14

docs.carbide3d.com

support@carbide3d.com

15

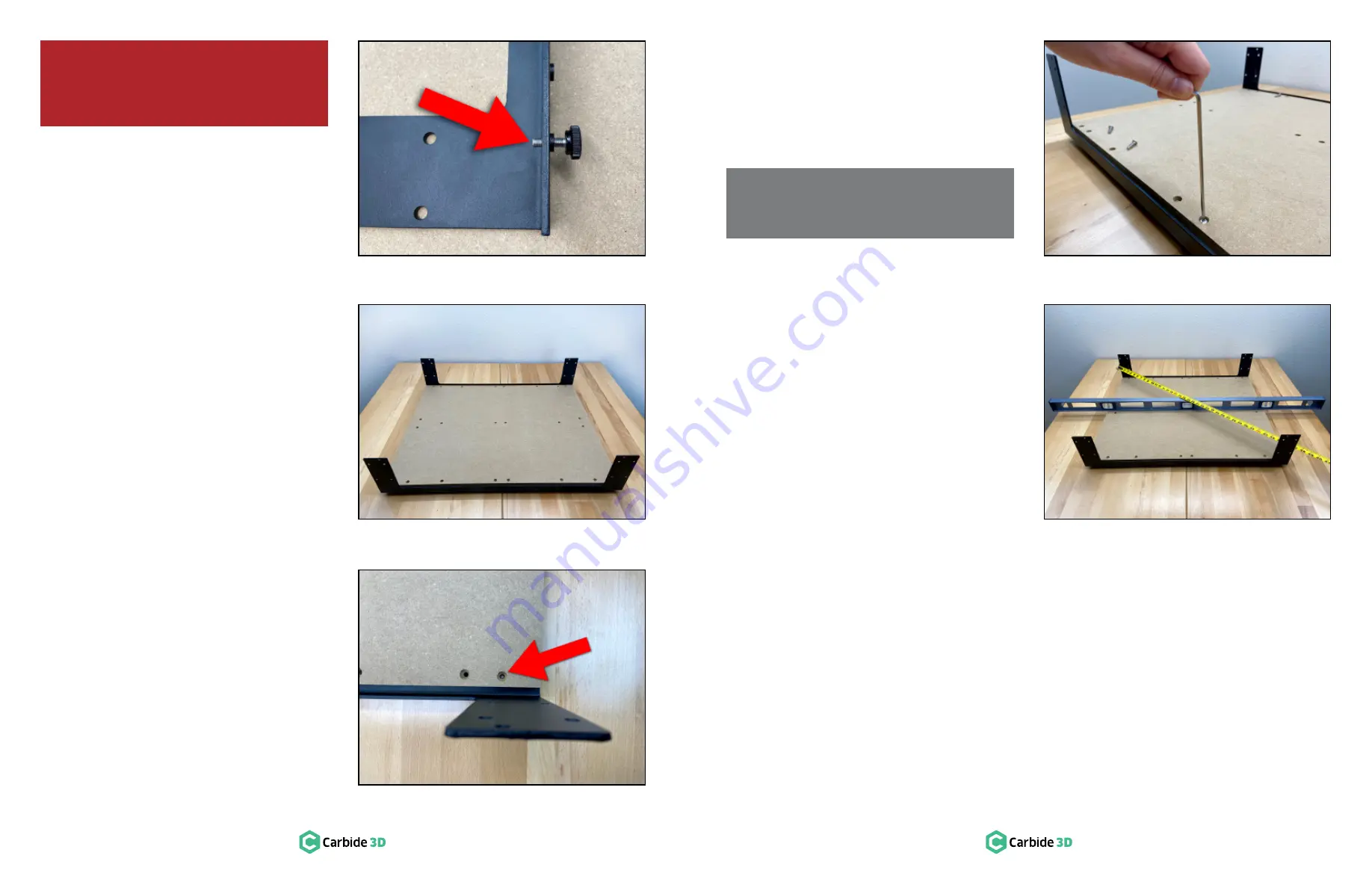

Attach the Adjustable

Leveling Feet

1.

Screw the four (4) adjustable leveling feet

into the outermost PEM nuts at either end of

each endplate. Screw in until there is an equal

portion of thread exposed above and below

the endplate, about 3/16

″

.

See

Figure 2‑4

.

Attach the MDF Baseplate

to Front and Rear

Endplates

1.

Position the MDF baseplate on your

workspace with the countersunk holes facing

up and the longer sides toward the front and

rear. See

Figure 2‑5

.

2.

Slide both endplates, leveling feet down,

into place along the front and rear edges of

the baseplate. The protruding threads of the

leveling feet will insert into the outermost

screw holes from the underside of the

baseplate. See

Figure 2‑5

and

2‑6

.

3.

Use the 3mm hex key and twelve (12)

M5

×

25mm button head cap screws to secure

the MDF baseplate to the two endplates, six

(6) screws for each endplate. See

Figure 2‑7

.

4. Turn the screws until they stop but do not fully

tighten.

Level the Baseframe

Assembly

1.

Adjust the height of each leveling foot to bring

the fully assembled baseframe into level.

Check level front-to-back, side-to-side, and

diagonally. See

Figure 2‑8

.

2.

Optionally, you can check for square by

measuring diagonally across the baseframe

from the outside edges of the endplates. Check

both sides. The machine is square when the

two measurements are equal. Approximates

are acceptable at this stage as the machine is

not fully tightened. A final level and square is

completed in

Step 9: Level and Square

.

NOTE:

We’ll come back and tighten all of the

baseframe screws later on when squaring

the machine.

WARNING:

Do not assemble the Shapeoko

3 on the floor; a large workbench is essential.

The completed dimensions of the Shapeoko 3

are 28.5

″

(X)

×

24

″

(Y)

×

17.5

″

(Z).

Figure 2-5

Figure 2-6

Figure 2-7

Figure 2-4

Figure 2-8