8527-0544-2M Rev B

APS Enterprise Scale

2

INSTALLATION

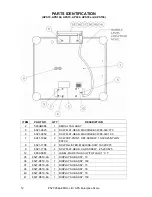

Unpacking (APS10, APS160, APS15 and APS30)

Remove the scale from the shipping carton. Remove all packing material and then examine

the scale to make certain there is no shipping damage. Should damage be discovered contact

the shipping company as soon as possible. The packing material and shipping carton should

be retained for possible examination by the shipping company.

Determine where the scale is to be located. It should be a smooth surface capable of

supporting both the scale and any load to be placed on the scale. It should not be in direct

sunlight nor should it be subject to air flow from heating/cooling vents, fans or similar devices.

Plug-in the 12VDC adapter to use scale. Refer to Electrical Power section of this manual for

more instruction. The scale is now ready for use.

Unpacking and Setup (APS70 and APS150)

1. Remove the scale display, hardware pack, power supply, scale cover and scale base

assembly from the shipping carton. Remove all packing material and then examine the

scale to make certain there is no shipping damage. Should damage be discovered contact

the shipping company as soon as possible. The packing material and shipping carton

should be retained for possible examination by the shipping company.

2. Remove the four leveling feet from the hardware pack and install in each corner of the

bottom of the scale base. NOTE: Leveling feet must be in place to operate the scale.

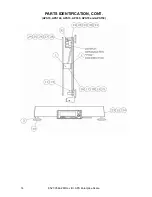

3. To mount the display on the scale base, use the two included mounting screws in the

hardware pack. Insert the screws through the two holes in the scale display bracket and

attach the bracket to the scale base. Route the cable into the scale and plug into scale

display port (see interconnection section for port location and more information).

4. Determine where the scale is to be located. It should be a smooth surface capable of

supporting both the scale and any load to be placed on the scale. It should not be in direct

sunlight nor should it be subject to air flow from heating/cooling vents, fans or similar

devices.

5. Plug-in 12VDC adapter to use scale. Refer to Electrical Power section of this manual for

more instruction.

6. The scale is now ready for use.

Level Adjustment

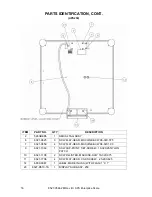

Place the scale in the chosen location and remove the stainless steel platform. The platform

can be removed by lifting upward on it removing it from the weighbridge. Locate the small

level indicator on the scale base to the right of the display and check to make certain that the

scale is level.

NOT

LEVEL

LEVEL

Bubble

is

not

Bubble

is

within

circle

within

circle

If the level indicator does not show a level indication, the

mounting feet should be adjusted to obtain a level

condition. To adjust a mounting foot, first loosen the lock

nut then turn the mounting foot in the required direction to

raise or lower that corner of the scale. Once a level

condition has been achieved, secure the mounting foot

settings by tightening each of the lock nuts. Replace the

platform on the weighbridge.

MOUNTING FOOT

LOCK NUT