8

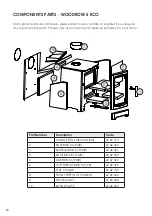

SPECIFIC INSTALLATION INFORMATION

Clearances

If the stoves are to be installed adjacent to materials that can catch fire like wood then

the following clearances must be adhered to:

Clearance to rear = min 400mm (Woodrow 4 Eco), min 200mm (Woodrow 5 Eco)

Clearance to sides = min 400mm (Woodrow 4 Eco, Woodrow 5 Eco)

The stove can be recessed into a suitably sized fireplace built from non-combustible

materials, but a permanent free air gap of at least 100mm should be left around the sides

and top to obtain maximum heat output and for access to the rear of the stove.

It is possible to fit the stove with less clearance around it – down to 50mm, but the non-

combustible material around it must be at least 150mm thick. This is normally achieved

when installing into a standard brick-built chimney breast with double thickness walls to

the rear and sides of the builder’s opening. Take care that the wall finish is suitable to

withstand temperatures of up to 200ºC.

Typical Installation

into In-filled Masonry

Fireplaces

Typical Installation

for Large Chamber

Fireplaces - Rear Flue -

Side View

Summary of Contents for WOODROW 4 ECO

Page 11: ...11 OPERATION AIR CONTROLS TERTIARY PRIMARY ...

Page 22: ...22 NOTES ...

Page 23: ...23 NOTES ...