10

1>. De-solder the capillary and re-solder in the correct position avoiding contact with the inside of the

evaporator, (The depth should be within 15mm), then recharge the unit with refrigerant see

(

→

7)

2>. If the capillary touches the inside of the cabinet or air duct board, you should adjust position of

capillary and pack it with anti-vibration compound.

(Fig.8 & Fig.9

、

Fig.9.1)

Oil jammed noise

Fault: intermittent and deep jet noise coming from inside of the capillary.

Caused by: Compressor oil flowing into the cooling system pipe work because of wine cooler lean during

transportation, and the jetting oil in the capillary cause noise.

Solutions:

Clean the cooling system pipe, and recharge with refrigerant see

(page 7)

▲

Evaporator freezing

○

This is normally due to

A/ Poor seal between door and door frame

B/ The door not closed correctly for a long period of time

This allows moist air into the cabinet, which freezes in the evaporator, if the ice is allowed to get too thick, it

may damage the fan.

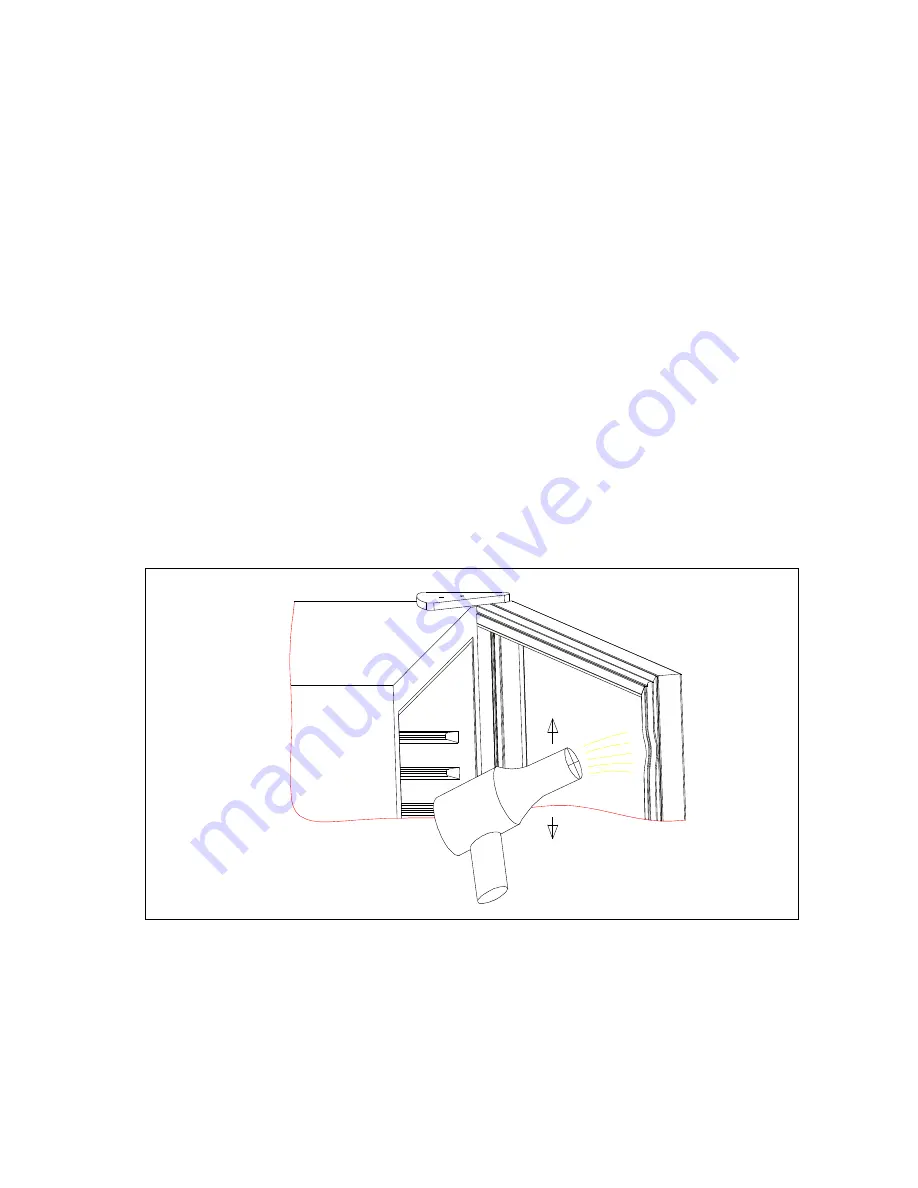

1>. Ensure door is sealed against the frame, if there is slight distortion of the seal, heat the effected area gently

with a hair dryer genrly see

(fig 12)

with smooth strokes of the hair dryer, then when still warm pull the effected

area back into its original position, this process may have to be repeated until the seal is completely back to its

original condition.

Fig.12

2>. If the ice has damage the fan it will need to be replaced see.

(Fig.10)

○

In some older models, the electrical connector of the fan wires is fixed under the evaporator, and water

from evaporator may drip onto this junction box ,this may effect the electrical connection ,causing the fan

to stop. Which in turn causes surface freezing.

1>. Remove the air duct board see

(Fig.1, Fig.2 ,Fig.3,Fig.4 & Fig.5)

, remove the cable clip securing

screws(A), and remove the cable clip see

(Fig.13)

2>. Cut off the both connectors see.

(Fig.13.1)

3>. Strip the ends of the wires about 12mm and re-connect then

.

Ensure this electrical joint is sealed against future water damage, and is electrically safe

(Fig.14)