MF58

– 1.06 7

3.0

ABF

O

PERATION

This section describes how to heat the chamber up to temperature,

3.1

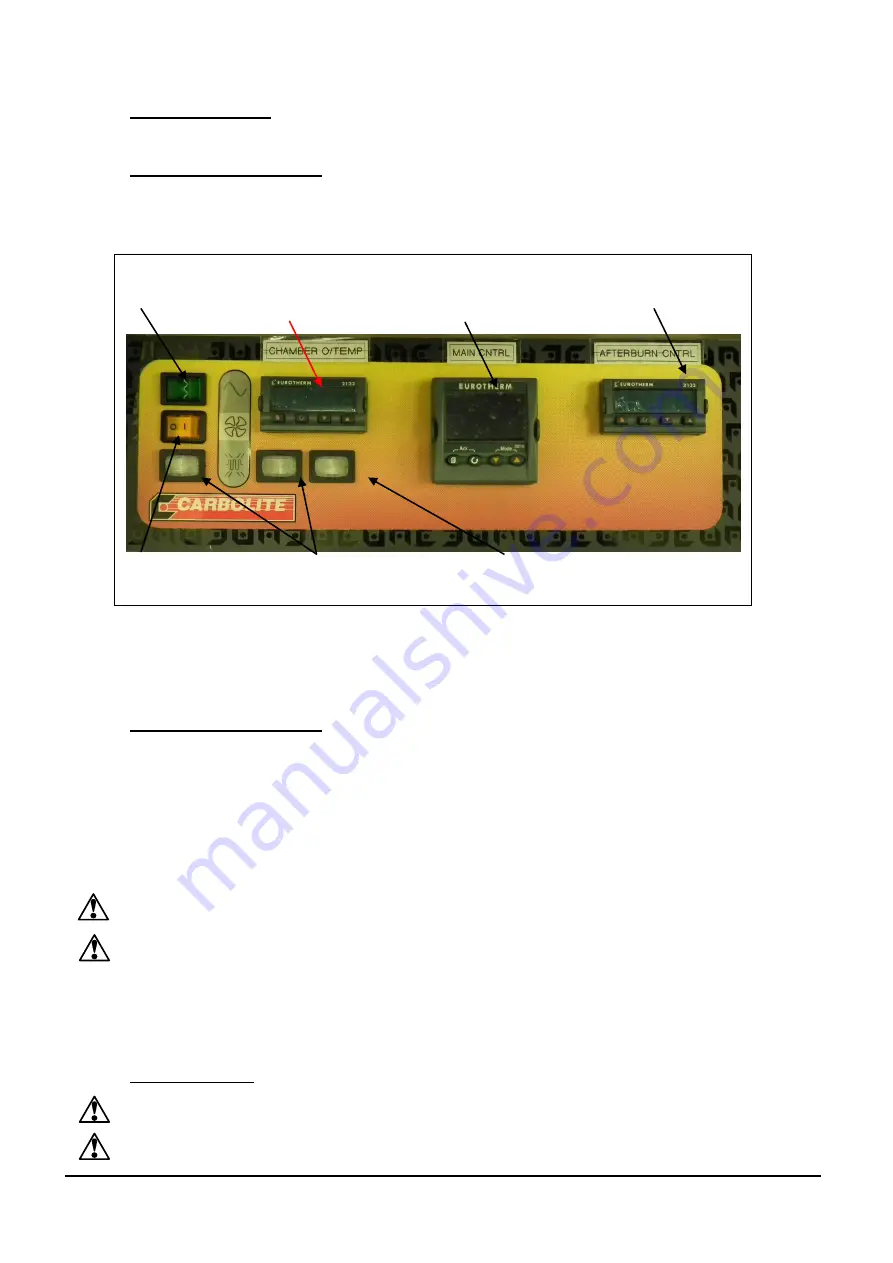

Switches – Control Panel

The main control switches are on the left hand side of the control panel (photo 3.1).

The Instrument Switch cuts off power to the controllers, other devices (including the fan) and

heating circuit contactors.

3.2

General Operating Notes

Heating element life is shortened by use at temperatures close to maximum. Do not leave the

ABF at high temperature when not required. The maximum temperature for the main chamber is

800°C , and for the after burner 950°C.

Light weight ceramic fibre insulation can easily be marked by accidental contact. Some fine

cracks may be visible on the surface of the insulation, or may develop in the surface of the

chamber due to the progressive shrinkage of the insulation materials. Cracks are not usually

detrimental to the functioning or the safety of the furnace.

The chimney and extraction ducting should always be correctly fitted and unobstructed: see

sections 2.3 & 2.4.

See sections 4.1 and 4.2 for information about maintenance.

The product has been design for ashing items that containing no more than 40g of carbon.

Baskets are provided with a loading handle. These can be used to load and unload the items

being ashed. Make sure you have a safe surface, which must not be inflammable, available to

place the basket when unloading.

3.1

Operator Safety

The ABF incorporates a safety switch which interrupts the heating element circuit when the door

is opened.

Wear appropriate safety clothing: gloves, a mask and safety glasses are recommended.

Photo 3.1

extraction fan

switch

Instrument switch

main chamber

heater lamps

afterburner

controller

main chamber

temperature

controller

afterburner

heater lamp

main chamber

over temperature

controller

Summary of Contents for ABF 8/28

Page 14: ...14 MF58 1 06 ...

Page 15: ...MF58 1 06 15 ...