Carefree of Colorado Installation

Manual

T

RAVEL

'

R

052540-002r4

7

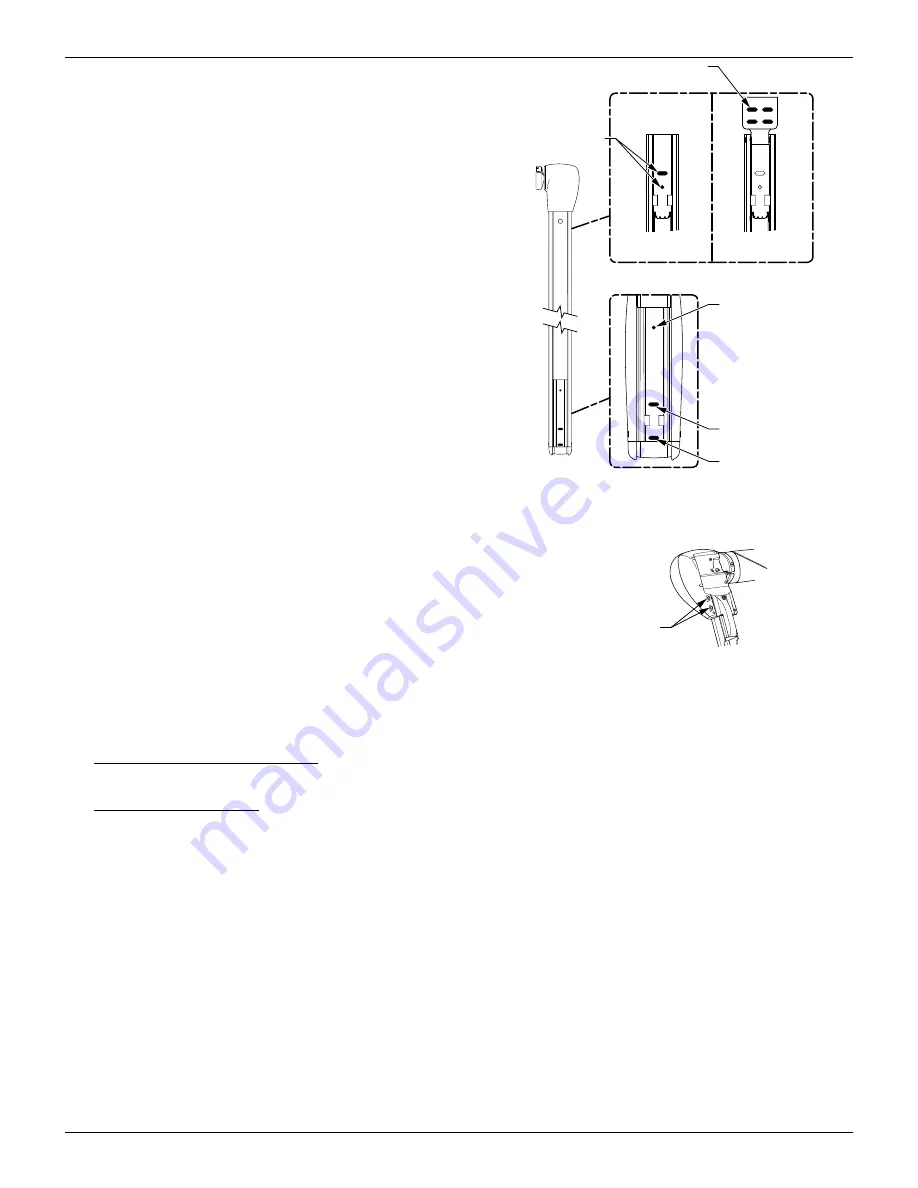

8. Confirm that the arm is perpendicular to the

awning rail, attach the arm through the #1

mounting hole (shown in Figure 8) using a 5/32”

pilot hole and a 1/4 x 1-1/2” lag screw.

9. Position the roller assembly so that it is

perpendicular to the motorized arm assembly.

Position the non-motorized arm perpendicular to

the roller assembly.

10. Drill a 5/32” hole through the #2

mounting hole

and attach the non-motorized arm using a 1/4 x

1 1/2” lag screw.

11. Check the alignment; the arm assembly must be

perpendicular to the roller assembly. When the

alignment is correct, drill and attach the arm

through the #1 mounting hole (shown in Figure

8) using a 5/32” drill bit and a 1/4 x 1-1/2” lag

screw.

12. Hold the awning closed and carefully remove the

plastic wraps at the top of the arms. The awning

will open a few inches.

13. Open the awning about 18” or until the top

mounting holes on the arms are visible. To open

13.1

Cap the exposed end of the wires from the motor cable to

avoid grounding or shorting. These must remain capped

and detached from the switch when using the emergency

terminals.

13.1

Attach the supplied jumper cables to the emergency terminals

located on the back of the motorized head.

13.2 Connect the other ends of the jumper leads to a 12V

source (i.e. drill battery). If the awning does not begin to

move, reverse the leads.

14. Drill 5/32" pilot holes for the upper mounting holes and the #3 lower mounting hole for each arm.

15.

For Aftermarket configurations:

Attach the upper mounting bracket using 2 ea 1/4 x 2 1/2 lag screws.

Attach the #3 lower mounting hole with a 1/4 x 1 1/2 lag screw or moly rivet.

16.

For OEM configurations:

Attach the upper mounting holes using 2 ea 1/4 x 1 1/2 lag screws. Attach the

#3 lower mounting hole with a 1/4 x 1 1/2 lag screw or moly rivet.

Upper Mounting Holes

(Arm Extended Out)

Lower Mounting Holes

#1

Mounting Hole

#2

Mounting Hole

OEM Mounting Holes

1/4 x 1 1/2 Screws Only

TravelR005

#3

Mounting Hole

OEM

Configuration

Aftermarket

Configuration

Aftermarket Mounting Holes

1/4 x 2 1/2 Screws Only

For #1, 2 and 3 use

1/4 x 1 1/2 Screws

or

3/16 Moly Rivets

Figure 8. Arm Mounting Hole Locations.

TravelR010c

Emergency

Terminals

RH Motor Head

Figure 9. Emergency Terminals.