B-7 OPERATION B-7

OPERATING STEPS

WELDING IN TIG MODE

1 Connect the TIG torch and cable Twist-Mate quick

connect plug to the Electrode/Gas

output

receptacle. This receptacle also contains an integral

gas connection for the torch. Connect the work

clamp to the work piece.

2 Set the TIG/MMA/CUT switch to "TIG".

3 Set the AC/DC Switch to DC for welding steel or

stainless steel; or to AC for welding aluminum.

4 Connect the arc start switch

(

or

Adjustable foot

control

)to the Remote Control Connector.

5 Turn on the cylinder gas valve and adjust the flow

regulator to obtain desired flow.

6 Turn the power switch to "ON".

7 Preset the Output Control on the control panel to

the maximum desired amps, as read on the digital

meter.

8 Depress the

Adjustable foot control

to energize

the torch and establish an arc with the work piece.

The digital meter reads the actual amps while

welding.

NOTE:

When the TIG/MMA switch is set to "TIG", depressing

the remote control will start a 0.5 second gas pre-flow before

energizing the TIG torch. When the remote control is released

the TIG torch is de-energized and gas flow will continue for the

time set by the Post Flow Time control. When the polarity

switch is set to DC, the TIG Arc Starter will turn on and off

automatically to start and stabilize the arc. In AC the TIG Arc

Starter will turn on with the output and remain on continuously

until the remote control is released.

WELDING POLARITY

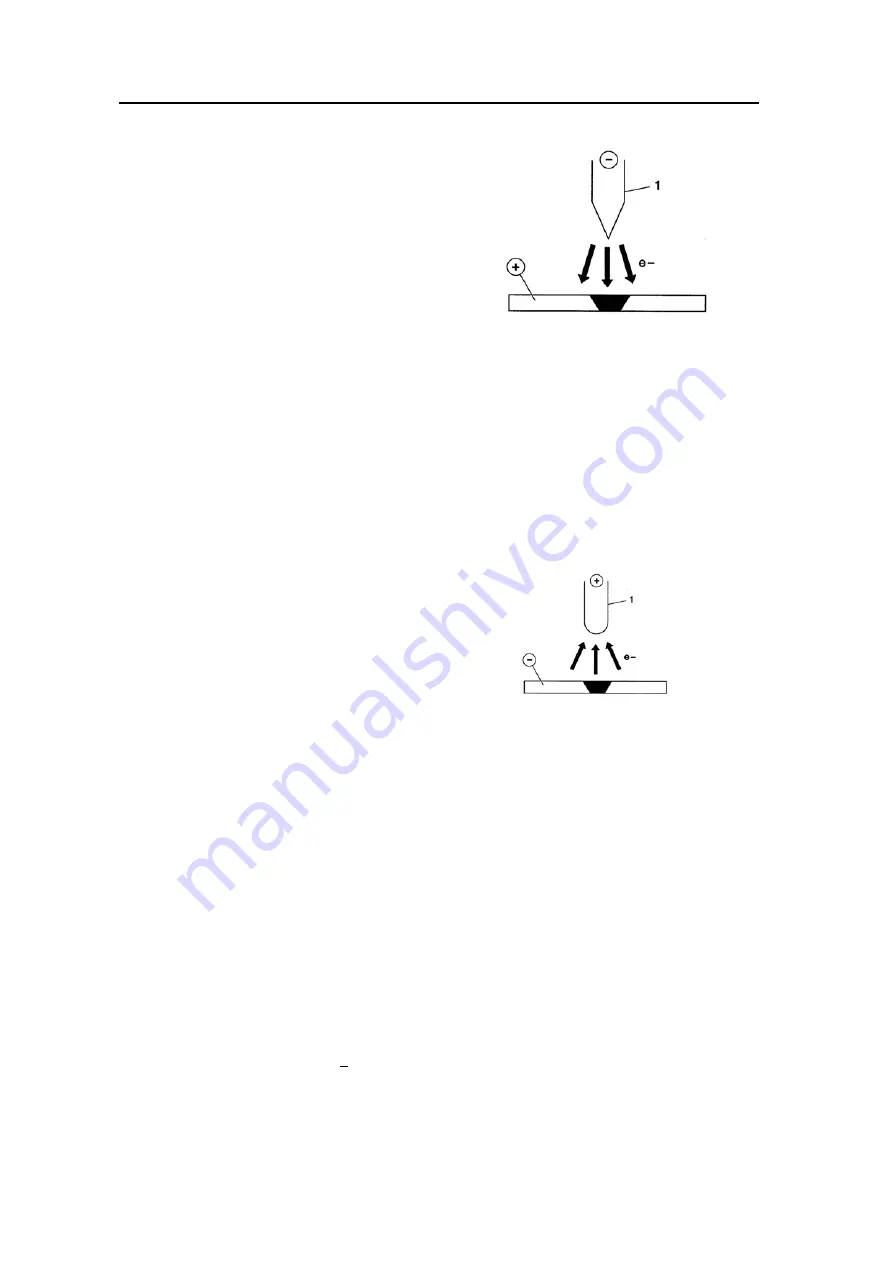

DC Electrode Negative Polarity (Direct Current

Straight Polarity) (see FIGURE B.4)

While Welding, there is a continuous flow of

electrons from the electrode to the workpiece.

This is the most used polarity, ensuring limited wear

of the electrode, since the majority of the heat

concentrates on the anode (workpiece). Narrow and

deep welds are obtained with high travel speeds.

Most materials, with the exception of aluminum and

magnesium, are welded with this polarity.

FIGURE B.4

DC Electrode Positive Polarity. (Direct Current

Reverse Polarity)

(see Figure B.5)

In this case, there is a continuous flow of electrons

from the workpiece to the electrode. The reverse

polarity is used for welding alloys covered with a

layer of refractory oxide.

With this polarity the electrode functions as anode

and is subjected to a high degree of heat; the

workpiece is bombardment by positive ions sent

from the electrode which break the surface oxide.

In Electrode Positive Polarity, high currents cannot

be used, since they would cause an excessive wear

of the electrode.

FIGURE B.5

D.C.-Pulsed TIG

(see Figure B-6)

The use of pulsed direct current allows better

control of the weld pool during certain operating

conditions.

When compared with traditional TIG welding

performed at the same average current, pulsed

welding results in a smaller heat affected zone

which results in fewer deformations and reduced

chance of cracking and gas entrapment.

Summary of Contents for PowerMaster256

Page 28: ...B 13 OPERATION B 13 ...

Page 29: ...B 14 OPERATION B 14 ...

Page 30: ...B 15 OPERATION B 15 ...

Page 34: ...B 19 OPERATION B 19 ...

Page 35: ...B 20 OPERATION B 20 ...

Page 36: ...B 21 OPERATION B 21 ...

Page 37: ...B 22 OPERATION B 22 ...