1700-1800° Tube

Insulation Replacement

After any replacement of insulation material, run the furnace at 1500°C to burn off volatile matter.

Do this is a well ventilated area, without the work tube in place.

5.7

Element Installation & Replacement

Safety Warning – Molybdenum Disilicide elements.

The elements form a glazed surface when heated. Internal stresses can form

through heating and cooling which render the glaze fragile. The glaze can

sometimes splinter into a shower of sharp particles when handled. Always wear eye

protection when handling the elements.

Handle the heating elements with extreme care as they are very fragile. Also, avoid touching the

heating surface (the thin part of the element).

Replacement:

Note the length of element above the fixing clamps before starting. Remove the

aluminium braids and clips. Remove the clamp, which has a screw fixing. Lift out the old element

and insulation piece (element block): handle the insulation piece with care as it is fragile.

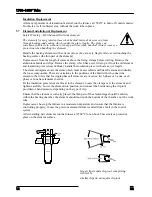

The element diagram shows the items which must be assembled and fitted. Examine and identify

the loose components. There are variations in the positions of the braids which connect the

elements: the rule is that for single phase all elements are in series; for 3-phase or 3-zone, each

phase or zone has elements in series.

Fit the insulation piece (element block) to the element. Locate the clamps over the element, and

tighten carefully. Lower the element into position, and connect the braids using the clip tool

provided or hand pressure, depending on the type of clip.

Ensure that the element is correctly placed: the thin part of the element legs should be entirely

within the heating chamber; the element should not touch the bottom of the chamber, nor the work

tube.

Replacement:

heat up the furnace to a moderate temperature and ensure that the furnace is

controlling properly, in case the previous element failure resulted from a fault in the control

system.

After installing new elements run the furnace at 1500°C for an hour. This creates a protective

glaze on the element surface.

12

MF32

larger clips require clip tool, comprising

two levers

smaller clips do no require clip tool

Summary of Contents for CTF

Page 9: ...1700 1800 Tube 4 0 MF32 9 ...