1700-1800° Tube

General Operating Advice

Heating element life is shortened by use at temperatures close to maximum. Do not leave the

furnace at high temperature when not required. The maximum temperature is shown on the

furnace rating label and on the back page of this manual. The furnace can be cycled between room

temperature and maximum without a detrimental effect on element life - but see the notes on tube

life.

On first installing the elements, and on subsequent element replacement, run the furnace at

1500°C for an hour to create a protective glaze on the element surface.

The furnace elements are very susceptible to mechanical shock. Take great care when moving the

furnace.

3.5

Operator Safety

Ceramic materials used in furnace manufacture can become conduction at high temperature.

Avoid using conductive tools within the work tube without first isolating the elements. The

elements are isolated (via a contactor) when the instrument switch is off.

If a metal work tube is used, it must be earthed (grounded). Note that the furnace temperature

should be limited if a metal tube is used.

Ensure that there are no inflammable objects placed in such a way that the work tube could break

and fall on them.

3.6 Tube Life

A ceramic work tube may crack if workpieces are inserted

too quickly or at temperatures below 900°C (when the tube

is more brittle). Large pieces should also be heated slowly

to ensure that large temperature differences do not arise.

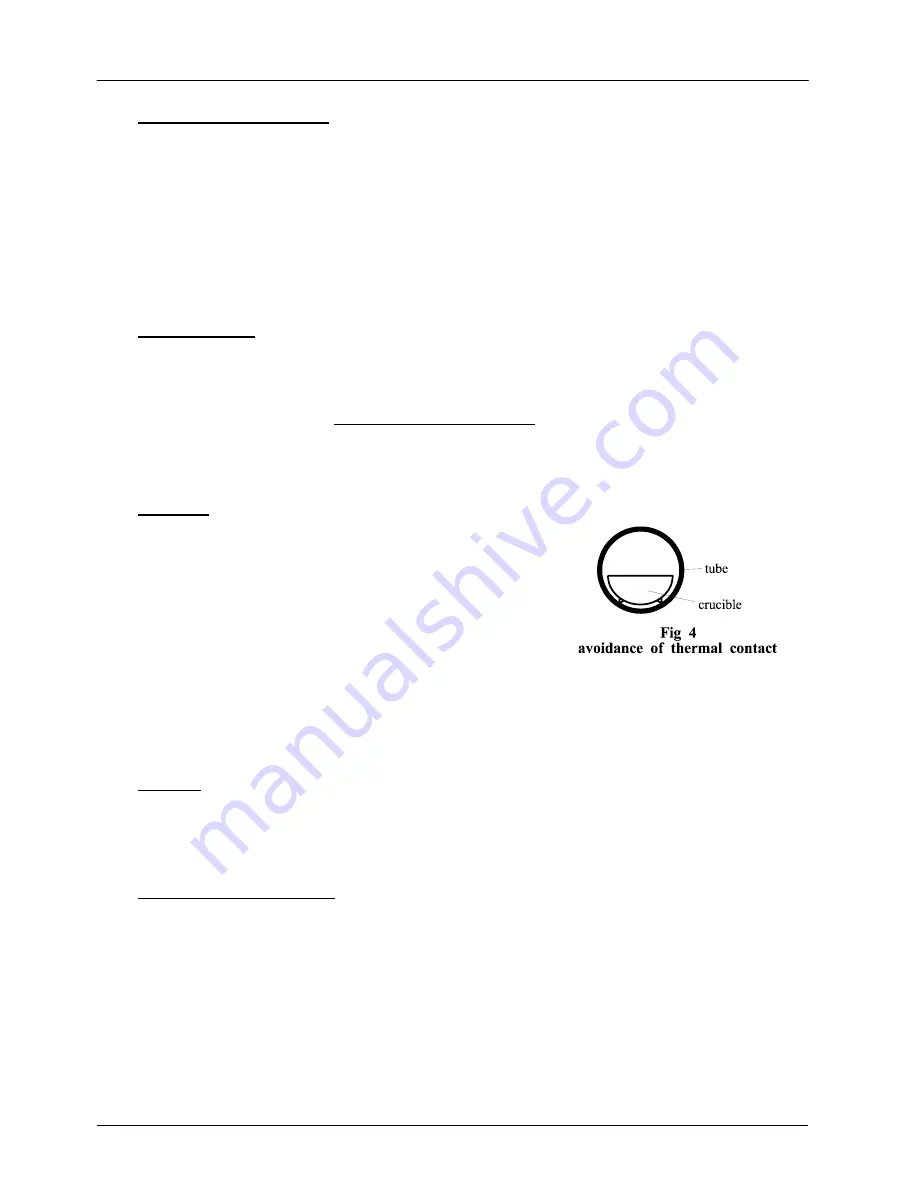

Poor thermal contact should be encouraged between the

workpiece and the tube; crucibles or boats should be of

low thermal mass and should have feet to reduce the

contact with the tube (fig. 4).

Avoid metal directly touching the work tube - see the safety warning above.

Do not set too high a heating rate. Large diameter tubes are more susceptible to thermal shock

than smaller. A general rule for maximum heating rate is 400/internal diameter (°C/min); for

75mm i/d tubes this comes to 5°C per minute. The controller can be set to limit the heating rate.

3.7

Pressure

Work tubes are not able to accept high internal pressure. When gas seals or similar fittings are in

use, the gas pressure should be restricted to a maximum of 0.2 bar (3 psi). A pressure of about half

of that should normally be sufficient to achieve the desired flow rate. The customer must ensure

that the exhaust path from the tube is not blocked, so that excess pressure does not occur.

3.8 Thermocouples - Warnings

(1)

The output from 1700-1800°C thermocouples when used regularly at temperatures greater than

1650°C can deteriorate and decrease with age.

Customers are advised periodically to check the thermocouple output, either by a calibration test,

or by comparing the output with a new reference thermocouple which has been subjected to high

temperatures for a minimum length of time.

Failure to check the thermocouple may result in overheating of the work and the furnace.

(2)

The thermocouples fitted to these models give very low outputs below about 600°C, and do not

give accurate readings at low temperatures. The furnaces are not intended to be operated below

600°C.

8

MF32

Summary of Contents for CTF

Page 9: ...1700 1800 Tube 4 0 MF32 9 ...