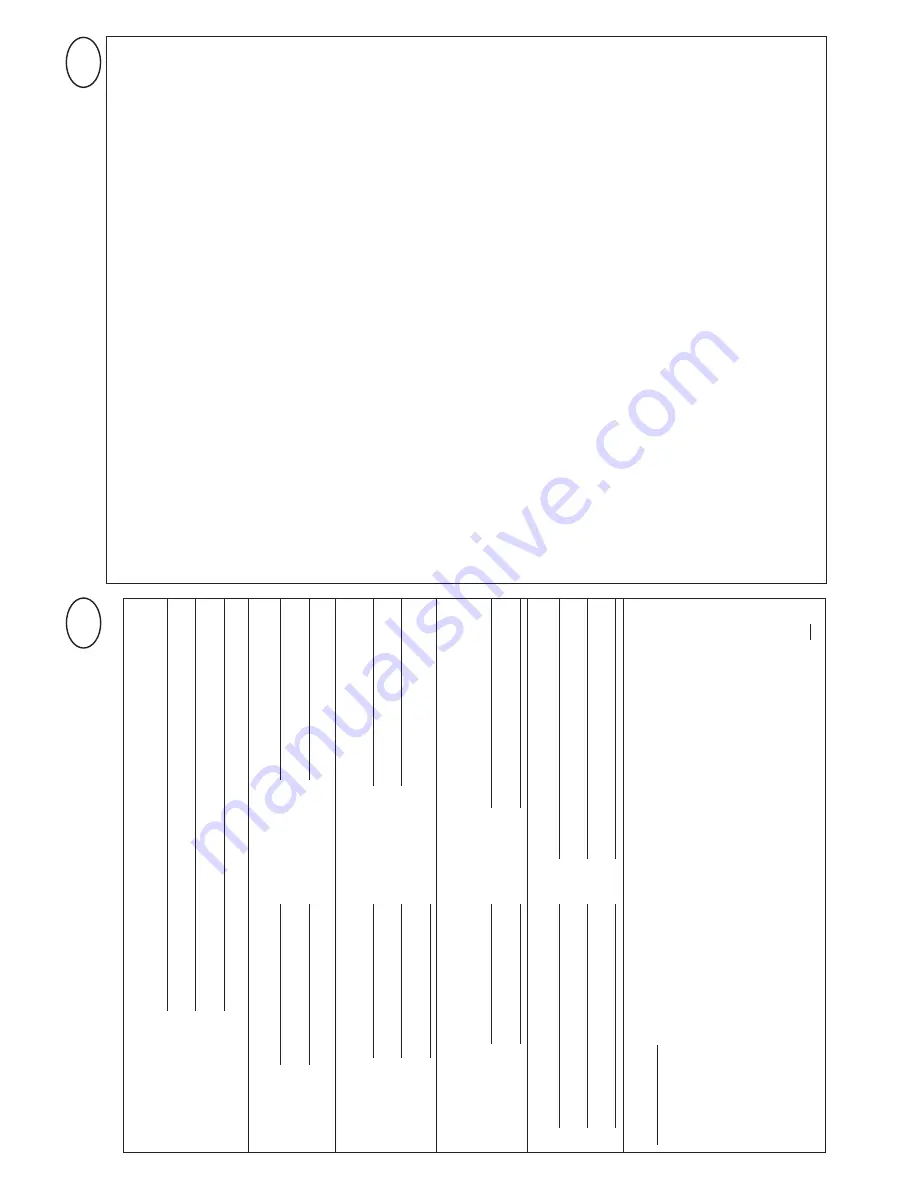

Inspection

and

test

log

book

for

the

door

system

T

esting

of

door

system

Owner

/

operator

of

the

system:

Location

of

door

system:

Operator

data:

Operator

type:

Manufacturer:

Date

of

manufacture:

Operating

mode:

Door

data:

T

ype:

Serial

no.:

Door

dimensions:

Y

ear

of

construction:

Leaf

weight:

Installation

and

initial

operation

Company

,

installer:

Initial

operation

on:

Name,

installer:

Signature:

Other

details

Subsequent

alterations

Retain

these

installation,

operating

and

maintenance

instructions

for

the

full

duration

of

the

operator

’s

service

life!

GB

Retain

these

installation,

operating

and

maintenance

instructions

for

the

full

duration

of

the

operator

’s

service

life!

GB

General

information

When

being

put

into

service

power-

operated

doors

must

be

inspected

and

maintained

by

correspondingly

qualified

persons

(persons

with

suitable

training

and

qualifications

based

on

knowledge

and

experience)

at

intervals

as

specified

in

the

manufacturer

's

maintenance

instructions

and,

if

necessary

,

also

in

accordance

with

any

special

national

regulations

(e.g.

BGR

232

"Guidelines

for

P

ower-operated

Windows,

Doors

and

Gates").

All

inspections

and

maintenance

carried

out

must

be

documented

in

the

inspection

log

book

provided.

It

must

be

kept

safe

by

the

owner-

operator

,

together

with

the

documentation

on

the

door

system,

throughout

the

operator's

entire

service

life

and

must

be

filled

out

in

full

and

handed

over

to

the

owner-

operator

by

the

installer

at

the

latest

at

the

time

of

putting

into

service.

(W

e

also

recommend

this

for

manually

operated

doors.)

It

is

absolutely

imperative

that

the

guidelines

provided

in

the

documentation

accompanying

the

door

system

(Installation,

Operating

and

Maintenance

Instructions

etc.)

are

adhered

to.

The

m

anufacturer's

guarantee

becomes

null

and

void

in

the

event

that

inspection

/

maintenance

has

not

been

properly

carried

out.

Alterations

to

the

door

system

(in

as

far

as

permitted)

must

also

be

documented.

Caution:

An

inspection

is

the

same

as

maintenance!

not

Check

list

of

door

system

(Document

the

equipment

present

at

the

time

of

initial

operation

by

ticking

off)

Equipment

present

Features

to

be

tested

applicable

Remark

1.0

Door

1.1

________________________

Manual

operation

of

the

door

Smooth

running

1.2

/

________________________

Fastenings

/

connections

State

Seat

1.3

/

________________________

Pivots

/

joints

State

Lubrication

1.4

/

________________________

T

rack

rollers

/

track

roller

holders

State

Lubrication

1.5

/

________________________

Seals

/

sliding

contact

strips

State

Seat

1.6

/

________________________

Door

frame

/

Door

guide

Alignment

Fastening

1.7

/

________________________

Door

leaf

Alignment

State

2.0

W

eight

counterbalance

/

safe

opening

2.1

/

/

________________________

Springs

State

Seat

Setting

2.1.1

Steel

tape

________________________

State

2.1.2

/

________________________

Spring

safety

device

State

Data

plate

2.1.3

/

________________________

Safety

elements

State

Seat

(spring

connector

,...)

2.2

/

________________________

Wire

cables

State

Seat

2.2.1

/

________________________

Cable

fastening

State

Seat

2.2.2

________________________

Cable

drums

2

safety

windings

2.3

________________________

Anti-fall

safeguard

State

2.4

________________________

Concentricity

of

T

-shaft

State

3.0

Operator

/

controls

3.1

/

sliding

rail

/

bracket

________________________

Operator

/

State

Fastening

3.2

________________________

Electrical

cables

/

connections

State

3.3

/

________________________

Emergency

release

State

Function

3.4

/

________________________

Control

devices,

State

Function

push-button

/

hand

transmitter

3.5

Limit

stop

/

Position

________________________

State

4.0

Safeguarding

of

crush

and

shearing

zones

4.1

________________________

Force

limit

Stops

and

reverses

4.2

________________________

Safeguards

to

prevent

persons

Door

leaf

stops

at

20

kg

from

being

lifted

up

by

the

door

4.3

________________________

Site

conditions

Safety

distances

5.0

Other

devices

5.1

/

________________________

Latching

/

lock

State

Function

5.2

/

________________________

Wicket

door

Function

State

5.2.1

/

________________________

Wicket

door

contact

Function

State

5.2.2

/

________________________

Door

closer

Function

State

5.3

/

________________________

T

raf

fic

light

control

Function

State

5.4

/

________________________

Photocells

Function

State

5.5

/

________________________

Safety

edge

Function

State

6.0

Documentation

of

the

operator

/

owner

6.1

/

_______________________

Data

plate

/

C

E

marking

complete

readable

6.2

/

________________________

Door

system

's

declaration

complete

readable

of

conformity

6.3

/

________________________

Installation,

Operating

and

complete

readable

Maintenance

Instructions

Summary of Contents for DC 650 T

Page 1: ...DC 650 T DC 800 T WN 923013 04 6 50 05 13...

Page 3: ...11 11 iso 20 10 6 3 x 16 5a a X a X 10 10 13 1a 1 8 x 16 13 2 4 17 5b 1 13 2 3e...

Page 4: ...13 8 7 11 11 4 12 max 45 13 8 9 9 13 10 a b a 7 12...

Page 6: ...A a C B D 14 3 sec 14 5x 5x 19b 19a 17c 17b 18b 16b 16a 17a 18a 15a 15b 15c F F 400N 50mm 20...