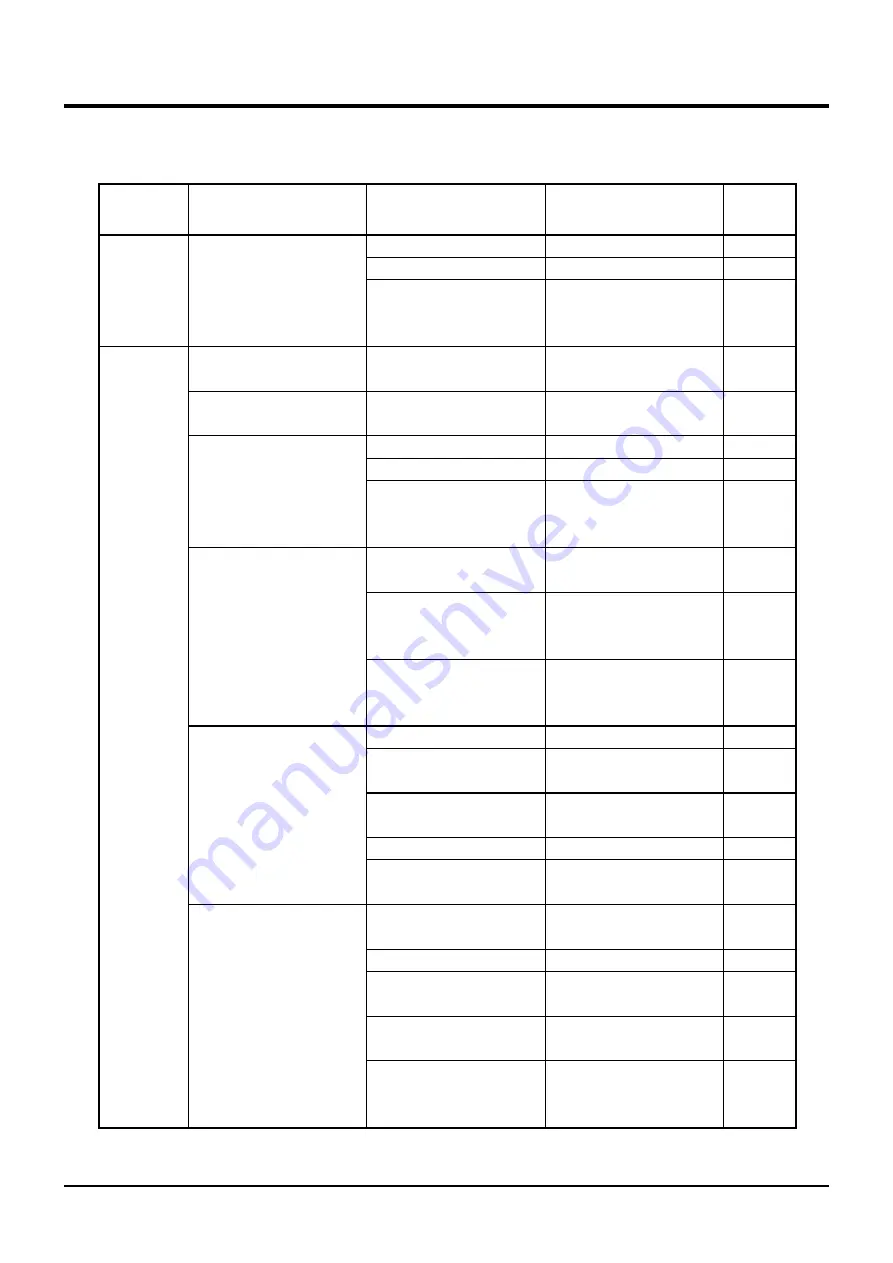

Troubleshooting

-82-

6

Area

Malfunction

Possible Cause

Corrective Measure

Ref.

Electrical

System

Head lamp does not

illuminate properly.

Blown bulb.

→Replace bulb.

Page 74

Blown fuse.

→Replace fuse.

Page 74

Other (other than the

above).

→Please contact

your CANYCOM

representative.

Cutting

System

Cutting blade does not

rotate

Cutting rotary drive

belt is severed.

→Replace.

Cutting blade does not

stop

Brake lining is worn.

→Replace.

Cutting rotary drive

belt slips.

Belt is loose.

→Adjust belt tension.

Page 68

Belt is worn.

→Replace.

Page 68

Cut grass or vines

accumulate in the

cutting blade shield.

→Clean.

Page 75

Abnormal vibration

occurs when cutting

blade is rotated..

Cutting blade is

damaged or lost.

→Replace cutting

blades.

Page 66

Foreign object is

caught by cutting

blade.

→Remove or clean

foreign object.

Other (other than the

above).

→Please contact

your CANYCOM

representative.

Cut grass is not

discharged properly.

Grass is wet.

→

Cut when grass is dry.

Grass is too long.

→Cut in several steps

at different heights.

Cutting height is too

low.

→Raise cutting height.

Engine speed is too low.

→Raise engine speed.

Driving speed is too

high.

→Drive slow.

Some grass is left

uncut.

Grass is too long.

→Cut in several steps

at different heights.

Engine speed is too low.

→Raise engine speed.

Driving speed is too

high.

→Drive slow.

Cutting blade is

damaged or worn.

→Replace.

Cut grass or vines

accumulate in the

cutting blade shield.

→Clean.

Page 75