34

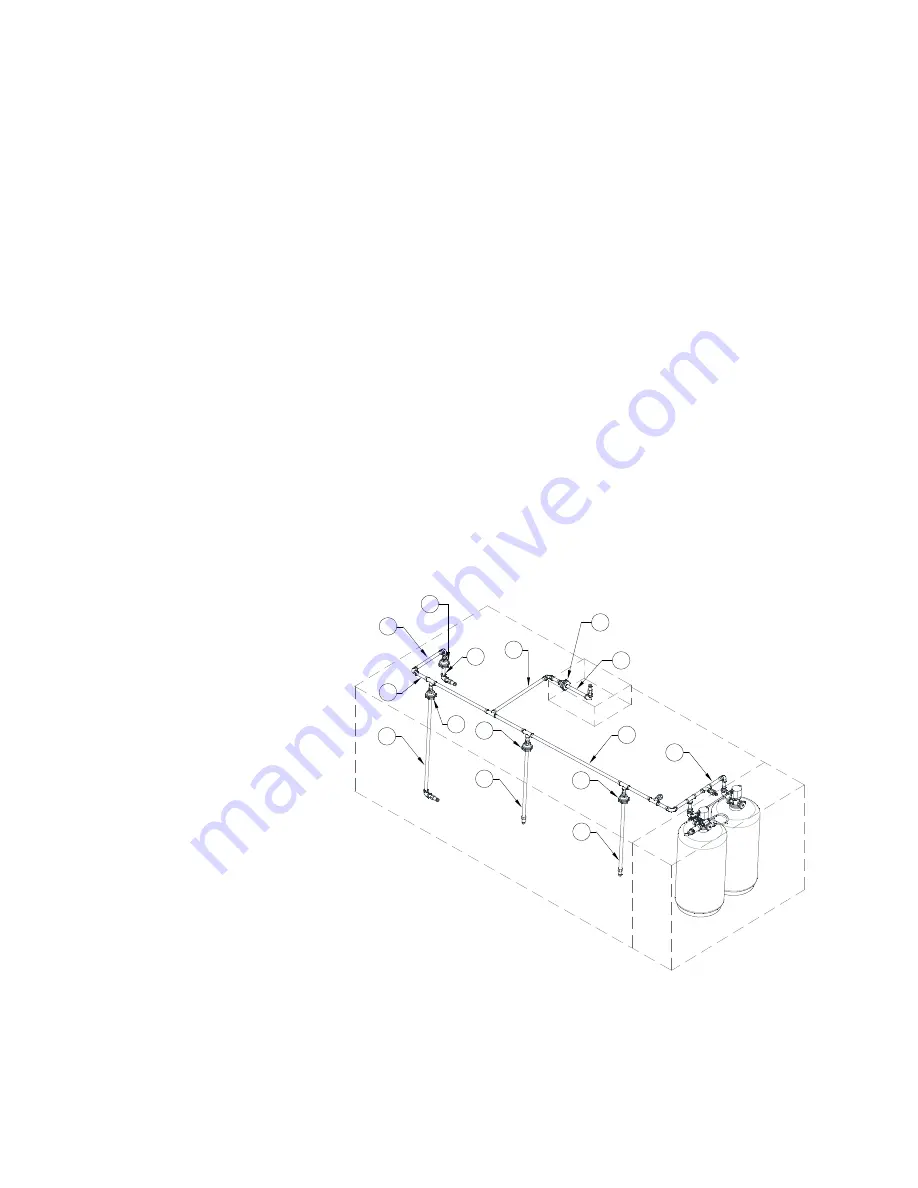

Agent Distribution Piping

The agent distribution piping shall be 3/8” NPT Schedule 40 black iron, chrome-plated or stainless-steel

pipe and fittings. Fittings shall be minimum class 150. The pipe for the nozzle drops cannot be sleeved in

steel but can be made from polished stainless steel, or polished chrome-plated black iron.

Galvanize pipe or fittings must not be used. Pipe thread or compound shall not be used.

Distribution piping can be run in single cylinder or dual cylinder, manifold configurations. Refer to

for single cylinder configuration details. Refer to

for dual cylinder configuration details.

The distribution network consists of a supply line and all applicable branches depending on the protected

hazards. Branch lines include the plenum branch, duct branch, overlapping nozzle appliance branch (TF1

nozzle), and dedicated nozzle appliance branch (ADP).

The supply line is defined as the run of all pipe and fittings from the tank outlet to the last branch line,

including fittings at the start of all branch lines. All branch lines start at the outlet of the applicable supply

line fitting and do not include the supply tee.

A plenum branch is defined as the run of all pipe and fittings from the supply line tee outlet to the plenum

nozzle(s).

A duct branch is defined as the run of all pipe and fittings from the supply line tee outlet to the duct

nozzle(s).

An overlapping nozzle appliance branch is defined as the run of all pipe and fittings from the supply line tee

outlet to the TF1 nozzle.

A dedicated nozzle appliance branch is defined as the run of all pipe and fittings from the supply line tee

outlet to the ADP nozzle.

Figure 34 - Distribution Piping

1

3

3

2

2

1

2

5

4

4

3

3

6

6

3

1. Duct Branch Line

2. Supply Piping

3. Hood Penetrations

4. Overlapping Branch Line

5. Dedicated Appliance Branch

Line

6. Plenum Branch Line

Summary of Contents for EWC

Page 2: ...2 ...