13

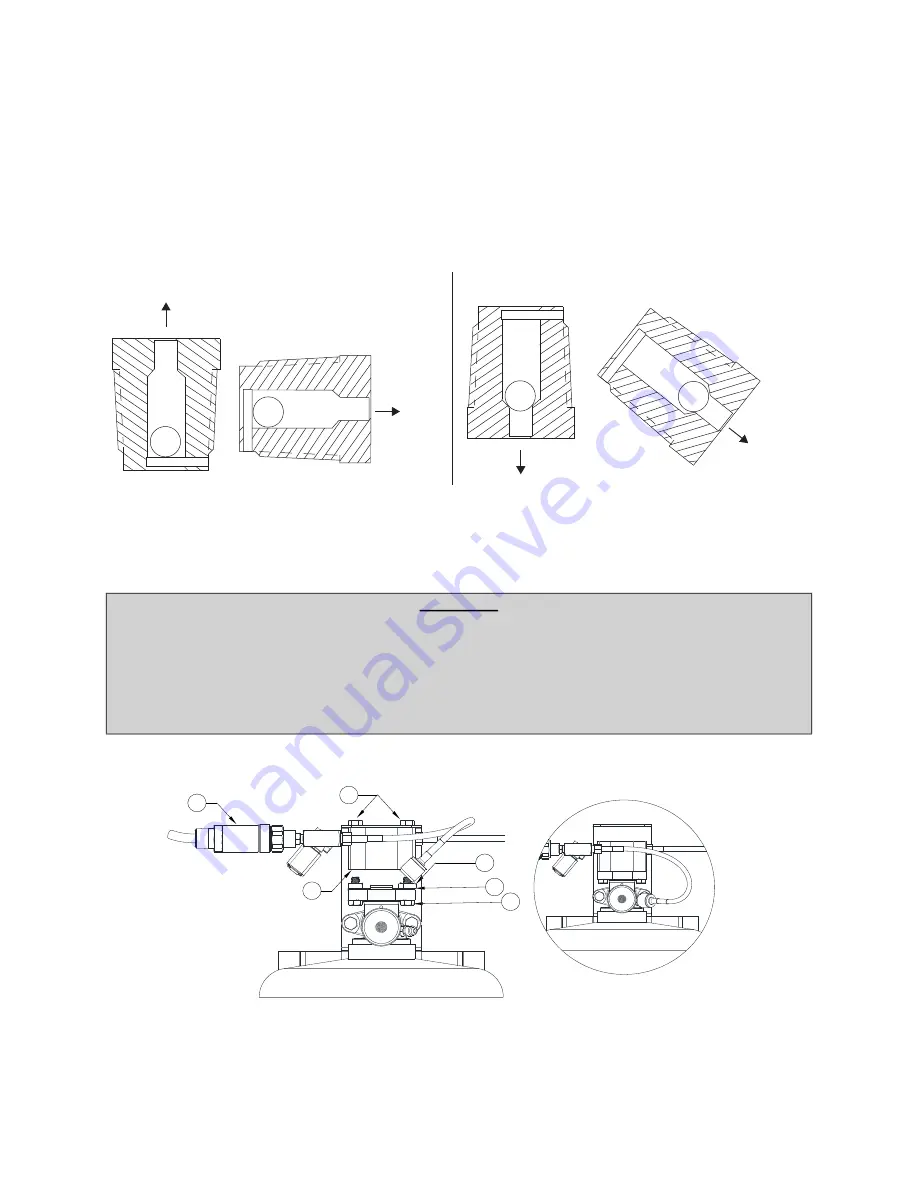

Vent Plug

The vent plug is factory-installed in the agent distribution supply line. The vent plug can be installed in the

outlet or run off a tee in the distribution pipe network. The vent plug must be installed from a horizontal to

vertically up position to ensure that it will open upon slight rises in pipe system pressure (e.g., due to

ambient temperature fluctuation).

The vent must not be installed below the horizontal position (e.g., pointing downward), or it may fail to

relieve pressure when required. One vent plug is required for each distribution pipe network.

Figure 14 - Vent Plug Orientation

NOTE: When improperly installed, gravity pulls the vent plug closed, preventing small pressure

buildups from escaping.

Primary and Secondary Actuator Installation

Figure 15 - PAK in Ship/Test and Installed Positions

WARNING!

Do not complete PAK or secondary valve actuator installation until system test and

commissioning are complete. The cylinder bracket includes a platform for securing a primary

actuator kit or secondary valve actuator during shipping and maintenance procedures. The

system actuators must be in the ship/test position for all commissioning and test procedures.

Testing with actuators in place will result in discharge of the agent cylinders.

Refer to “Start-up/Test Procedure” on page 60 for the testing and commissioning procedure.

Correct Orientation

Incorrect Orientation

Direction of

Pressure Flow

Direction of

Pressure Flow

Direction of

Pressure Flow

Direction of

Pressure Flow

1. Shipping Bolts

2. Nut

3. Valve Protection Plate

4. Mounting Bolts

5. Primary Actuator Kit (In Transport Position)

6. Supervisory Pressure Switch

Ship/Test Position

Installed Position

5

1

2

3

4

6

Summary of Contents for EWC

Page 2: ...2 ...