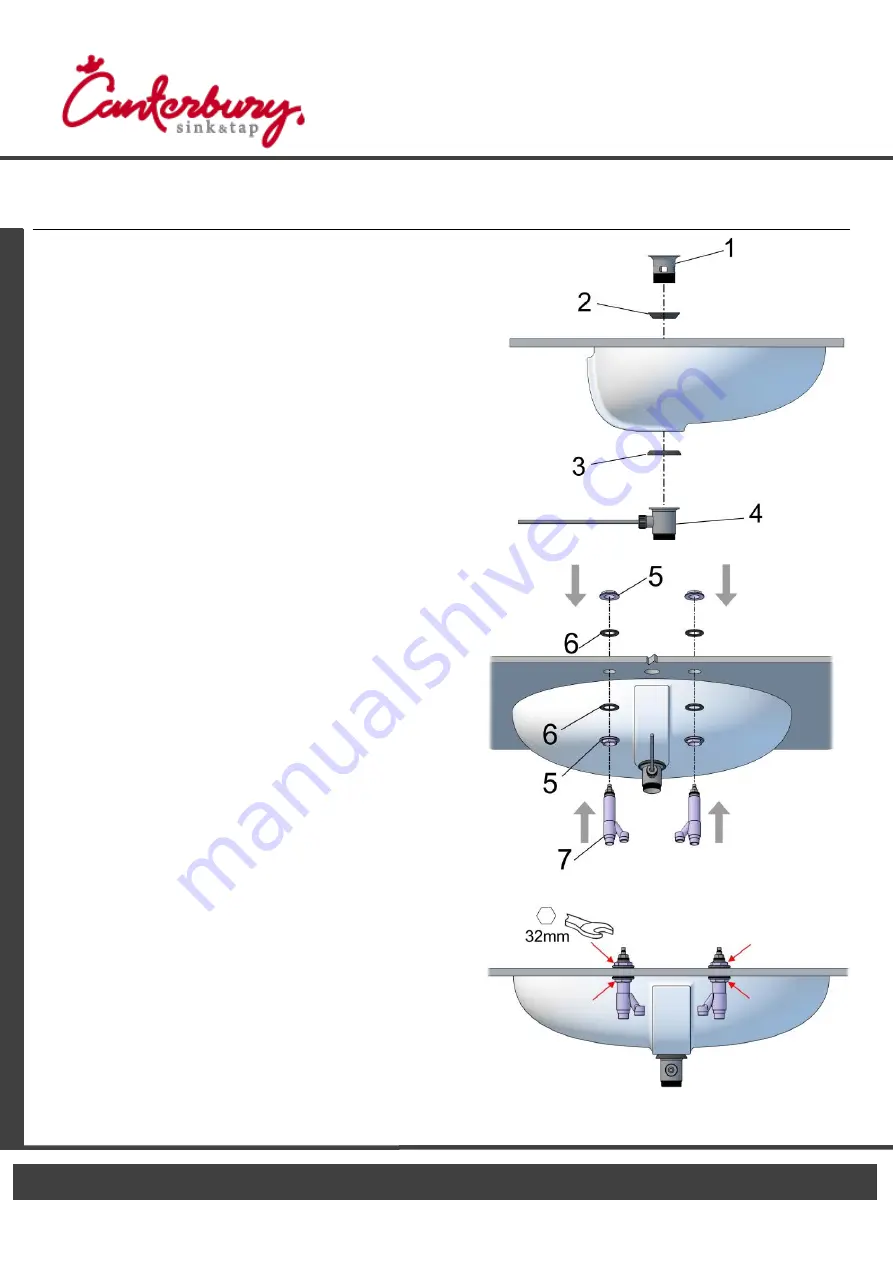

Installation Instructions Model : Z1408

Further information Phone (03) 9761 4603 sales@sinkandtap.com.au

❷

❸

Thread the bottom brass lock nut

5

, followed by

the bottom rubber washer

6

, onto the Side

body

7

, thread section.

Repeat for the opposite side.

Insert the Side body

7

, through the tap hole cut

outs in the counter top.

Feed the top rubber washer

6

, over the thread

section followed by the top brass lock nut

5

.

Note: Make sure that the locking nuts are

fully tightened, otherwise the side body may

turn while turning the On Off lever.

4

❶

Install the pop-up waste body top section

1

, and waste

body bottom section

4

, to the basin as shown.

Ensure that the top seal

2,

and bottom seal

3

, are

installed correctly, to ensure proper functioning of the

pop-up waste system and prevent any water leakage.

Continue…….