14

Attention!

There is no

230 Vac

contact on any part of the electronic

card: only low voltage safety current is available. In conformity with the

electrical safety standards it is forbidden to connect binding posts

9

and

10

directly to a circuit that receives power greater than

30 Vac/dc

.

Warning!

For the correct operation of the programmer the incorporated

batteries must be in good condition: the programmer will

lose the

position of the door

in case of blackouts when the batteries are flat

the alarm will sound. Check the good working order of the batteries

every six months (see page 19

"Battery check"

).

• After having installed the device,

and before powering up the program-

mer

, release the door (manual release mechanism) and move it manually,

checking that it moves smoothly and has no unusual points of resistance.

• The controlled load output (binding post 15) is aimed at reducing battery

power consumption (if installed) during blackouts; photocells and other

safety devices should be connected to this output.

• When a command is received, via radio or via wire, the electronic program-

mer routes voltage to the

CTRL 24 Vdc

output. It then evaluates the state

of the safety devices and if they are at rest it will activate the motor.

• Connecting devices to the controlled output contact also allows you to

carry out the autotest function (enabled using "TEST FI" and "TEST FS" in

the "OPTIONS" menu) and check that the safety devices are functioning

correctly.

• The presence of the electrical current sensor does not dispense with the

obligation to install photoelectric cells and other safety devices foreseen by

the safety standards in force.

• Before connecting the appliance make sure that the voltage and frequency

rated on the data plate conform to those of the mains supply.

• For the

230 Vac

power supply only use a

2 x 1.5 mm

2

+ cable.

• The cable may only be replaced by qualified technicians.

• An all pole trip switch with at least 3 mm between the contacts must be

installed between the unit and the mains supply.

• Don't use cables with aluminium conductors; don't solder the ends of cables

which are to be inserted into the binding posts; use cables marked

T min

85°C

and resistant to atmospheric agents.

• The terminal wires must be positioned in such a way that both the wire and

the insulating sheath are tightly fastened (a plastic jubilee clip is sufficient).

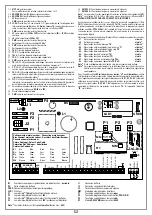

230 Vac POWER SUPPLY CONNECTION

• Connect the control and security device wires.

• Run the mains power supply to the

separate

two-way

terminal board that is already

connected to the transformer.

MOTOR/ENCODER CONNECTION

• You must scrupulously respect the motor connection sequence between the

motors and the programmer. The order of the binding post connections 1 to 6 is

identical on both;

Master motor

1- 2 - power supply motor 1

3-4-5-6 - encoder signal input 1

To change the motor's rotating direction invert

cables 1 and 2

Slave motor

1- 2 - power supply motor 2

To change the motor's rotating direction invert

cables 1 and 2

Preparing the motor connection wires

• Cut the 6-wire cable to the required length according to the installation specifica-

tions; you must remember that in order to avoid current dispersion the maximum

length of the cable must not exceed

20 metres

;

- connect the wires of motor "

M1

" and encoder "

1

" to the main board on the

electronic programmer;

- run the end of the cable to the terminal board on the motor and connect it to the

terminal block through a cable clamp "

PC

".

- insert the wires into the binding posts rigorously respecting the order of the colours

indicated in figure 4 and tighten down the cable clamp "

PC

";

- for the slave motor just connect the 24 V power supply wires (to change the

motor's rotating direction invert cables 1 and 2).

INSTRUCTIONS FOR USE

N

L

IMPORTANT REMARKS

ELECTRONIC PROGRAMMER

• This device has been created to be integrated into the structure of specially

made counterbalanced garage doors.

The geared motor is fitted with screw type attachments that allow it to be fitted

inside metal profiles.

• For garage doors with a width not greater than

4 m

and not more than

2,7

m

in height and for garage doors with a pedestrian access door two

GLi824

motors are required, one "master" motor with an encoder wired to the electronic

programmer and one "slave motor" without encoder connection

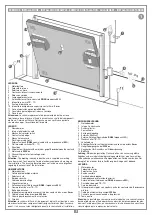

ASSEMBLY PROCEDURE

The unit may be positioned either to the right or to the left of the passageway.

The builder must make sure that the closing system respects the technical indications

supplied by the standards and laws in force:

- Opening and closing direction mechanical stops;

- Safety margins;

- Correct risk analysis at possible crushing points etc.

See:

www.cardin.it - archives - Installation guide and approvals certificates -

The geared motor is fitted with an

Allen key operated manual release

system. The geared motor can

be released by rotating the hex-

agonal socket

clockwise

and the

automatic resetting of the gears

is obtained by rotating the socket

anti-clockwise.

In both cases it is sufficient to

rotate the socket to the end of

its natural course making sure

that you do not force it (about 12

rotations).

Electronic control unit for two dc motor with an incorporated encoder and radio

receiver card, which allows the memorization of

300 user codes

. The "rolling

code" type decoder uses

433.92

MHz series transmitters

S449

.

The motor rotation speed is electronically controlled, starting slowly and increas-

ing in speed; the speed is reduced as it nears the travel limit so as to enable a

controlled smooth stop.

Programming is carried out using the buttons

P1, P2, P3,

and allows you to set the

system, the current sensor and the entire door travel distance.

The logic carries out position control using an encoder. The intervention of the

anticrush/antidrag sensor during the closing and opening stages causes travel

direction inversion.

Collegamenti scheda base

CCi824

17.01.11

DI0557

Description :

Product Code :

Date :

Drawing number :

P.J.Heath

CARDIN ELETTRONICA S.p.A

- 31020 San Vendemiano (TV) Italy - via Raffaello, 36 Tel: 0438/401818 Fax: 0438/401831

Draft :

All rights reserved. Unauthorised copying or use of the information contained in this document is punishable by law

CENTRALINA 2 MOTORE CC CON ENCODER

3

4

5

6

7

1

2

Bl Gr Gy Yw Wh

M

ENCODER

Rd Bk

PC

GLi824 - M1

SEL

1

3

2

24V 12V 0

C

1

6

5

4

3

2

NA

NC

NC

C

NA

FTC-RX

1

3

2

24V

12V

0

FTC-TX

2

1

TB

2

1

LP

1

2

LS

2

1

CSP

CTRL 24Vdc

CMN

CMN

TD (N.O)

CMN

TC (N.O)

TA

L (N.O)

LP

LS

OUT 24Vdc

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

LC/CH2

L2

CSER

31

30

29

CM

N

EMRG 1

EMRG 2

Bl

Blu

Blue

Bleu

Blau

Azul

Gr

Verde

Green

Vert

Grün

Verde

Gy

Grigio

Grey

Gris

Grau

Gris

Yw

Giallo

Yellow

Jaune

Gelb

Amarillo

Wh

Bianco

White

Blanc

Weiss

Blanco

Collegamento motore/encoder - Connecting motor/encoder

Branchement moteur/encodeur - Anschluss der Motor/Encoder

Conexionado motor/encoder

8

4

5

6

7

1

2

Yw Wh

Gy

Gr

Bl

ENCODER

CMN

LCK

CMN

TA

(N.O)

F1

10

10

4A

4A

F3

F2

10

10

F4

4A

4A

J2

J1

R1

MM

27

28

CS 1392A

DC 0449

LCD1

L1

P1

P2

P3

ANS400

MM

24LC16

FI (N.C/8.2 kΩ)

TB (N.C/8.2 kΩ)

FS (N.C/8.2 kΩ)

CP (N.C/8.2 kΩ)

B1

BC

T B

F S

F I

C P

S1

S3

S2

S4

J3

Enable

Disable

1 2 3

J3

Pos.1 Pos.2

1 2 3

LCK

Colore Cablaggi - Colour Code Cable

Coloration Des Câblages - Kabelfarben

Coloración Cableados

Bk

Rd

MOT

1

2

M

Rd Bk

PC

GLi824 - M2

3

Rd

Bk

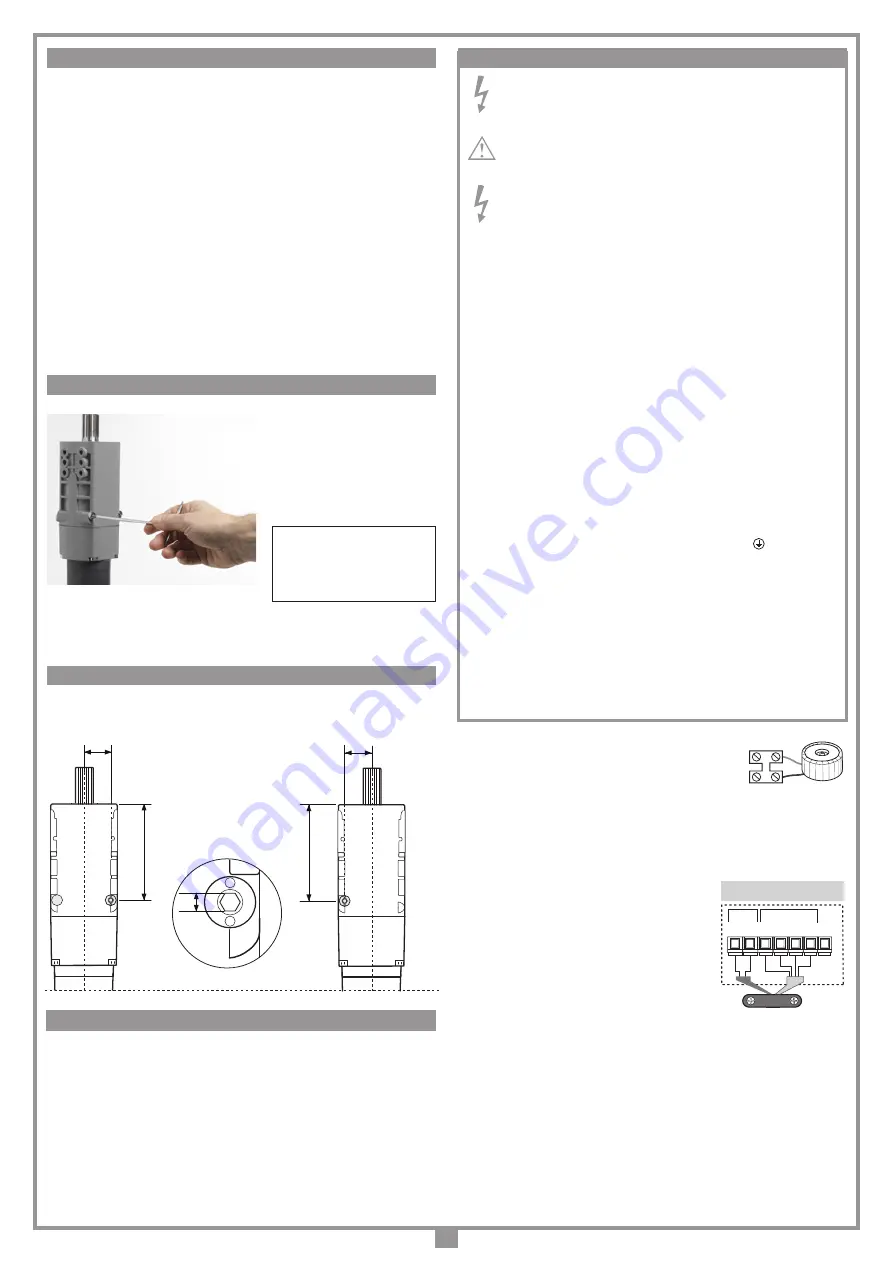

MANUAL RELEASE MECHANISM

RELEASE SYSTEM ACCESS

Manual release system acti-

vated via a 3 mm hexagonal

socket (Allen key 3)

205/BLi924

04-08-2010

DI0539

Description :

Product Code :

Date:

Drawing number :

P.J.Heath

CARDIN ELETTRONICA S.p.A - 31020 San Vendemiano (TV) Italy - via Raffaello, 36 Tel: 0438/401818 Fax: 0438/401831

Draft :

All rights reserved. Unauthorised copying or use of the information contained in this document is punishable by law

AUTOMAZIONE INTEGRATO PER CANCELLI

A BATTENTE

115

33

3

109

33

Side A

Side B

An access slot will have to be built into the column for the release mechanism.

Summary of Contents for 305/GLi824

Page 2: ...2 NOTES ...

Page 12: ...12 NOTES ...

Page 20: ...20 NOTES ...

Page 28: ...28 NOTES ...

Page 36: ...36 NOTES ...