7.4.3

HST Oil

Inspection/Refilling

1. Park the machine in a horizontal place.

2. Check the amount of oil. When it is insufficient, supply oil (Page 14)

Oil to be used :

page 28

Amount of HST oil: 4.1 lit.

Replacement

1. Prepare a suitable container to collect drained oil.

2. Remove the drain plug and drain oil.

Properly dispose of drained oil.

3. Replace the drain plug.

4. Open the refueling cap and put in a proper amount

of designated oil.

N O T E

– 32 –

MAINTENANCE

Replacement

1. Prepare an appropriate container to collect oil.

2. Remove drain plug and drain oil into container.

Hot oil can cause burns.

CAUTION

Properly dispose of drained oil.

3. Replace drain plug.

4. Open the oil plug and pour the designated oil.

N O T E

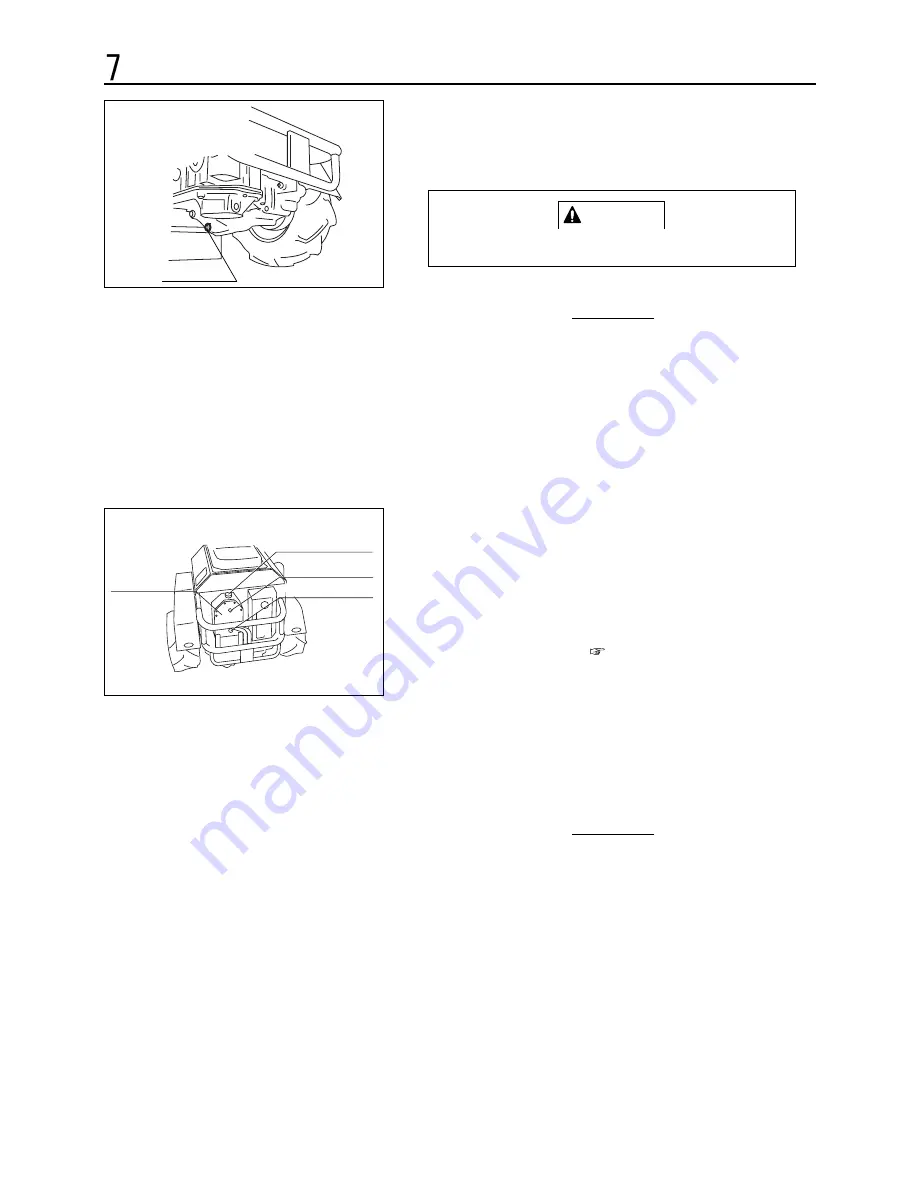

Drain plug

Refueling cap

HST oil tank

Oil checking port

Drain plug