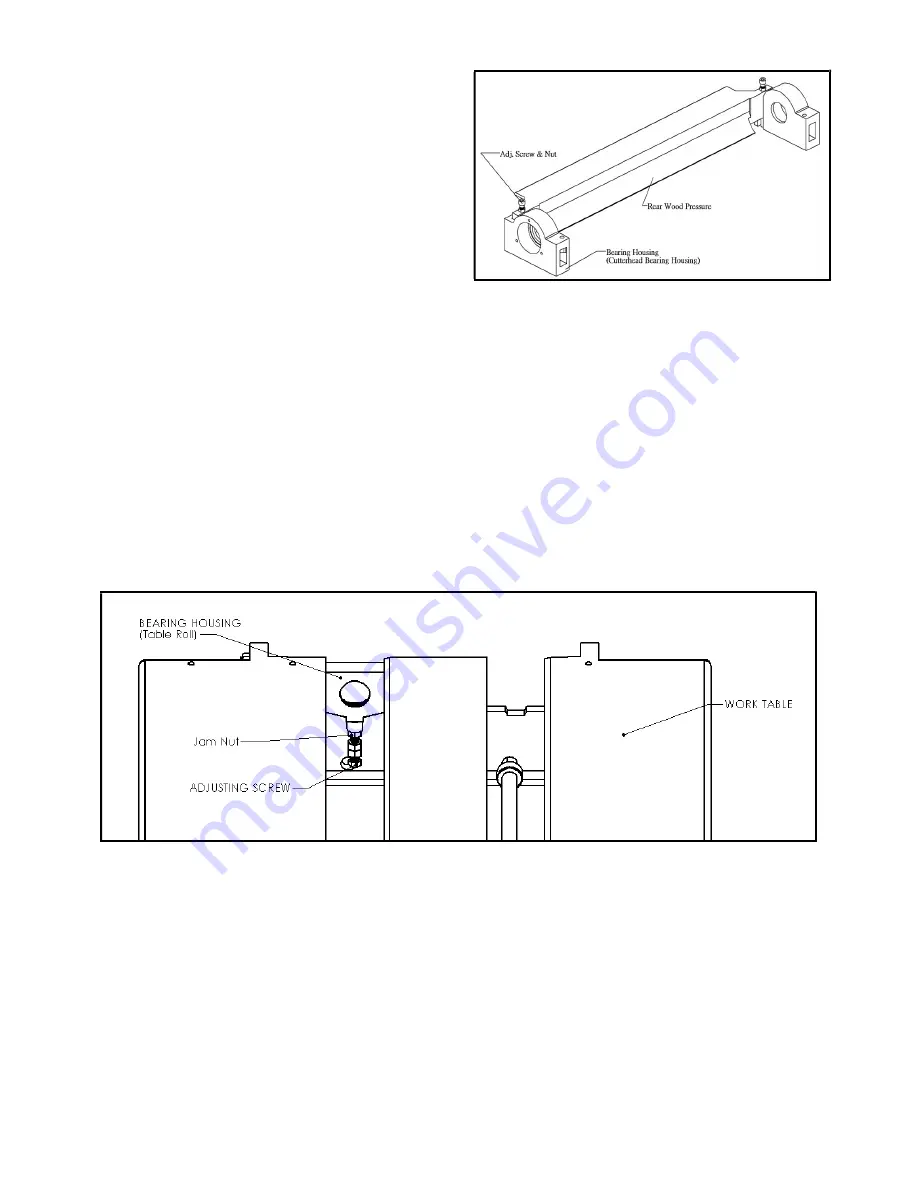

5-6 Table rolls

Two table rolls are provided on the planer to help reduce the friction of the stock on the table as it feeds through the machine.

The required height of table rolls are according to that whether the bottom face of stock is flat or rough. The standard setting is 0.007" above

the table, if the gage shows the position is too height or too low. Lossen the jam nut just beneath the bearing hou.sing, and turn the adjusting

screw until the proper position then lock the jam nut (Fig. 7)

Fig. 7

5-7 Test cutting

Using a piece of semi-finished stock, set up for a 1/16" (1.58mm) deep cut with the quick-set adjustment at zero. Start the machine, and

standing to the left-hand side begin feeding the stock into the machine.

CAUTION: Never stand dircctly behind stock or allow anyone else to do so and do not bend down to see how the stock is feeding. Should a

kickback occur, a serious or fatal injury could result.

The infeed roll should take the material and force it under the chip breaker and cutterhead. If the material feeds through effortlessly, examine

the finished cut carefully for imperfections. Learning to read a board for imperfections will save hours in adjusting a planer to operate

properly. If "chip" marks occur in each end of the board, the pressure bar is too high. Turn both right and left hand adjusting screws the same

amount, and take another 1/16" (1.58mm) deep cut.