E

CLIPSE

,

OEM Installation

Manual

Carefree of Colorado

10

052547-021

M

ULTI

-S

WITCH

I

NSTALLATION AND

W

IRING

1.

Determine the final layout of the switches and the control box and mark the locations.

NOTE:

When using only the wire harnesses furnished, the maximum distance from the cable

point of entry to the relay module is 48”. Maximum distance from the relay module to

the switches is 16”.

2. For installations using the cables with direct

connections (no external plug):

2.1

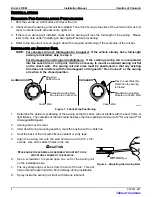

Drill two 5/16” holes

through the vehicle wall for the motor cable

and exterior switch cable. Move the cables

out of the way to avoid damage while drilling.

2.2 Route the cables through the holes to the

location of the relay module.

2.3 Seal the cables and holes using a silicone

sealant.

2.4 Go to step 4.

3. For installations using an external wall mount

plug/receptacle:

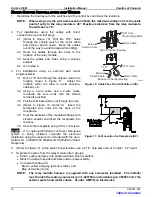

3.1 Drill a 7/8” hole through the exterior wall in the

location shown in Figure 11. Adjust the

location within the area to avoid structure,

cabinetry etc.

3.2 Using a 3-wire cable and a 2-wire cable,

terminate the wire ends with the female

terminals provided.

3.3 Pull the terminated wires out through the hole.

3.4

(Refer to Figure 13, Detail A)

Insert the

terminated wire ends into the back of the

receptacle.

3.5 Coat the backside of the receptacle flange with

silicone sealant and insert the receptacle into

the hole.

3.6 Secure the receptacle using 4 #6 x 1/2 screws.

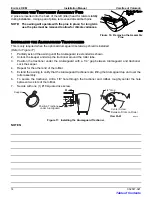

STOP

–

If an optional Windsmart or Direct Response

system is being installed, complete the electrical

installation using the instructions included with the Auto-

Retract kit. (052987-002 Windsmart, 052526-001 Direct

Response)

4.

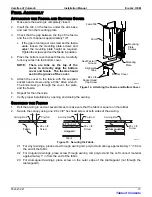

At the switch panel location, use a 2 1/4” hole saw and cut 2 holes 1 1/2” apart.

5. Separate the wires from the relay module into 3 groups:

•

Brown, yellow and gray with spade terminals (interior switch),

•

Black and red with spade terminals (interior power switch),

•

Connector bundle with:

Brown, yellow and gray (exterior switch), and

Blue and white (motor).

NOTE: The relay module harness is supplied with one connector installed. The installer

must furnish the mating connector (p/n 1-480704) and terminals (p/n 350547-3) for the

exterior switch and motor cables. Vendor: AMP/Tyco Electronics.

5/16" Hole

Thru Existing Slots

Top of Channel Routing

Bottom of Channel Routing

E0004

External

Switch Cable

Motor Cable

1 1/2"

Motor Cable

External

Switch Cable

5/16" Hole

Figure 10. Cable Pass Thru Drill Pattern (CS).

Figure 11. Drill Location for Receptacle (SP).

Table of Contents