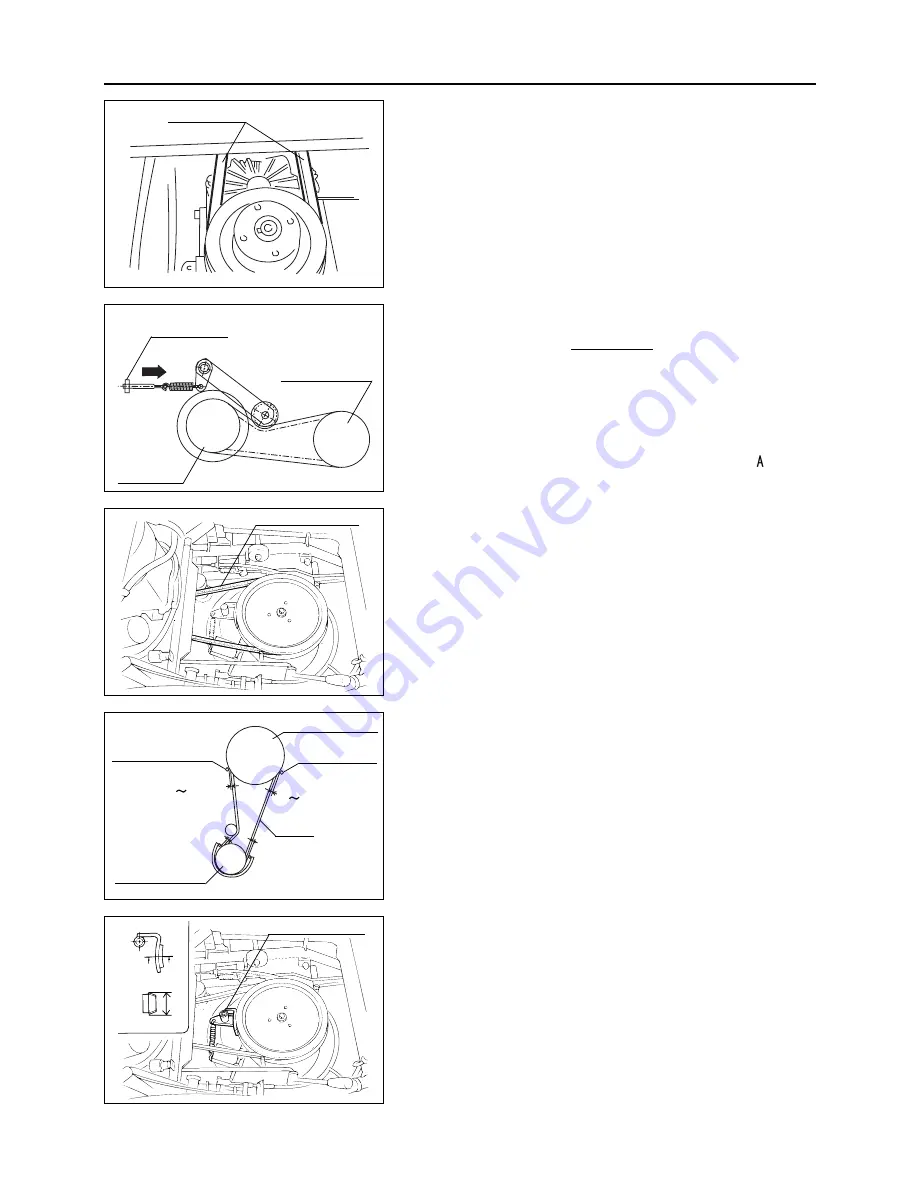

Adjustment

Adjust V belt only when V belt slips during driv-

ing. V belt should be always in tension during

operation.

1. To adjust V belt, turn adjusting nut in direction

.

N O T E

7.8.2

Blade Rotary V Belt

Inspection

1. Visually check for damage on V belt. If any damage is

found, replace the V belt.

Adjustment

After replacing V belt, make adjustment as follows :

1. Set the engine side clearance at belt stopper A 2 to 4 mm

and B 10 mm.

2. Set the clearance between rotary belt holder and V belt

with 3 to 5 mm (when belt slips out of rotary, check the

clearance on belt holder at rotary side).

– 41 –

7

MAINTENANCE

7.8

ADJUSTMENT

7.8.1

V Belt for Driving

Inspection

1. Visually check for damage on V belt. If any damage is

found, replace the V belt.

7.8.3

Rotary Stopper

Inspection

1. Inspect and check whether blade stops within 4 seconds

after putting blade clutch lever to OFF. If cutter does not

stop within 4 seconds, check wearing of lining. If lining

is 20 mm or less, ask the dealer to replace it.

Driving V belt

A

Engine pulley

Adjusting nut

HST pulley

Rotary V belt

Rotary belt holder

Engine pulley

V belt

3

5mm

A

B

3

5mm

20

Rotary belt holder

Cutting blade pulley

Rotary stopper