16

- make sure that the space between the bottom of the gate and the

pavement never exceeds

30 mm

throughout the entire opening angle

of the gate.

• The surface of the gate must not feature openings which allow a person’s

hand or foot to pass through.

• Check the exact positioning of the pivots, and their good working order

(the upper and lower hinges/pivots must be aligned on the same axis).

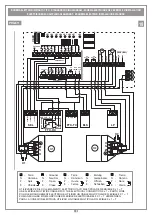

• Work out the run of the cables according to the command and control

devices fitted and make sure the system conforms to the local standard

and regulations in force (see installation example fig. 1 pag. 2).

• Check that the appliance is suitable for the size, weight and duty cycle

of the gate to which it is to be applied (see duty cycle on page 28)

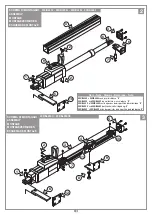

FITTING THE UNITS 200/BL203- BL203L

The unit may be positioned either to the right or to the left of the pas-

sageway.

To install the unit correctly carry out the following procedure carefully.

• Move the gate/s to the closed position.

• Select the type of opening required (fig. 8, 9 pag. 5).

• Fasten the rear mooring bracket to the column (fig. 13 pag. 7), taking

into account the measurements "

A

" and "

B

", after having checked the

position of the gate hinge with respect to the column (measurement

"

C

" fig. 8, 9 page 5) according to the type of opening required.

• Fix the arm to the rear mooring bracket "

5

" using the retaining pin "

1

"

(fig. 2 pag. 3) and the front bracket "

6

" using the pin "

7

".

• Extend the arm manually until it reaches

5 mm

from the end of the

travel distance.

ATTENTION

! The centre distance between the front mooring

bracket "

2

" and the rear mooring bracket "

1

" must never exceed

1000 mm

for the

BL203

and

1345 mm

for the

BL203L

(see figures

8-9 on page 5)

• Move the arm to its normal operating position, rest the head against

the gate and mark the position of the front bracket "

6

".

Note: Make sure the operator is perfectly level (using a spirit level) and

then fix the front bracket to the gate (fig. 14 pag. 7).

• The front bracket may be fixed in the following positions:

- on the gate frame or on a horizontal cross beam,

- if this is not possible, fix a reinforcing plate to the gate structure and

then fasten the front bracket onto the reinforcing plate.

• Insert the arm in the front bracket "

6

", insert the retaining pin "

7

" and

fasten down using the supplied C-clips (fig. 2 pag. 3).

• Install the protective carter by fastening the 4 screws on the geared

motor (pos. 2 fig. 2) and position the plastic protective cap (pos. 4 fig.

2).

• With the motor released move it manually to the fully open position and

check that all the components work correctly.

• If you are using

200/BL203L

with a gate from

2

to

4

metres in width an

electric locking device must be fitted to ensure that the gate is blocked

when it is closed.

FITTING THE UNITS 200/BL352 - 200/BL452

The unit may be positioned either to the right or to the left of the passage-

way. To install the unit correctly carry out the following procedure carefully.

• Move the gate/s to the closed position.

• Select the type of opening required (fig. 8 pag. 5).

• Fasten the rear mooring bracket to the column (fig. 13 pag. 7), taking

into account the measurements "

A

" and "

B

", after having checked the

position of the gate hinge with respect to the column (measurement

"

C

" fig. 8 page 5) according to the type of opening required.

ATTENTION!

The motor must be installed on the

gate with the humidity drain holes "

A

" facing

downwards (see drawing)

• Fix the arm to the rear mooring bracket "

5

" using the retaining pin "

1

"

(fig. 2 pag. 3) and the front bracket "

6

" using the pin "

7

".

• Extend the arm manually until it reaches

5mm

from the end of the travel

distance.

ATTENTION!

The centre distance between the front mooring

bracket "

2

" and the rear mooring bracket "

1

" must never exceed

1020

mm for the

BL352

and

BL452

(see figure 8 on page 5)

• Move the arm to its normal operating position, rest the head against

the gate and mark the position of the front bracket "

6

".

Note: Make sure the operator is perfectly level (using a spirit level) and

then fix the front bracket to the gate (fig. 14 pag. 7).

• The front bracket may be fixed in the following positions:

- on the gate frame or on a horizontal cross beam;

- if this is not possible, fix a reinforcing plate to the gate structure and

then fasten the front bracket onto the reinforcing plate.

• Insert the arm in the front bracket "

6

", insert the retaining pin "

7

" and

fasten down using the supplied C-clips (fig. 2 pag. 3).

• Install the protective carter by fastening the 4 screws on the geared

motor (pos. 2 fig. 2) and position the plastic protective cap (pos. 4 fig.

2).

• Extend the arm manually until it reaches

5mm

from the end of the travel

distance.

• Mount the electric locking device (locks the gate in the closed position).

FITTING THE UNIT 200/BL203C - 200/BL203CE

The unit may be positioned either to the right or to the left of the pas-

sageway.

• Move the gate/s to the closed position.

• Select the type of opening required (fig. 10 pag. 5).

• Fasten the rear mooring bracket to the column (fig. 13 pag. 7), taking

into account the measurements "

A

" and "

B

", after having checked the

position of the gate hinge with respect to the column (measurement

"

C

" fig. 10 page 5) according to the type of opening required.

Note:

if the gate brackets are to be pre-installed (front and rear)

without the presence of the piston, you must also consult the indica-

tions in figure 18.

• Position the protective carter "

3

" (with the scoring facing the gate),

fasten the 4 screws "

2

" positioned on the geared motor (tighten them

well down) and insert the plastic end cap "

5

" using the four supplied

screws (fig. 2 pag. 3).

• Rotate the never ending screw (part. 4 fig. 3) until it reaches

15 mm

from the end of the closing direction travel distance.

• Fix the arm to the rear mooring bracket "

6

" using the retaining pin "

1

"

(fig. 3 pag. 3).

• Move the arm to its normal operating position, rest the head against

the gate and mark the position of the front bracket "

6

".

Note: Make sure the operator is perfectly level (using a spirit level).

- position the front holding bracket (fig. 14 pag. 7)

• The front bracket may be fixed in the following positions:

- on the gate frame or on a horizontal cross beam,

- if this is not possible, fix a reinforcing plate to the gate structure and

then fasten the front bracket onto the reinforcing plate.

• Insert the retaining pin of the never ending screw "

4

" into the front

bracket "

9

" and fasten down using the supplied screw and washer

"

8

" (fig. 3 pag. 3).

• With the motor released move it manually to the fully open position

and check that all the components work correctly.

• If you are using

200/BL203C - 200/BL203CE

with a gate from

1,8

to

3 m

in width an electric locking device must be fitted to ensure that

the gate is blocked when it is closed.

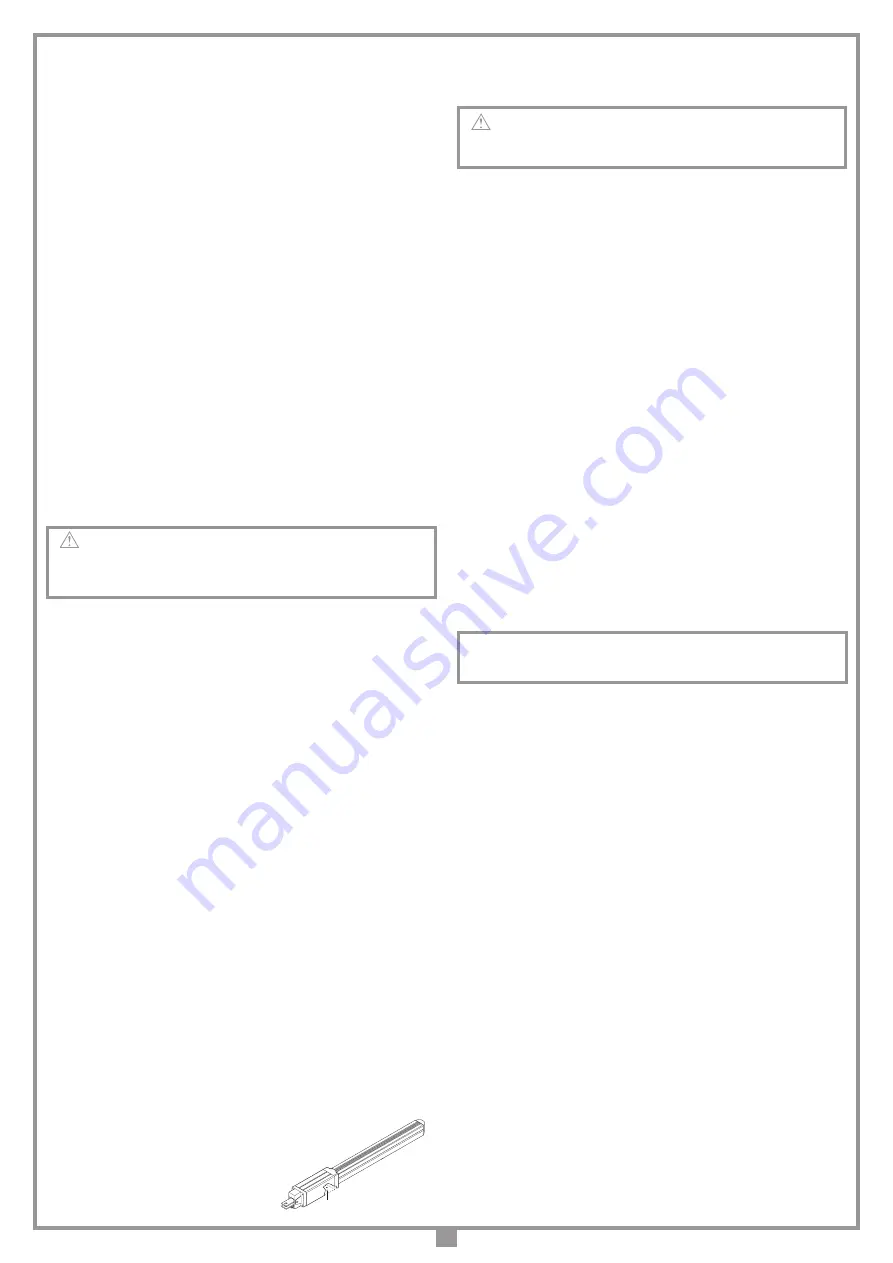

SCALA: 1:2

Prodotti Technocity

BL352

16-11-98

DI0103

Description :

Product Code :

Date :

Drawing number :

P.J.Heath

CARDIN ELETTRONICA S.p.A - 31020 San Vendemiano (TV) Italy - via Raffaello, 36 Tel: 0438/401818 Fax: 0438/401831

Draft :

All rights reserved. Unauthorised copying or use of the information contained in this document is punishable by law

Scarico condensa BL352/452

A